The following sections will delve deeper into the key components of this type of document, offering practical guidance on its creation and implementation within various operational contexts. Specific examples will illustrate its utility in diverse scenarios, highlighting best practices and common pitfalls to avoid.

1. Hazard Identification

Hazard identification forms the foundational element of a robust risk and method statement template. Without a comprehensive understanding of potential hazards, subsequent steps in risk assessment and control measure implementation become ineffective. This process involves systematically examining all aspects of a task or project to identify anything that could cause harm. This includes considering the work environment, equipment used, materials handled, and the individuals involved. For instance, in a laboratory setting, hazard identification might reveal the presence of flammable chemicals, sharp instruments, or biological agents, each requiring specific control measures.

The thoroughness of hazard identification directly impacts the quality and effectiveness of the overall template. A failure to identify a specific hazard prevents the development of appropriate control measures, increasing the risk of incidents. A detailed hazard identification process allows for a proactive approach to safety, reducing the likelihood of reactive responses to accidents or near misses. Consider a construction site: identifying the hazard of working at height before work commences leads to implementing safety harnesses and scaffolding, preventing potential falls.

Effective hazard identification requires a multi-faceted approach, drawing on various sources of information. This may include consulting safety data sheets, conducting site inspections, reviewing accident records, and engaging with workers who possess valuable practical experience. The output of this process informs the subsequent stages of risk assessment and control measure selection within the template, ultimately contributing to a safer and more efficient work environment. Challenges can include overlooking less obvious hazards or underestimating their potential impact. Addressing these challenges requires ongoing training, vigilance, and a commitment to continuous improvement in hazard identification practices.

2. Risk Assessment

Risk assessment is a critical component of any robust risk and method statement template. It provides a structured process for evaluating the potential severity of identified hazards and the likelihood of their occurrence. This analysis informs the selection and implementation of appropriate control measures, enabling proactive risk mitigation. Without a thorough risk assessment, the effectiveness of the overall template is significantly diminished.

- Likelihood and ConsequenceRisk assessment involves evaluating both the likelihood of a hazard leading to an incident and the potential consequences of such an incident. Likelihood can range from rare to almost certain, while consequences can vary from minor injuries to fatalities. For example, in a construction setting, the likelihood of a worker falling from a scaffold might be assessed as ‘likely’ if no safety harness is used, with potentially fatal consequences. This assessment informs the mandatory use of safety harnesses, documented within the template.

- Risk MatrixA risk matrix is a common tool used in risk assessment. It provides a visual representation of the relationship between likelihood and consequence, categorizing risks into different levels (e.g., low, medium, high). Each level corresponds to specific control measures. For example, a high-risk activity, such as working with hazardous chemicals, might require stringent control measures, including specialized training, personal protective equipment, and emergency procedures, all detailed within the template.

- Control HierarchyRisk assessments should consider the hierarchy of controls, prioritizing the most effective measures. Eliminating the hazard altogether is the most effective approach, followed by substitution with a less hazardous alternative. Engineering controls, such as safety guards on machinery, are next, followed by administrative controls, like training programs. Personal protective equipment, such as gloves and goggles, is considered the least effective control and should only be used as a last resort. This hierarchy guides control measure selection within the template.

- Residual RiskEven with control measures in place, some level of risk often remains. This is known as residual risk. The risk assessment process should evaluate and document this residual risk, ensuring it is as low as reasonably practicable (ALARP). For example, even with safety harnesses in use, a residual risk of injury from a fall remains. The template might then stipulate regular harness inspections and training updates to minimize this risk.

By systematically evaluating hazards and their associated risks, the risk assessment process provides a crucial foundation for developing effective control measures and methodical procedures within the risk and method statement template. This structured approach ensures that all potential risks are identified, evaluated, and mitigated, minimizing the likelihood of incidents and promoting a safer work environment. The risk assessment becomes a living document, subject to regular review and updates as conditions change or new information becomes available.

