Working at significant heights in high-rise environments demands an unwavering commitment to safety. Every piece of equipment, especially those critical for fall protection like safety straps, must function flawlessly. The integrity of these straps isn’t just a matter of compliance; it’s literally a matter of life and death for the professionals who rely on them daily. Without a systematic approach to checking their condition, even the smallest defect could lead to catastrophic consequences.

Managing safety equipment inspections across multiple floors and various work teams can be a complex task. That’s where a standardized tool becomes invaluable. A well-designed high rise strap inspection form template provides a structured method to ensure every critical detail is examined, recorded, and acted upon. It transforms a potentially haphazard check into a rigorous, documented process, offering peace of mind and significantly enhancing overall safety protocols.

The Indispensable Role of a Standardized High-Rise Strap Inspection Template

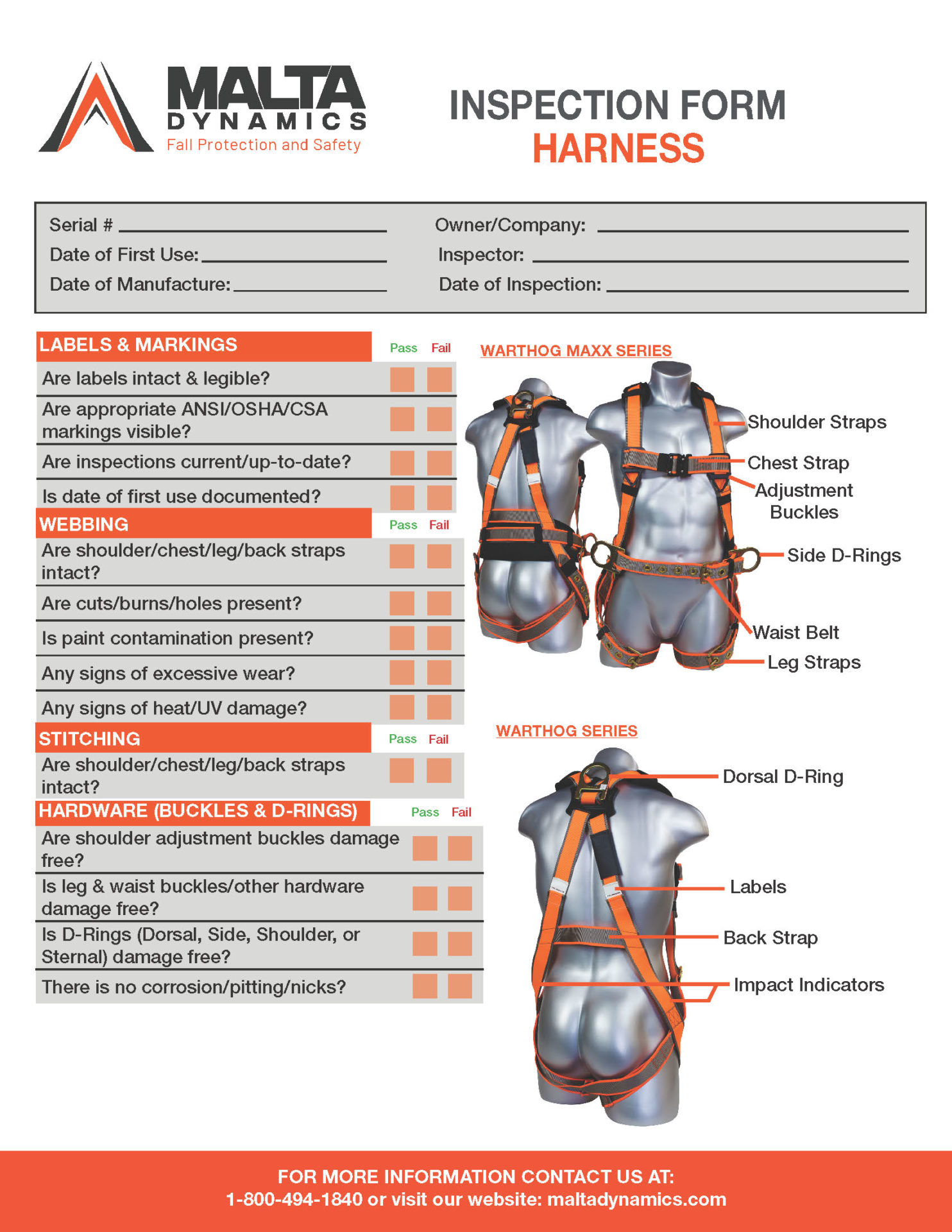

In the challenging world of high-rise construction and maintenance, where workers are exposed to dynamic weather conditions, immense heights, and constant equipment usage, the wear and tear on safety gear is considerable. Straps, whether part of a harness, lanyard, or rescue system, are continuously subjected to stress, abrasion, and environmental elements. Relying on visual checks alone or inconsistent reporting can leave dangerous gaps in your safety net. A dedicated inspection form provides a clear, step-by-step checklist, ensuring no critical component or potential defect is overlooked during routine checks.

This consistency is vital for maintaining a high standard of safety across all operations. When every inspector follows the same procedure and records information in the same format, it creates a reliable data stream. This data is not just for compliance; it’s a powerful tool for proactive maintenance and risk management. It allows safety managers to identify trends, predict equipment failures, and schedule timely repairs or replacements before a problem escalates. Without a uniform high rise strap inspection form template, individual biases or forgetfulness could inadvertently compromise safety.

Furthermore, regulatory compliance is non-negotiable in high-rise operations. Bodies like OSHA mandate regular inspections of fall protection equipment. Having a detailed, completed inspection form serves as undeniable proof of due diligence. It demonstrates that your organization is not only meeting but exceeding safety requirements, providing a transparent record for audits and investigations. This level of documentation protects both the workers and the company in the event of an incident, showcasing a commitment to best practices.

Beyond immediate safety, these forms contribute to the longevity and effective management of your equipment inventory. By meticulously tracking the condition of each strap, you gain valuable insights into its lifecycle. This information helps in making informed decisions about equipment purchasing, rotation, and retirement, optimizing resource allocation while prioritizing safety above all else. It shifts the focus from reactive repair to proactive maintenance, ensuring that equipment is always in optimal condition.

