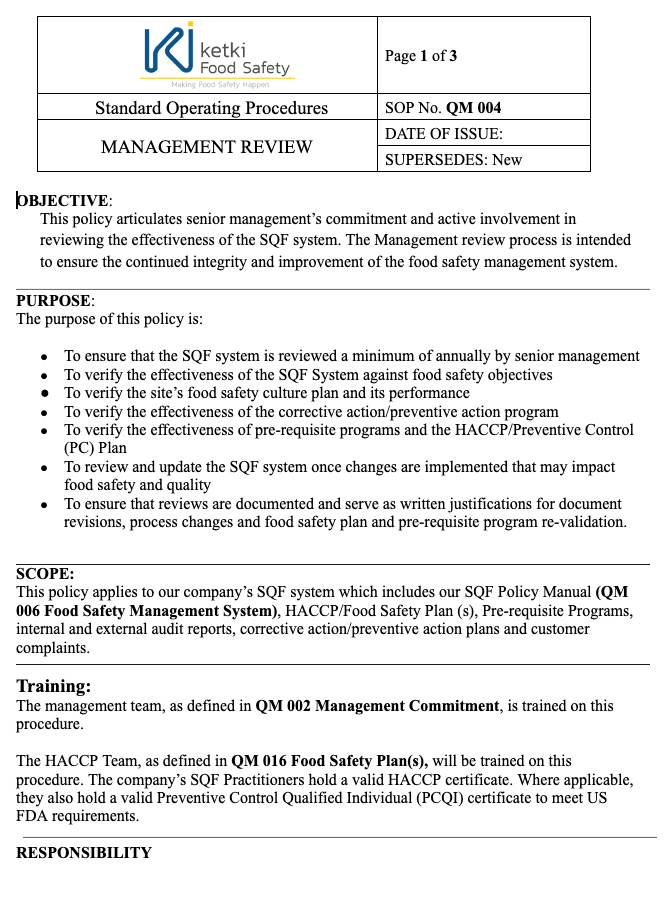

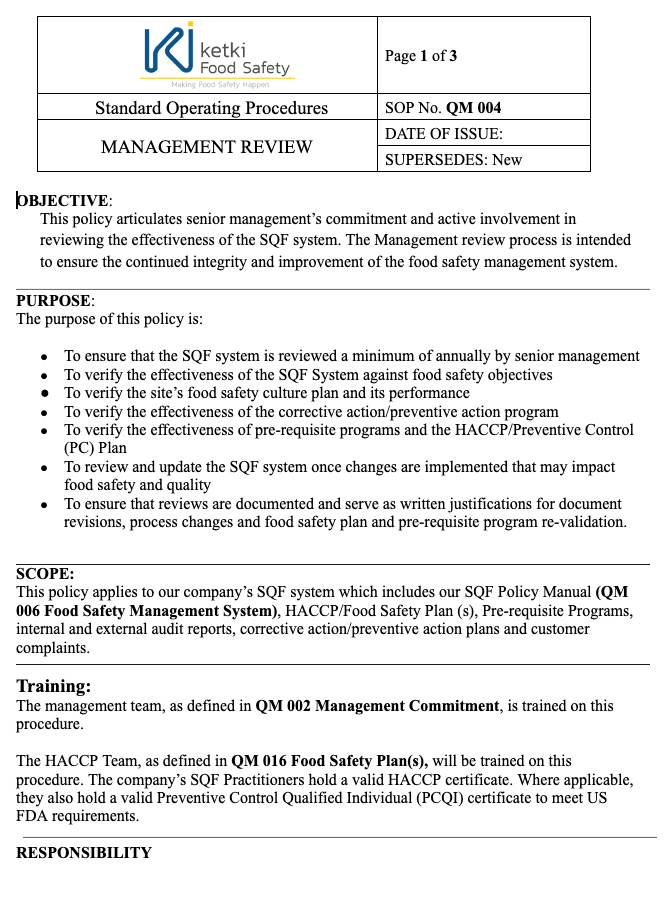

In the complex world of food safety and quality, ensuring that your operations meet the highest standards is paramount. The Safe Quality Food (SQF) Program is a rigorous, globally recognized food safety and quality certification system, and it demands meticulous attention to detail in every aspect of your production process. One area that often gets overlooked, yet is absolutely critical for compliance and continuous improvement, is how you manage customer feedback, especially complaints. A well-structured system for handling these inputs isn’t just good business practice; it’s a cornerstone of SQF compliance.