3. Control Measures

Control measures represent the practical application of risk mitigation within a risk and method statement template. Following hazard identification and risk assessment, control measures provide the specific actions and procedures implemented to minimize or eliminate identified risks. Their effective selection and implementation are crucial for ensuring workplace safety and project success. A well-defined set of control measures translates theoretical risk assessment into actionable steps, forming a bridge between identified hazards and safe working practices.

- Hierarchy of ControlsControl measures should adhere to the established hierarchy of controls, prioritizing the most effective methods. Elimination, the most effective approach, involves removing the hazard entirely. Substitution replaces a hazardous material or process with a safer alternative. Engineering controls isolate people from hazards through physical modifications, such as machine guarding. Administrative controls implement safe work practices through procedures, training, and signage. Personal protective equipment (PPE), while necessary in some situations, is considered the least effective control and should be used as a last resort, supplementing higher-level controls.

- Specificity and PracticalityControl measures must be specific and practical, clearly outlining the actions required to mitigate each identified hazard. Vague or impractical control measures render the template ineffective. For example, stating “use appropriate safety equipment” is less effective than specifying “wear safety glasses conforming to ANSI Z87.1 and nitrile gloves when handling corrosive chemicals.” Specificity ensures clarity and facilitates consistent implementation.

- Monitoring and ReviewControl measures require ongoing monitoring and review to ensure their continued effectiveness. Regular inspections, audits, and feedback from workers can identify areas for improvement or highlight the need for adjustments. Changes in work processes, materials, or equipment may necessitate revisions to existing control measures. This dynamic approach ensures the template remains relevant and effective in mitigating evolving risks.

- Documentation and CommunicationClearly documented control measures within the template ensure that all personnel understand their responsibilities and the procedures to follow. Effective communication of these measures is essential, ensuring everyone involved understands the rationale behind them and their importance in maintaining a safe work environment. Regular toolbox talks, training sessions, and readily accessible documentation contribute to a strong safety culture.

Control measures form the practical core of a risk and method statement template, translating risk assessment into actionable steps. Their selection, implementation, monitoring, and communication are crucial for ensuring a safe and productive work environment. A comprehensive and well-maintained set of control measures within the template significantly contributes to successful project completion and the overall well-being of all involved.

4. Methodical Procedures

Methodical procedures form an integral part of a comprehensive risk and method statement template. They provide a structured, step-by-step approach to task execution, minimizing deviations and promoting consistent adherence to established safety protocols. A clearly defined sequence of actions reduces the likelihood of errors and omissions that could contribute to incidents. Well-defined procedures also enhance efficiency by streamlining operations and promoting clarity among personnel.

- Task BreakdownComplex tasks benefit from being broken down into smaller, more manageable steps within the methodical procedures section. This decomposition allows for a more focused approach to risk assessment and control measure implementation at each stage. For instance, a complex laboratory experiment might be broken down into sub-tasks like sample preparation, reagent handling, reaction monitoring, and waste disposal, each with specific procedures and safety considerations detailed in the template.

- Sequencing and DependenciesThe order in which steps are executed within a methodical procedure often carries significant safety implications. Establishing clear dependencies between tasks ensures that critical actions are performed in the correct sequence, minimizing the potential for hazards. Consider a construction project: ensuring the foundation is poured before erecting walls is a critical sequence outlined in the template’s methodical procedures, preventing structural instability.

- Equipment and Resource AllocationMethodical procedures should specify the necessary equipment and resources for each task step. This clarity ensures that the appropriate tools and materials are available when needed, reducing the risk of improvisation or using incorrect equipment, both of which can contribute to incidents. A template for operating heavy machinery, for example, would detail the required safety equipment, operational checks, and maintenance procedures.

- Emergency ProceduresIntegrating emergency procedures within the methodical steps is crucial for managing unforeseen events. Clear instructions for responding to incidents, including evacuation routes, emergency contact information, and first aid procedures, ensure a swift and appropriate response. A laboratory template would include detailed steps for handling chemical spills or equipment malfunctions, ensuring personnel safety.