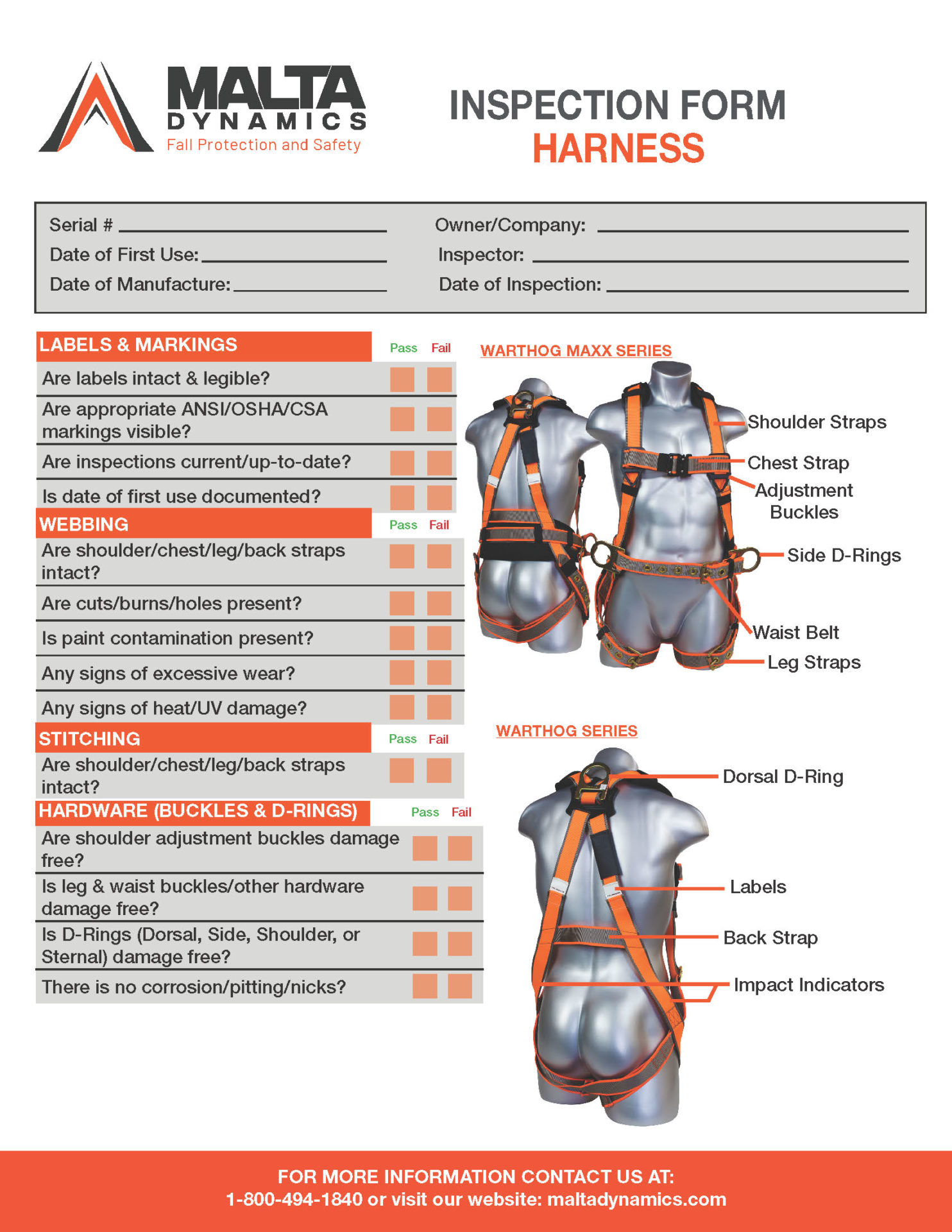

Key Elements to Include

- Date and Time of Inspection

- Unique Strap ID or Serial Number

- Manufacturer, Model, and Date of Manufacture

- Inspector’s Name and Signature

- Specific Condition Checks (e.g., cuts, abrasions, stitching integrity, hardware deformation, chemical exposure)

- Assessment of Pass, Fail, or Repair Required

- Recommended Action and Next Inspection Date

- Any Relevant Notes or Observations

Implementing and Maximizing Your High-Rise Strap Inspection Form Template

Bringing a new inspection template into your workflow requires more than just printing out copies; it demands a structured implementation plan to ensure its effectiveness. The first step involves thoroughly training all personnel who will be conducting these inspections. This training should cover not only how to fill out the form accurately but also, crucially, how to correctly identify various types of damage, wear, and defects on different strap materials and hardware. Understanding what constitutes a “fail” condition is paramount to preventing unsafe equipment from remaining in use.

Consider transitioning from paper forms to a digital solution. Utilizing mobile applications or cloud-based platforms for your inspections can significantly streamline the process. Digital forms allow inspectors to complete checks on-site using a tablet or smartphone, often with integrated photo capture capabilities to document defects. This instantly centralizes data, making it accessible to safety managers, maintenance teams, and project leads from anywhere, at any time. The real-time data flow drastically reduces administrative overhead and accelerates decision-making regarding equipment status.

