Operating a fleet of heavy equipment means facing the inevitable – breakdowns and maintenance needs. From an excavator sputtering on the job site to a bulldozer needing a transmission overhaul, keeping these powerful machines running smoothly is critical for productivity and profitability. The challenge isn’t just fixing them; it’s managing the entire repair process efficiently, ensuring every detail is captured, and nothing slips through the cracks.

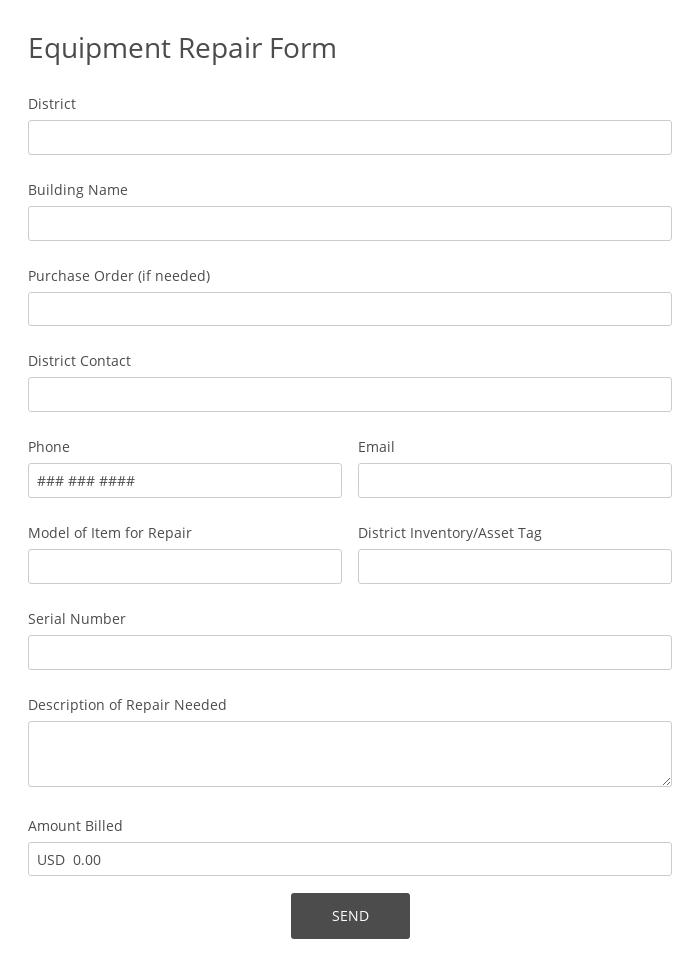

That’s where a well-designed heavy equipment repair form template comes into play. It’s more than just a piece of paper or a digital file; it’s a vital tool for streamlining your maintenance operations, improving communication, and building a comprehensive history for each asset. By standardizing how you report issues, diagnose problems, and document repairs, you can transform a chaotic breakdown into an organized, trackable event.

Why a Dedicated Repair Form is Your Fleet’s Best Friend

Without a structured system, equipment repair can quickly become a headache. Imagine a scenario where a site manager calls in about a faulty hydraulic system, but the details are vague. The technician arrives, unsure what parts to bring, leading to multiple trips and wasted time. Or perhaps a critical repair is performed, but the details aren’t logged, making it impossible to track recurring issues or warranty claims later on. These common frustrations highlight the clear need for a systematic approach.

A specialized heavy equipment repair form template addresses these pain points head-on. It acts as a standardized communication bridge between the operator, the repair technician, and management. By requiring specific information from the outset, it eliminates ambiguity. Everyone knows what details are needed, from the equipment’s unique ID to the specific symptoms observed, ensuring the right information is passed along from the moment an issue arises.

This level of detail isn’t just about immediate repairs; it’s about building a robust historical record. For technicians, having a complete history of previous repairs at their fingertips can significantly aid in quicker and more accurate diagnoses. For management, these forms provide invaluable data for tracking maintenance costs, identifying frequently failing components, and making informed decisions about equipment replacement or upgrades. It transforms reactive repairs into data-driven insights.

Ultimately, a good template saves time, reduces errors, and boosts efficiency across your entire operation. It ensures that every step, from initial problem reporting to final resolution, is documented thoroughly, creating a clear audit trail and facilitating better overall fleet management. But what exactly should such a form include to be truly effective?

