Navigating the world of Good Manufacturing Practices, or GMP, can feel like a complex journey, especially when it comes to maintaining strict control over every aspect of your operations. One of the cornerstones of ensuring quality and compliance is a robust change control system. This system is crucial for managing any modifications, whether big or small, to facilities, equipment, utilities, processes, or even documentation. Having a well-structured and comprehensive gmp change control form template isn’t just a regulatory requirement; it’s a vital tool that helps you meticulously track and manage every step of a proposed change, ensuring nothing slips through the cracks.

Think of it as your official roadmap for any alteration, guiding you through assessment, approval, implementation, and verification. It’s about maintaining a state of control, ensuring that any change introduced doesn’t negatively impact product quality, safety, or regulatory compliance. A clear, easy-to-use template streamlines this often-detailed process, making it less daunting and more efficient for everyone involved. It helps ensure consistency across all changes, regardless of their nature or the department initiating them, ultimately strengthening your overall quality management system.

Understanding GMP Change Control

GMP change control is essentially a systematic approach to managing all changes made to a system or process within a GMP-regulated environment. This isn’t just about making a change; it’s about evaluating the potential impact of that change before it happens, assessing risks, getting appropriate approvals, implementing it carefully, and then verifying that the change was successful and didn’t introduce new problems. It’s a proactive measure designed to prevent unintended consequences that could compromise the quality, safety, or efficacy of a product. Without a formal change control process, organizations risk introducing issues that could lead to non-compliance, product recalls, or even harm to consumers.

The regulatory landscape, especially in pharmaceuticals, medical devices, and food production, strictly mandates a documented change control process. Agencies like the FDA, EMA, and others expect companies to demonstrate that they have full control over their processes and facilities. This means every modification, no matter how minor it might seem, must be evaluated for its potential impact on validated states, product specifications, and regulatory commitments. It ensures that products consistently meet their intended quality attributes throughout their lifecycle, from development to distribution.

So, what kinds of changes typically fall under this umbrella? It could be anything from upgrading a piece of manufacturing equipment, altering a raw material supplier, modifying a production batch size, updating a standard operating procedure (SOP), or even making a change to a validated computer system. Each of these requires a systematic approach to ensure that the change is carefully considered, planned, executed, and documented. This comprehensive approach minimizes risks and maintains a state of control, which is paramount in any GMP environment.

Key Elements a GMP Change Control Form Template Should Include

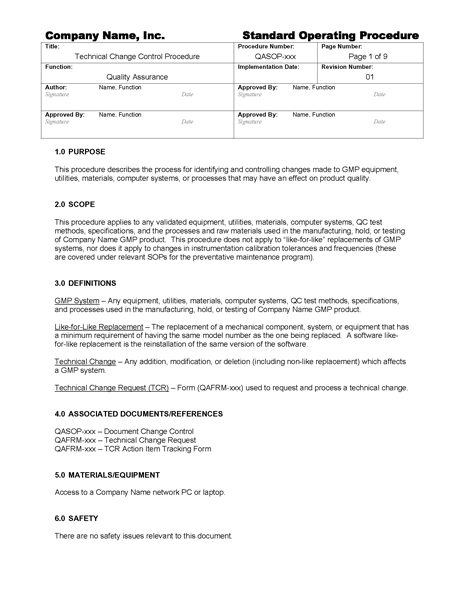

A robust gmp change control form template is the backbone of an effective change management system. It should be designed to capture all necessary information, guide the user through the process, and provide a clear audit trail. Here are some critical elements you would expect to see:

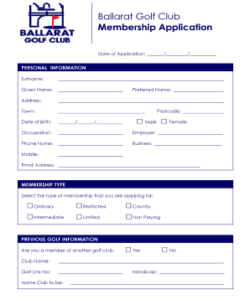

* Change Request Identification: A unique number, date of request, and the initiator’s details.

* Description of Change: A clear, concise explanation of what the proposed change is.

* Reason for Change: Why is this change needed? (e.g., regulatory requirement, quality improvement, efficiency gain).

* Scope and Impact Assessment: What areas, processes, products, or documents will be affected? This is crucial for risk assessment.

* Risk Assessment: Evaluation of potential risks associated with the change and proposed mitigation strategies.