Regular review of the completed inspection forms is another critical aspect of maximizing their utility. Don’t just file them away. Analyze the data to spot recurring issues, identify straps or brands that wear out faster, or detect patterns related to specific work environments. This analysis can inform future purchasing decisions, refine training programs, and even lead to changes in operational procedures to minimize equipment damage. The insights gained are invaluable for continuous improvement of your safety program.

Finally, remember that safety standards and best practices evolve. Your high-rise strap inspection form template should not be a static document. Schedule periodic reviews of the template itself, perhaps annually or whenever new industry guidelines are released. Gather feedback from inspectors on the ground; they often have valuable insights into what works well and what could be improved. This iterative process ensures that your inspection template remains current, comprehensive, and maximally effective in safeguarding your high-rise workforce.

Maintaining the highest standards of safety in high-rise environments is an ongoing commitment, and meticulous inspection of critical equipment like safety straps is a cornerstone of that endeavor. A well-implemented and regularly utilized inspection form transforms a potential risk into a manageable process, fostering a culture where every team member understands their role in preventing incidents. It’s about being proactive, precise, and systematic in safeguarding lives at height.

Ultimately, the effectiveness of any safety program hinges on its practical application and continuous refinement. By embracing comprehensive inspection protocols facilitated by robust templates, and by leveraging technology for efficiency and data analysis, organizations can not only meet but exceed safety expectations. This commitment ensures that individuals working on towering structures can do so with confidence, knowing that their equipment is thoroughly checked and their well-being is the top priority.