Embarking on a journey of process improvement can feel like navigating a complex maze, especially when you are aiming for operational excellence. Lean Six Sigma provides a powerful methodology for organizations looking to streamline operations, reduce waste, and enhance overall quality. It offers a structured approach to problem-solving, guiding teams through a systematic process to identify root causes of inefficiencies and implement lasting solutions.

Successfully implementing these robust methodologies requires more than just understanding the principles; it demands consistent application and meticulous documentation. This is where a well-designed lean 6 sigma form template becomes an invaluable asset, ensuring every step of your improvement project is captured, analyzed, and communicated effectively. It acts as a roadmap, guiding your team through each phase and providing a standardized framework for data collection and analysis.

The Essential Role of a Lean Six Sigma Form Template in Process Improvement

Imagine trying to build a complex structure without blueprints or a consistent set of tools. It would be chaotic, prone to errors, and incredibly inefficient. Similarly, tackling complex business processes without a standardized approach to documentation can lead to missed insights, inconsistent data, and ultimately, failed improvement initiatives. A robust lean 6 sigma form template provides that crucial blueprint, ensuring every project, regardless of its scale or the team involved, adheres to a consistent standard of data collection and analysis.

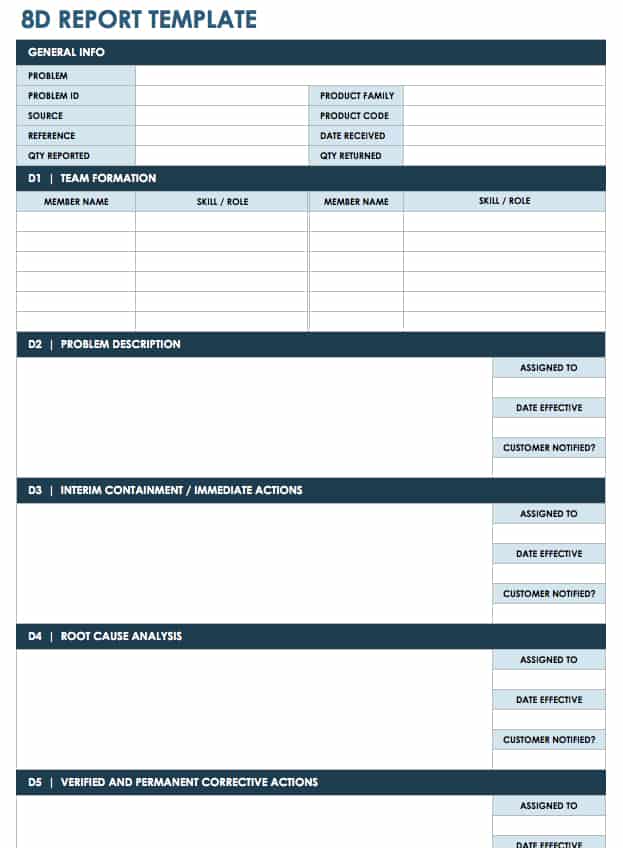

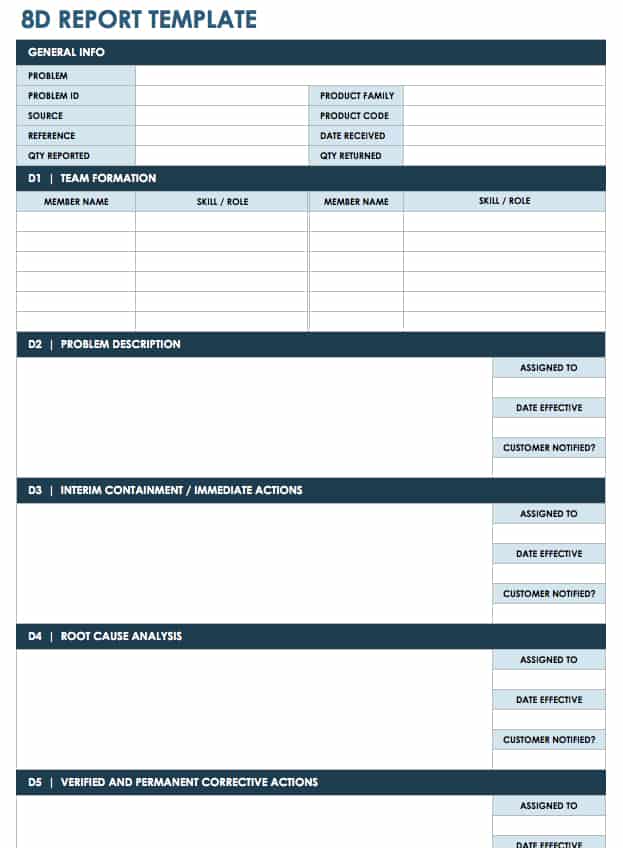

These templates are not just about filling in blanks; they are designed to mirror the phases of the DMAIC (Define Measure Analyze Improve Control) methodology, making it easier for teams to follow the prescribed steps. They prompt you to ask the right questions at the right time, ensuring critical information is captured from the initial project definition all the way through to the control plan. This structured approach significantly reduces the risk of overlooking vital details, which could otherwise derail an entire improvement effort.

Key Elements You’ll Find in a Robust Template

A comprehensive lean 6 sigma form template is typically a collection of various forms and sheets, each serving a specific purpose within the DMAIC cycle. These tools ensure that every piece of information, from high-level project goals to granular process data, is systematically recorded. This meticulous documentation is vital for accurate analysis and for creating a traceable record of improvements.

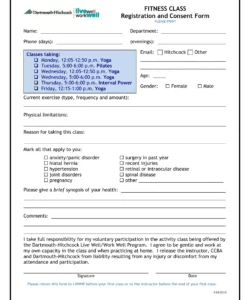

- Project Charter Template for defining scope, goals, and team roles.

- Process Map or Value Stream Map Template to visualize current processes.

- Data Collection Plan Template for outlining what data to gather and how.

- Fishbone Diagram or 5 Whys Template for root cause analysis.

- FMEA Failure Mode and Effects Analysis Template for risk assessment.

- Control Plan Template for sustaining improvements.

By integrating these standardized forms, organizations can ensure that every team member, from Green Belts to Black Belts, is speaking the same language and following the same rigorous procedures. This not only enhances the quality of data and analysis but also fosters a culture of consistency and accountability across all process improvement initiatives. It truly streamlines communication and makes tracking progress straightforward.