Methodical procedures, when integrated within a risk and method statement template, transform a general understanding of risks into a practical, actionable plan. This structured approach enhances safety by reducing the likelihood of errors, promotes efficiency by streamlining operations, and contributes to a more controlled and predictable work environment. Regular review and updates of these procedures ensure the template remains relevant and effective as work practices evolve or new information emerges.

5. Documentation and Review

Documentation and review processes constitute a critical, ongoing component of a robust risk and method statement template. They ensure the template remains a living document, adapting to changing circumstances and incorporating lessons learned. Thorough documentation creates a record of hazard identification, risk assessment, control measures, and methodical procedures, providing a valuable resource for training, audits, and incident investigations. Regular review cycles ensure the template’s continued effectiveness and relevance.

- Record KeepingMaintaining comprehensive records of the entire risk assessment process is essential. This includes documenting identified hazards, risk assessment outcomes, implemented control measures, and established methodical procedures. Detailed records provide evidence of due diligence, facilitate training, and support incident investigations. For instance, documenting the rationale behind selecting specific safety equipment ensures future decisions remain aligned with the initial risk assessment.

- Version ControlAs projects evolve or new information emerges, the risk and method statement template requires updates. Implementing a version control system ensures clarity regarding the current, applicable version of the document. Each revision should be documented, outlining the changes made and the rationale behind them. This clear audit trail enhances accountability and facilitates tracking the evolution of risk management strategies.

- Periodic ReviewRegularly scheduled reviews of the template are essential for maintaining its effectiveness. These reviews should involve personnel familiar with the tasks and potential hazards. The review process should assess the adequacy of existing control measures, the effectiveness of methodical procedures, and the accuracy of hazard identification. Regular review cycles might be triggered by changes in legislation, near misses, or incidents, ensuring the template remains current and relevant.

- Communication and TrainingDocumented templates serve as valuable training resources, communicating safe working practices and established procedures to all personnel. Integrating the template into induction programs and ongoing training initiatives ensures everyone understands the identified hazards, associated risks, and implemented control measures. Regular communication reinforces the importance of adherence to the template and promotes a strong safety culture.

Documentation and review are not static elements but rather continuous processes that ensure the risk and method statement template remains a dynamic tool for managing workplace safety. These processes contribute to a cycle of continuous improvement, enhancing the template’s effectiveness in minimizing risks, promoting safe working practices, and fostering a culture of proactive safety management. By embracing documentation and review, organizations demonstrate a commitment to ongoing safety enhancement and effective risk mitigation.

Key Components of a Risk and Method Statement Template

A robust template requires several key components to effectively manage risks and define safe working practices. These components work together to provide a comprehensive approach to hazard identification, risk assessment, and control implementation.