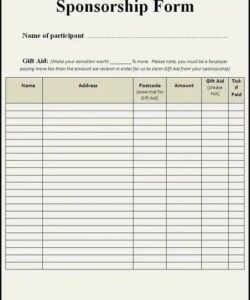

* Required Actions and Responsibilities: Who needs to do what, and by when, for implementation.

* Approval Signatures: Documentation of approvals from relevant stakeholders (e.g., Quality Assurance, Production, Engineering).

* Implementation Plan: Step-by-step instructions for executing the change.

* Verification and Effectiveness Check: How will you confirm the change was successfully implemented and achieved its intended outcome without negative side effects?

* Closure Date and Documentation: Confirmation that the change process is complete and all supporting documentation is filed.

Each of these elements plays a vital role in ensuring that a change is not only properly executed but also thoroughly evaluated for its potential effects on compliance and quality. For example, a detailed impact assessment helps identify all downstream effects, preventing unforeseen issues. The risk assessment ensures that potential problems are identified and mitigated before they become actual issues. Furthermore, clear approval routes ensure that all relevant departments have signed off, providing a collective agreement on the change’s necessity and safety.

Building Your Effective GMP Change Control Form Template

When you set out to create or refine your gmp change control form template, the key is to make it practical and tailored to your organization’s specific needs and size. While there are common elements every template should include, the level of detail and the specific workflow can vary. Start by mapping out your existing change management process, identifying bottlenecks or areas where clarity is lacking. The template should seamlessly integrate into this workflow, guiding personnel through each stage rather than adding complexity. It’s about designing a tool that empowers your team to manage changes effectively, not just fill out paperwork.

Consider involving various departments from the outset. Quality assurance, production, engineering, R&D, and even IT departments often play a role in change control. Their input can be invaluable in designing a template that captures all necessary information from different perspectives and ensures all potential impacts are considered. This collaborative approach helps create a template that is comprehensive, easy to use, and widely adopted throughout the organization. Remember, a template is only as good as its usability and how well it reflects your actual operational realities.

Beyond the fields on the form, think about the associated procedures and training. A template needs clear instructions on how to fill it out, who needs to review it at each stage, and the criteria for approval or rejection. Providing adequate training to all personnel involved in initiating, reviewing, or approving changes will ensure consistency in its application. This proactive approach helps to avoid errors, speed up the review process, and maintain a high level of compliance throughout your operations.

The lifecycle of a change, from its initial idea to its final closure, is greatly facilitated by a well-designed template. It acts as a central repository for all information related to a specific change, making it easy to track progress and audit the process retrospectively.

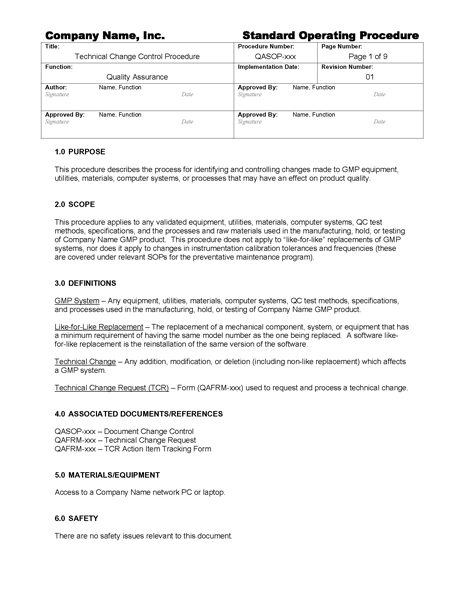

Here are the key steps in the change lifecycle that a template helps facilitate:

* Initiation: Capturing the initial request and its rationale.

* Assessment: Documenting the impact and risk evaluation.

* Approval: Recording the necessary sign-offs from relevant departments.

* Implementation: Guiding the execution of the change according to the plan.

* Verification and Effectiveness Check: Ensuring the change achieved its goal and had no adverse effects.

* Closure: Finalizing the record and archiving documentation.

Ultimately, a well-implemented change control system, supported by a robust template, is not just about meeting regulatory expectations. It’s about fostering a culture of continuous improvement and ensuring that every modification made to your processes or products is thoroughly considered, safely implemented, and carefully documented. This systematic approach contributes significantly to maintaining product quality and patient safety, which are paramount in any regulated industry. It empowers organizations to adapt and evolve while maintaining an unwavering commitment to quality and compliance, ensuring that every step taken is a step towards greater reliability and excellence in production.