In the world of process safety management, or PSM, one element stands out as particularly critical: Management of Change (MOC). It’s not just a fancy term; it’s a systematic approach to ensure that any alteration, big or small, to facilities, equipment, technology, procedures, or even organizational structure, is carefully evaluated and controlled to prevent unforeseen hazards. Without a robust MOC process, even minor adjustments can lead to significant incidents, impacting safety, the environment, and operational continuity.

Navigating the complexities of MOC can be challenging, especially when considering all the necessary steps from initiation to pre-startup safety reviews and beyond. This is where a well-designed psm management of change form template becomes an invaluable tool. It provides a structured framework, ensuring consistency and thoroughness in every change implemented, making the entire process more manageable and significantly safer. Let’s delve into why such a template is essential and how it can revolutionize your safety protocols.

The Cornerstone of Change Control: Why Your Organization Needs a Solid Template

Managing change effectively within a PSM framework is paramount for maintaining safety and preventing incidents. Any deviation from established designs, operating parameters, or procedures, no matter how minor it might seem, has the potential to introduce new hazards or exacerbate existing ones. This is precisely why the Management of Change process exists: to systematically identify, assess, and control these risks before they lead to undesirable outcomes. It acts as a safety net, ensuring that every proposed change undergoes rigorous scrutiny.

A standardized psm management of change form template serves as the backbone of this critical process. It brings consistency, clarity, and accountability to every step. Imagine a scenario where different departments use their own informal methods to manage changes; the risk of overlooking crucial steps, inadequate documentation, or inconsistent hazard assessments would skyrocket. A template, however, guides users through a predefined sequence of actions, ensuring that no essential safety check or authorization is missed. It acts as a checklist, a communication tool, and a record-keeping system all rolled into one, significantly reducing the potential for human error and ensuring regulatory compliance.

Moreover, a comprehensive template ensures that all facets of a change are considered. It’s not just about the technical modifications; it’s about evaluating the impact on operational procedures, the need for new training for personnel, the integrity of safety systems, and the necessary documentation updates. By prompting users to think through these various aspects, the template fosters a holistic approach to change management, preventing isolated changes from creating ripple effects that compromise overall process safety. It provides a clear audit trail, demonstrating due diligence and a proactive commitment to safety.

Implementing a robust psm management of change form template streamlines the entire MOC workflow. It clarifies responsibilities, sets clear expectations, and facilitates smoother communication among all stakeholders involved—from the initiator of the change to the technical reviewers, safety personnel, and management. This structured approach helps in identifying potential problems early, allocating resources efficiently, and ensuring that changes are implemented safely and effectively without disrupting ongoing operations or compromising personnel well-being.