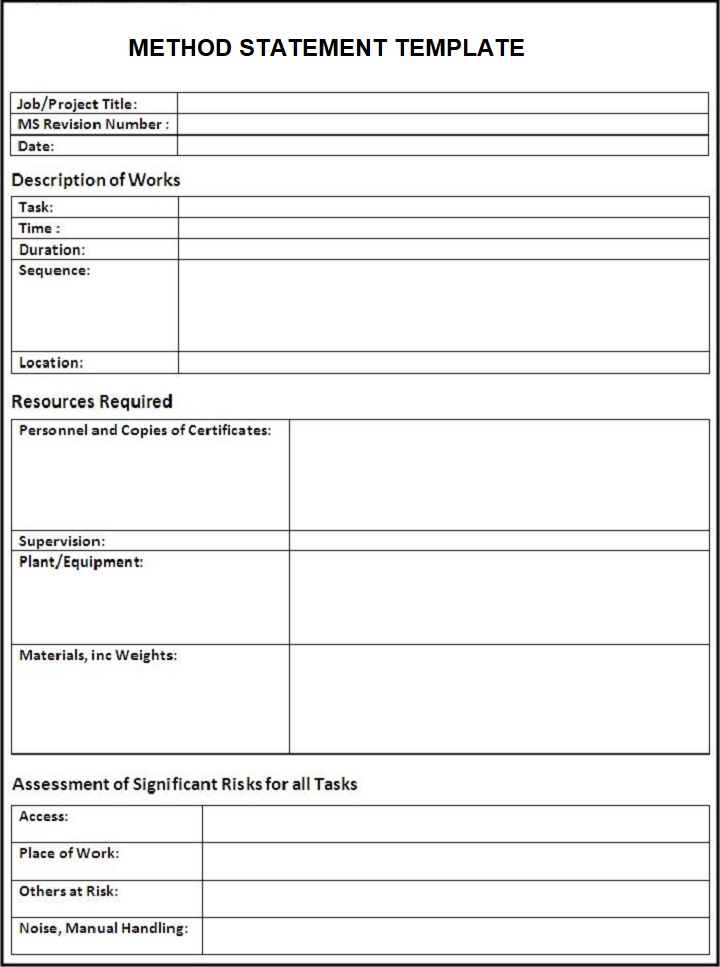

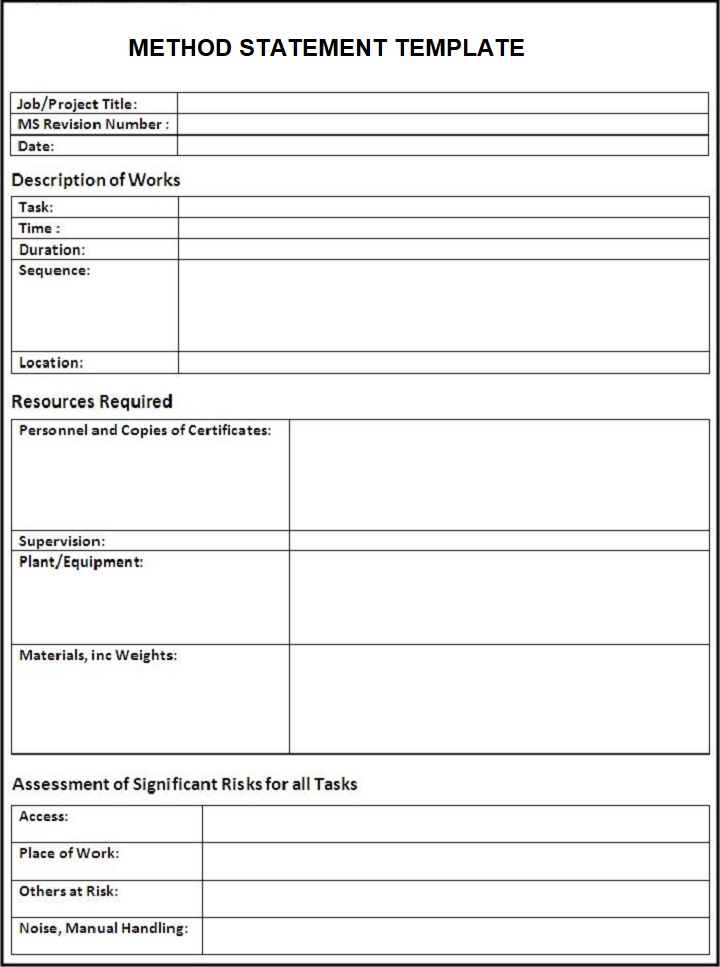

1. Project Information: Clear identification of the project, location, dates, and involved parties is essential for context and traceability.

2. Hazard Identification: A systematic process of identifying all potential hazards associated with the task or project. This includes considering the work environment, equipment, materials, and personnel.

3. Risk Assessment: Evaluation of the likelihood and potential consequences of each identified hazard. This often involves using a risk matrix to categorize risks and prioritize control measures.

4. Control Measures: Specific actions and procedures implemented to eliminate or mitigate identified risks. These measures should adhere to the hierarchy of controls, prioritizing the most effective methods.