Essential Elements of an Effective Heavy Equipment Repair Form Template

-

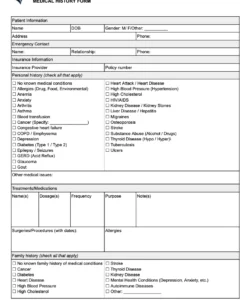

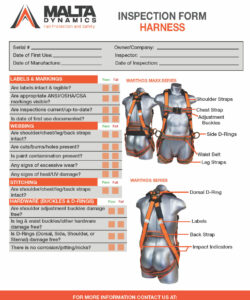

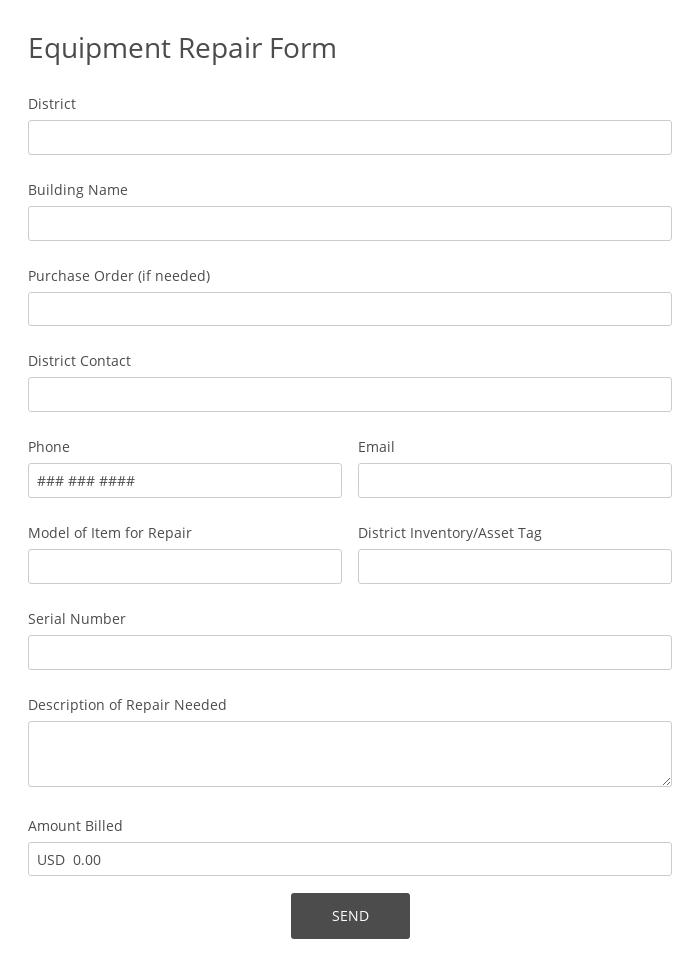

Equipment Details: This section should capture the unique identifier for the machine (e.g., asset tag, VIN), along with its make, model, year, and current hour meter reading. This ensures the repair is accurately linked to the correct piece of equipment.

-

Problem Description: This is where the operator or reporting party details the issue. Encourage descriptive language, including symptoms observed, when the problem started, and any specific noises or behaviors. A clear description helps technicians quickly understand the nature of the fault.

-

Reported By: Information about who reported the issue, their contact details, and the date and time of the report. This allows for follow-up questions if clarification is needed.

-

Repair Details: Once a technician is assigned, this section becomes crucial. It includes the diagnosis of the problem, the root cause, a list of parts used (with part numbers and quantities), labor hours expended, and the name of the performing technician.

-

Resolution and Outcome: A brief summary of the repair work performed, confirmation that the issue has been resolved, and perhaps a note on any tests conducted to verify the fix. Space for a supervisor’s approval or sign-off ensures quality control.

-

Cost Summary: Breaking down the costs associated with the repair, including parts, labor, and any external services. This is vital for budgeting, cost tracking, and calculating the total cost of ownership for each piece of equipment.

Streamlining Your Workflow with a Digital or Printable Template

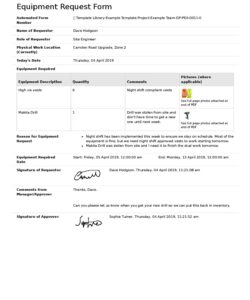

The beauty of a heavy equipment repair form template is its adaptability. Whether you prefer the tactile experience of pen and paper or the seamless integration of digital solutions, a well-designed template can fit into your existing workflow. For many operations, especially those with field service teams, a printable template offers a simple and immediate way to capture information on-site, even in remote locations without internet access. It’s a straightforward method that doesn’t require specialized software or training, allowing for quick deployment across your team.

However, the advantages of a digital heavy equipment repair form template are increasingly compelling. Digital forms can be accessed from tablets or smartphones, allowing technicians to fill them out in real-time, often with features like photo attachments to document damage or completed work. This real-time data entry minimizes errors from manual transcription and ensures information is immediately available to office staff. Digital solutions also facilitate automated workflows, such as sending notifications when a repair is completed or automatically updating inventory for used parts.

Beyond immediate data capture, digital templates unlock powerful analytics. The information collected can be automatically compiled into reports, helping you identify trends in equipment failure, calculate mean time between failures, and forecast future maintenance needs. This move towards data-driven maintenance allows you to shift from a purely reactive approach to a more proactive and even predictive strategy, scheduling maintenance before a breakdown occurs, thereby minimizing downtime and extending equipment lifespan.

Ultimately, whether you choose a physical or digital format, the goal remains the same: to create a consistent, comprehensive record of all maintenance activities. A robust heavy equipment repair form template is more than just a record-keeping tool; it’s a foundational element of a sophisticated fleet management strategy, ensuring your valuable assets are always in peak operating condition and contributing to your bottom line.

Implementing a standardized repair form transforms how you manage your heavy equipment. It shifts the focus from scrambling to fix problems to systematically understanding and preventing them. By ensuring every repair is documented thoroughly, you gain unparalleled visibility into your fleet’s health, allowing for more accurate planning and resource allocation.

This methodical approach not only keeps your equipment running reliably but also optimizes your operational efficiency and safeguards your investment. It’s a simple yet powerful step towards a more organized, cost-effective, and productive heavy equipment operation, paving the way for sustained success.