Think about it: every customer complaint, no matter how minor, presents an opportunity. It’s a chance to identify potential issues with your product or process, prevent recurrence, and ultimately strengthen your relationship with your customers. For businesses operating under SQF certification, having a systematic approach to logging, investigating, and resolving complaints is not optional. It’s a mandatory part of maintaining your certification, directly addressing SQF Code elements related to customer complaints and corrective actions. This is where an effective sqf customer complaint form template becomes an invaluable tool in your quality management arsenal.

The Essential Elements of a Robust SQF Customer Complaint Form

Creating a form might seem straightforward, but for an SQF-certified facility, it needs to be far more than just a blank sheet of paper. Your form must be designed to capture all the necessary information for a thorough investigation, facilitate root cause analysis, and ensure proper corrective actions are taken and documented. It needs to be user-friendly for whoever is logging the complaint, but comprehensive enough to satisfy auditor requirements. This blend of practicality and compliance is key to its effectiveness in an SQF environment.

Beyond merely recording the complaint, the form should guide your team through the investigative process. It needs dedicated sections for documenting the immediate actions taken, the results of any product testing or batch review, and the conclusions drawn from your investigation. Without these structured fields, it becomes challenging to demonstrate a controlled and consistent approach to handling feedback, which is exactly what SQF auditors will be looking for when reviewing your customer complaint procedures.

Key Data Points to Include

When developing your sqf customer complaint form template, ensure it meticulously captures the following critical pieces of information. This isn’t just about ticking boxes; it’s about gathering the necessary data to understand the issue fully and prevent its reoccurrence.

- **Date and Time of Complaint**: When was the complaint received?

- **Customer Information**: Who is the complaint from? (Name, contact details, company).

- **Product Information**: What product is involved? (Product name, lot/batch number, production date, expiry date, quantity affected).

- **Nature of Complaint**: A clear description of the issue (e.g., foreign material, off-flavor, packaging defect, illness report).

- **Severity Assessment**: An internal ranking of the complaint’s seriousness (e.g., minor, major, critical).

- **Investigation Details**: Who investigated? What was found? Include references to internal test results or production records.

- **Root Cause Analysis**: What caused the problem? (e.g., equipment malfunction, human error, supplier issue).

- **Corrective and Preventive Actions**: What steps were taken to resolve the current issue and prevent future occurrences?

- **Verification of Effectiveness**: How was it confirmed that the actions taken were successful?

- **Communication with Customer**: When and how was the customer informed of the resolution?

- **Complaint Status**: Open, Closed, Pending.

Each of these fields serves a purpose, contributing to a comprehensive record that not only satisfies SQF requirements but also provides valuable insights for your continuous improvement programs. A well-designed form makes it easier to track trends, identify recurring issues, and demonstrate a proactive commitment to food safety and quality.

Implementing Your SQF Customer Complaint System for Success

Having a stellar sqf customer complaint form template is only half the battle. The real value comes from how you implement and utilize it within your broader quality management system. The process begins the moment a complaint is received, whether by phone, email, or through a dedicated web portal. Prompt acknowledgment and logging of the complaint are crucial, as delays can escalate issues and undermine customer trust. Your team needs clear procedures on who is responsible for receiving, documenting, and initiating the investigation for each type of complaint.

Once logged, the investigation phase kicks in. This isn’t just about finding a quick fix; it’s about digging deep to understand the "why" behind the complaint. This involves gathering all relevant information, reviewing production records, conducting product analysis if necessary, and potentially even interviewing personnel involved in the product’s manufacturing or distribution. The goal is to identify the true root cause, not just the symptom, so that effective corrective actions can be put in place.

Root cause analysis is a vital part of this process. Without understanding the fundamental reason an issue occurred, any corrective actions you take might only offer a temporary band-aid solution. Techniques like the "5 Whys" or fishbone diagrams can be incredibly useful here. Once the root cause is identified, specific corrective actions (to fix the immediate problem) and preventive actions (to stop it from happening again) must be determined and implemented.

Finally, the cycle isn’t complete until the effectiveness of these actions is verified and the customer is appropriately communicated with. Verification ensures that your efforts actually solved the problem and that the solution is sustainable. Communicating with the customer not only builds goodwill but also closes the loop on their feedback, demonstrating your commitment to their satisfaction and the quality of your products. Regularly reviewing your complaint data can reveal patterns and systemic issues, driving continuous improvement efforts across your entire operation and reinforcing your commitment to SQF principles.

Effectively managing customer complaints is more than just a regulatory hurdle; it’s a strategic advantage. By adopting a comprehensive approach, supported by a well-designed form and robust procedures, you not only meet the stringent requirements of the SQF Code but also build stronger customer relationships and foster a culture of excellence within your organization. This proactive stance ensures that every piece of feedback, even critical one, becomes a stepping stone towards greater operational efficiency and enhanced product safety.