5. Methodical Procedures: Step-by-step instructions for carrying out the task safely. This includes task breakdown, sequencing, resource allocation, and emergency procedures.

6. Personal Protective Equipment (PPE): Specification of any required PPE, ensuring it is appropriate for the identified hazards and readily available to personnel.

7. Emergency Procedures: Clear instructions for responding to emergencies, including evacuation routes, contact information, and first aid procedures. This ensures a swift and coordinated response to unforeseen events.

8. Documentation and Review: A system for documenting the entire process, including version control and regular review cycles. This ensures the template remains current and effective.

A comprehensive template ensures informed decision-making, promoting proactive hazard management and contributing significantly to a safer work environment. Regular review and adaptation maintain relevance and effectiveness over time.

How to Create a Risk and Method Statement Template

Creating a robust risk and method statement template requires a systematic approach, ensuring all potential hazards are identified and mitigated. The following steps outline the process:

1. Define the Scope: Clearly define the task or project for which the template is being created. Specify the location, dates, and individuals involved. This provides crucial context for subsequent steps.

2. Identify Hazards: Systematically examine all aspects of the task to identify potential sources of harm. Consider the work environment, equipment, materials, processes, and personnel. Consult relevant safety data sheets, regulations, and industry best practices. Engage workers with practical experience to gain valuable insights.

3. Assess Risks: Evaluate the likelihood and potential consequences of each identified hazard. Utilize a risk matrix to categorize risks based on their potential severity and probability of occurrence. This categorization informs the selection of appropriate control measures.

4. Develop Control Measures: Implement control measures to mitigate identified risks, adhering to the hierarchy of controls. Prioritize eliminating the hazard, followed by substitution, engineering controls, administrative controls, and finally, personal protective equipment. Ensure control measures are specific, practical, and readily implementable.

5. Define Methodical Procedures: Outline a step-by-step procedure for executing the task safely. Break down complex tasks into smaller, manageable steps. Specify the sequence of operations, resource allocation, and any necessary precautions. Incorporate emergency procedures for managing unforeseen events.

6. Specify Personal Protective Equipment (PPE): Detail any required PPE, ensuring its appropriateness for the identified hazards. Provide clear instructions on proper usage, maintenance, and storage of PPE. Regularly inspect PPE to ensure its effectiveness.

7. Outline Emergency Procedures: Develop clear emergency procedures for various scenarios, including fire, chemical spills, medical emergencies, and equipment malfunctions. Provide contact information for emergency services and designated personnel. Conduct regular drills to ensure preparedness.

8. Implement Documentation and Review: Maintain comprehensive documentation of the entire process, including hazard identification, risk assessment, control measures, and methodical procedures. Establish a version control system to track revisions. Schedule regular reviews to ensure the template remains relevant and effective, adapting to changing conditions and incorporating lessons learned.

A well-structured template facilitates proactive hazard management, promoting a safer work environment and contributing to successful project completion. Continuous improvement through regular review and adaptation is essential for maintaining its effectiveness.

Effective management of workplace safety and project success relies heavily on comprehensive risk and method statement templates. These documents provide a structured approach to hazard identification, risk assessment, and the implementation of appropriate control measures. From defining the scope of a project to outlining methodical procedures and emergency protocols, these templates ensure a proactive approach to risk mitigation. Thorough documentation and regular review cycles maintain the template’s relevance and effectiveness in dynamic work environments, fostering a culture of continuous improvement in safety practices. Well-defined procedures, clearly documented within the template, empower personnel with the knowledge and guidance needed to perform tasks safely and efficiently, contributing to overall project success.

Proactive risk management, facilitated by meticulously crafted and consistently reviewed risk and method statement templates, is not merely a regulatory requirement but a fundamental element of responsible operational practice. The commitment to continuous improvement in hazard identification, risk assessment, and control measure implementation, reflected in these documents, ultimately determines the long-term success and sustainability of any organization. Investing in robust templates and their continuous refinement translates directly into enhanced safety outcomes, reduced incidents, and a more secure and productive work environment for all.