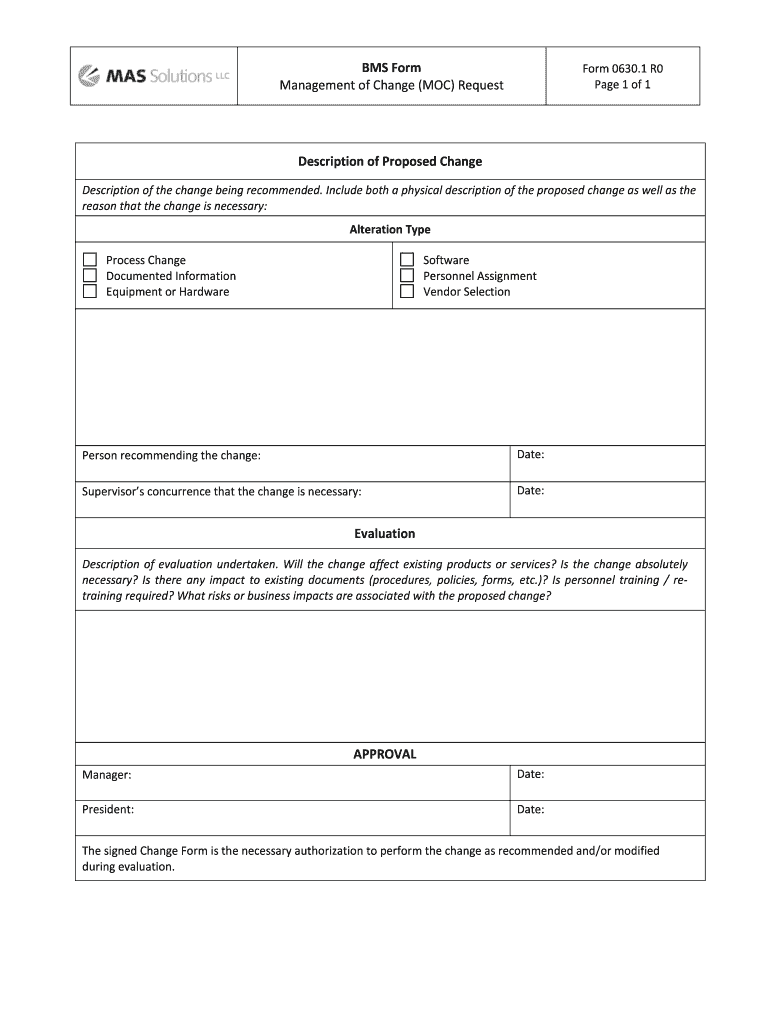

Key Elements of a Robust MOC Form

- **Description of Change:** A clear, concise explanation of what is being changed.

- **Reason for Change:** Justification for the change, including benefits and objectives.

- **Technical Review:** Assessment by qualified personnel to ensure technical feasibility and safety.

- **Hazard Analysis:** Identification of new or increased hazards associated with the change.

- **Authorization Signatures:** Approval from all necessary parties, including management and safety.

- **Training Requirements:** Identification of new training needs for affected personnel.

- **Pre-Startup Safety Review (PSSR):** A final review before startup to confirm all MOC steps are complete.

- **Documentation Updates:** Ensuring all relevant documents (P&IDs, operating procedures) are revised.

Crafting Your Own MOC Form: Best Practices for Customization and Implementation

While a generic psm management of change form template provides an excellent starting point, the true power lies in customizing it to fit the unique needs and complexities of your specific organization and industry. No two facilities are exactly alike, and therefore, a one-size-fits-all approach to MOC might leave gaps or create unnecessary bureaucracy. The goal is to develop a template that is comprehensive enough to capture all essential information yet flexible enough to be practical and user-friendly for your specific operational context. This involves careful consideration of your processes, equipment, regulatory obligations, and organizational culture.

When tailoring your template, consider factors such as the type of processes you operate—be it chemical manufacturing, refining, or power generation—each with its distinct set of hazards and regulatory requirements. The size and complexity of your operations will also influence the level of detail required in the form. A smaller facility might require a more streamlined template, while a large, complex plant might need more detailed sections for risk assessments, compliance checks, and interdepartmental approvals. Involving a cross-functional team, including engineers, operators, safety personnel, and maintenance staff, during the customization phase is crucial to ensure that the template addresses all practical aspects of change management and fosters a sense of ownership among users.

Once your customized template is developed, the implementation phase is critical for its success. It’s not enough to simply introduce a new form; effective implementation requires a comprehensive strategy. This includes providing thorough training to all personnel who will be initiating, reviewing, or approving changes, ensuring they understand the importance of the MOC process and how to correctly use the template. Establishing clear roles and responsibilities for each step of the MOC process is equally important, so everyone knows exactly what is expected of them and who to consult at each stage. Consider piloting the new template with a few less critical changes first to iron out any unforeseen issues before full-scale deployment.

Finally, remember that the MOC process, and by extension, your psm management of change form template, should not be a static document. It’s a living tool that needs continuous review and improvement. Regularly audit your MOC process to identify areas for enhancement, gather feedback from users, and adapt the template as your operations evolve, new technologies emerge, or regulatory requirements change. This commitment to continuous improvement ensures that your MOC system remains effective, efficient, and continues to contribute significantly to your organization’s overall safety performance and operational excellence.

A well-crafted and diligently applied psm management of change form template isn’t just a piece of paper; it’s a vital component of a resilient safety culture. It transforms a potentially chaotic process into a controlled and predictable one, significantly reducing the risks associated with alterations to your systems and processes. By standardizing your approach to change, you create a safer working environment for everyone involved, minimize operational disruptions, and ensure consistent adherence to best practices and regulatory mandates.

Embracing a systematic approach to MOC with a tailored template empowers your organization to manage change proactively, rather than reactively. It enables you to identify and mitigate potential hazards before they escalate, fostering an environment where safety is integrated into every decision. Taking the time to develop and properly implement such a tool is an investment that pays dividends in terms of enhanced safety, improved efficiency, and peace of mind.