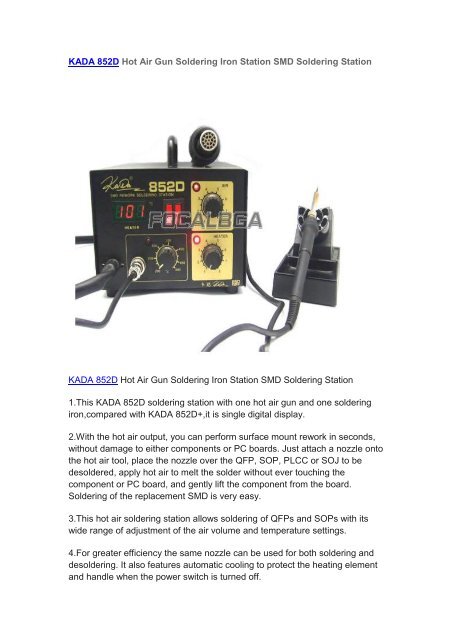

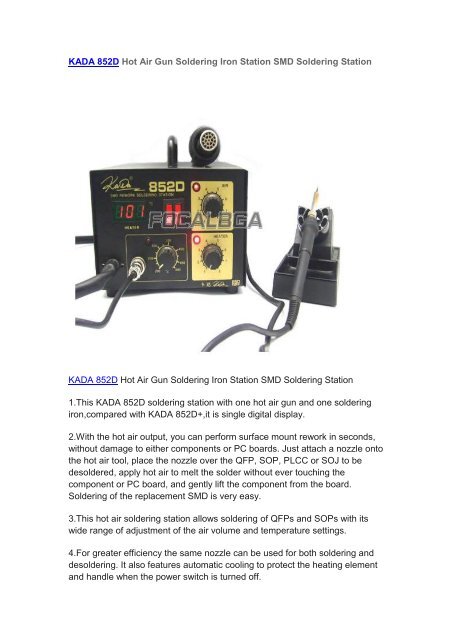

Performing surface mount device (SMD) rework is an intricate process that demands precision, consistency, and a keen eye for detail. Unlike simple soldering, dealing with miniature components on a delicate circuit board requires a methodical approach to ensure the integrity of the board and the functionality of the device. Without a clear, standardized procedure, the quality of rework can vary wildly, leading to costly errors, re-dos, and ultimately, wasted time and resources.

This is where a structured framework becomes invaluable. Implementing a reliable system for tracking each step, evaluating the quality of work, and documenting outcomes can transform a chaotic rework station into a highly efficient and reliable operation. It’s about bringing clarity and accountability to a critical aspect of electronics manufacturing and repair, ensuring that every rework task meets the highest possible standards.

Why a Structured Smd Rework Process is Crucial

The very nature of SMD rework, involving tiny components and precise heat application, means there’s little room for error. A single misplaced component, an incorrectly applied solder paste, or even slight overheating can render an entire board useless. This inherent risk underscores the absolute necessity of a robust, standardized process that minimizes variability and maximizes successful outcomes, protecting both your investment and your reputation.

Standardization brings a multitude of benefits, from reducing the incidence of human error to significantly improving overall efficiency. When every technician follows the same clear steps, it eliminates guesswork and ensures that best practices are consistently applied. This uniformity not only speeds up the rework process itself but also makes troubleshooting easier, as deviations from the standard become immediately apparent.

At the heart of this standardization lies the powerful concept of an smd rework scale form template. This isn’t just a simple checklist; it’s a comprehensive tool designed to guide technicians through every phase of the rework operation, from initial assessment to final quality checks. It serves as a living document that captures critical data, helps in grading the quality of the rework, and provides a historical record for future reference or audit. It’s the backbone of a reliable rework department.

Beyond immediate operational benefits, such a template plays a vital role in training new personnel and ensuring compliance with industry standards. It provides a clear educational pathway for understanding proper techniques and quality expectations. Furthermore, for companies operating under strict quality certifications, having a documented and measurable rework process is often a mandatory requirement, and a well-designed template fulfills this need perfectly.

Key Elements to Include in Your Template

When designing your own smd rework scale form template, consider incorporating these essential components to maximize its effectiveness:

- Pre-Rework Checklist: Before any work begins, ensure vital steps like safety checks, component verification, and tool preparation are completed. This prevents overlooking crucial initial setup tasks.

- Procedure Steps: Detail each step of the rework process, from desoldering to component placement and reflow, along with specific parameters (e.g., temperature profiles, dwell times).

- Quality Assurance Scales: Implement a grading system (e.g., A, B, C or numerical scores) for various aspects of the rework, such as solder joint quality, component alignment, and cleanliness. This allows for objective assessment.

- Documentation Fields: Include sections for recording details like rework date, technician name, board serial number, component replaced, any issues encountered, and final inspection results. This creates a valuable historical log.

Implementing and Customizing Your Rework Template

Bringing a new smd rework scale form template into your workflow requires a thoughtful implementation strategy. Begin by assessing your current rework procedures, identifying bottlenecks, common errors, and areas where consistency is lacking. This initial analysis will provide valuable insights into what specific challenges your template needs to address and what existing best practices can be formalized.

Once you have a baseline understanding, you can design or adapt a template that truly fits your unique operational needs. Remember, a template is a living document, not a rigid instruction manual that applies universally without modification. Different types of boards, component packages, or even specific customer requirements might necessitate variations. For instance, rework on a high-density, fine-pitch BGA might require more detailed checks and specific thermal profiles than a larger, through-hole component.

Crucially, the success of any template hinges on the team using it. Comprehensive training for your technicians is paramount. This training should cover not just how to fill out the form, but also the “why” behind each section – explaining how each step contributes to overall quality and efficiency. Practical sessions where technicians use the template in a simulated rework environment can help solidify their understanding and address any initial concerns.

Finally, integrating the template into your daily workflow should be a continuous improvement process. Start with a pilot phase on a limited number of rework tasks, gather feedback from the technicians, and be prepared to refine the template based on their practical experiences. Regular reviews, perhaps quarterly or semi-annually, will ensure the template remains relevant, effective, and adapts to new technologies or improved techniques. This iterative approach ensures your template evolves with your operational needs.

Embracing a systematic approach to smd rework, underpinned by a well-designed template, is a strategic move that pays dividends. It transforms a potentially unpredictable task into a controlled, high-quality operation, significantly reducing failures and enhancing product reliability. This dedication to precision not only safeguards your output but also builds confidence in your team’s capabilities.

Ultimately, investing time in developing and implementing such structured processes reflects a commitment to excellence. It ensures that every electronic component, no matter how small, receives the meticulous attention it deserves, leading to superior final products and a reputation for consistent, high-quality work in the demanding world of electronics manufacturing and repair.