In today’s competitive marketplace, ensuring product or service quality isn’t just a good practice; it’s absolutely essential for customer satisfaction and long-term business success. Without a structured approach, it’s easy for critical details to slip through the cracks, leading to costly reworks, returns, and damage to your brand reputation. This is where a robust system for checks and balances, often facilitated by a comprehensive tool, becomes invaluable.

That’s precisely why many businesses are turning to a well-designed quality control inspection form template. Such a template provides a standardized framework for evaluating products or processes at various stages, ensuring every necessary step is followed and every standard is met. It streamlines the entire inspection process, makes it repeatable, and helps maintain a consistent level of quality across all your operations, ultimately saving time, reducing waste, and bolstering your bottom line.

The Backbone of Quality: What Makes a Great Inspection Form?

A truly effective inspection form isn’t just a simple checklist; it’s a strategic tool designed to capture critical information, guide inspectors, and provide actionable insights. It needs to be comprehensive yet intuitive, ensuring that all relevant data points are covered without overwhelming the user. The goal is to make the inspection process as efficient and thorough as possible, transforming what could be a tedious task into a clear, measurable activity. It should serve as a historical record, a training tool, and a blueprint for continuous improvement.

Think about the sheer volume of details involved in any production or service delivery. From raw materials to finished goods, or from initial client brief to project completion, there are numerous touchpoints where quality can either be maintained or compromised. A powerful template acts as your guardian, ensuring that each of these points is methodically assessed, deviations are noted, and corrective actions are triggered promptly. It transforms subjective observations into objective, documented data, which is crucial for accountability and analysis.

Key Elements to Look For

When you’re searching for or creating your ideal quality control inspection form template, several elements are absolutely non-negotiable. These components ensure that the form is not only easy to use but also incredibly effective at capturing all necessary information.

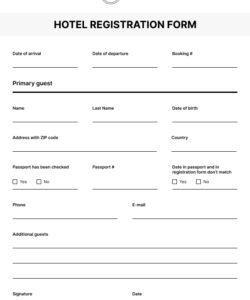

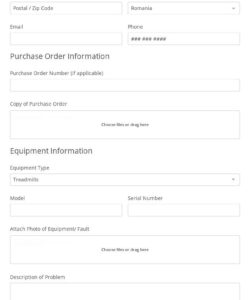

- **Clear Identification Fields:** This includes spaces for product name, batch number, inspector’s name, date, time, and location of inspection. Without these, your data becomes meaningless.

- **Defined Inspection Points/Criteria:** A clear list of what needs to be inspected, often broken down into categories (e.g., visual, functional, dimensional).

- **Pass/Fail or Graded Options:** Simple checkboxes or dropdowns to indicate whether each point meets the standard, or a more granular rating system if applicable.

- **Observation/Notes Section:** A crucial area for inspectors to add detailed comments, describe issues, or provide context for their findings.

- **Corrective Action Section:** Space to document what steps were taken or need to be taken to address identified non-conformities.

- **Sign-off/Approval:** Sections for the inspector and any approving personnel to sign, verifying the completion and accuracy of the inspection.

Beyond these core elements, consider the flexibility of the template. Can it be easily customized to suit different products, processes, or industry-specific regulations? The best forms are adaptable, allowing you to tailor them to your unique operational needs without having to start from scratch every time. Whether you opt for a paper-based system or a digital solution, the underlying structure of a well-designed template is paramount. Digital templates, in particular, offer advantages like real-time data capture, automated reporting, and easier data analysis, but even a simple printable quality control inspection form template can make a world of difference.

Streamlining Your Operations with a Smart Template

Adopting a meticulously crafted quality control inspection form template doesn’t just improve isolated checks; it fundamentally streamlines your entire operational workflow. By standardizing the inspection process, you reduce ambiguity and ensure that every team member follows the same rigorous procedures, regardless of who is performing the check. This consistency is vital for maintaining high standards and avoiding the pitfalls of human error or subjective interpretation. When every inspector uses the same criteria and documentation method, the data collected becomes far more reliable and comparable.

Moreover, a standardized template makes training new staff considerably easier. Instead of relying on tribal knowledge or ad-hoc instructions, new hires can be quickly brought up to speed on your quality protocols by simply following the clearly laid-out steps in the form. This reduces the learning curve, improves efficiency from day one, and ensures that your quality standards are consistently upheld across the entire workforce, fostering a culture of accountability and precision throughout your organization.

One of the most powerful benefits of a robust inspection form is its ability to facilitate meaningful data collection and analysis. When all inspection results are recorded consistently, you gain a wealth of information that can be analyzed to identify trends, pinpoint recurring issues, and uncover root causes of defects. This data-driven approach allows you to move beyond reactive problem-solving to proactive process improvement. You can then make informed decisions on where to invest resources for training, equipment upgrades, or process re-engineering, leading to significant long-term improvements in product quality and operational efficiency.

Ultimately, integrating a comprehensive inspection form into your quality assurance strategy strengthens your compliance efforts and significantly mitigates risks. It provides a documented trail of all quality checks performed, which is invaluable for regulatory audits, internal reviews, and demonstrating due diligence to customers or stakeholders. Should a quality issue arise, you have clear records to trace back, understand where the breakdown occurred, and implement targeted corrective actions. This not only protects your business from potential liabilities but also builds trust and confidence with everyone involved in your supply chain and customer base.