Customizing Your Lean Six Sigma Form Template for Maximum Impact

While off-the-shelf templates provide an excellent starting point, the real power of a lean 6 sigma form template comes from its adaptability. Every organization is unique, with distinct processes, challenges, and cultural nuances. A template that works perfectly for a manufacturing plant might need significant adjustments to be effective in a service industry, for instance. The key is to see these templates not as rigid dogma, but as flexible frameworks that can be tailored to fit your specific operational context.

Thinking about your specific project needs is crucial. Are you focusing on reducing customer complaints, optimizing a supply chain, or improving employee onboarding? Each of these areas will require slightly different metrics and data points. By identifying the unique aspects of your project and the data critical to its success, you can customize the template to capture precisely what is most relevant, avoiding unnecessary data collection that can lead to information overload.

- Understand your project scope and specific industry requirements.

- Identify the key metrics and data points essential for your analysis.

- Involve your project team in the customization process for better buy-in.

- Pilot test the customized template on a small scale before full deployment.

- Be prepared to iterate and refine the template based on feedback and results.

A well-customized template enhances user adoption and ensures that the forms are intuitive and relevant to those who will be using them daily. When team members find the forms easy to use and directly applicable to their tasks, they are more likely to complete them accurately and consistently. This leads to higher quality data, more reliable analysis, and ultimately, more successful improvement projects.

Furthermore, consider the format of your template. While printable paper forms have their place, digital versions offer significant advantages in terms of data aggregation, analysis, and sharing. Leveraging software solutions or even simple spreadsheets can transform your customized forms into powerful data collection tools that integrate seamlessly with other analytical platforms, making your Lean Six Sigma efforts even more impactful and efficient.

Implementing a structured approach to process improvement is a fundamental step towards achieving operational excellence and fostering a culture of continuous improvement within any organization. By providing a clear and consistent framework, these tools empower teams to effectively tackle complex challenges, drive measurable results, and sustain long-term gains in efficiency and quality. They transform abstract methodologies into tangible, actionable steps.

The strategic use of a robust and well-adapted lean 6 sigma form template serves as a cornerstone for successful change. It ensures that every effort, from problem identification to solution implementation and control, is documented with precision, enabling clearer communication, more accurate analysis, and ultimately, a more impactful journey towards business excellence. Embracing these standardized yet flexible tools is truly a smart investment in your organization’s future.