In the bustling world of food production, maintaining impeccable quality and efficiency is absolutely paramount. No matter how robust your processes, sometimes things just don’t go exactly to plan. A batch might not meet a specific quality parameter, or perhaps a slight deviation occurred during processing. When these instances arise, simply discarding the product isn’t always the most economical or sustainable solution. This is where the concept of “rework” comes into play: safely and effectively reprocessing a product to bring it up to standard.

However, managing rework isn’t as simple as just throwing product back into the mixer. It requires careful documentation, clear procedures, and a systematic approach to ensure safety, quality, and traceability. Without a structured method, rework can quickly become a source of confusion, inefficiency, and potential quality risks. That’s why having a dedicated food process rework form template isn’t just a good idea; it’s a critical tool for maintaining control and ensuring every product leaving your facility is up to scratch, every single time.

Understanding the Nuances of Food Process Rework

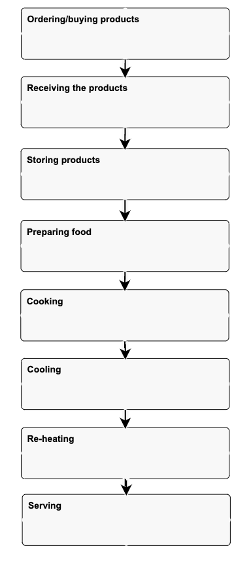

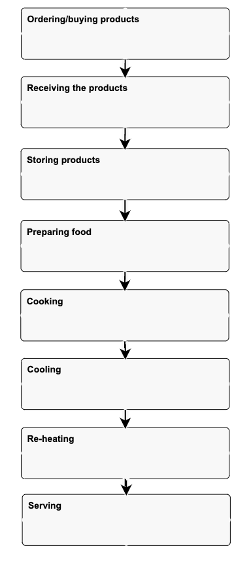

Rework in the food industry refers to the process of taking non-conforming product and reintroducing it into the production stream, or subjecting it to further processing, so that it meets the required specifications. This could range from adjusting a formulation that’s slightly off-spec, to reheating a product that didn’t reach the correct temperature, or even re-packaging items that had damaged outer wrapping. The goal is always to salvage valuable product while upholding the highest standards of food safety and quality.

But why is proper documentation so crucial for this? Imagine a scenario where a batch of biscuits is slightly too moist. Without a formal process, an operator might just add more flour and re-bake without recording the change. This seemingly minor decision could have unforeseen consequences down the line, affecting shelf life, texture, or even allergen control if not properly tracked. Documentation ensures that every step taken during rework is accounted for, providing a clear audit trail and mitigating risks.

Without a structured approach, rework can introduce significant challenges. There’s the risk of cross-contamination if equipment isn’t properly cleaned after handling a non-conforming product. There’s also the danger of creating a product that still doesn’t meet specifications, leading to further waste. Moreover, an undocumented rework process makes it incredibly difficult to identify the root cause of the initial deviation, hindering continuous improvement efforts and potentially allowing recurring issues to persist.

This is precisely where a well-designed food process rework form template becomes indispensable. It acts as a standardized checklist and data capture tool, guiding operators through the necessary steps, ensuring all critical information is recorded, and providing a comprehensive record for quality assurance and regulatory compliance. It transforms an ad-hoc fix into a controlled, auditable process, safeguarding your product and your brand reputation.

Key Elements to Include in Your Rework Form

- Product Identification: Clearly state the product name, batch number, production date, and initial quantity that requires rework.

- Reason for Rework: A detailed description of the non-conformance, including specifications not met, and the deviation observed.

- Rework Procedure: Outline the specific steps taken to reprocess the product, including any additions, temperature adjustments, or processing parameters changed.

- Material Tracking: Document any new ingredients or materials added during rework, including lot numbers and quantities, especially crucial for allergen management.

- Approval Signatures: Sections for the operator, supervisor, and quality assurance personnel to sign off on the rework process, ensuring proper oversight.

- Post-Rework Evaluation: Space to record the results of quality checks performed on the reworked product, confirming it now meets all specifications.

Implementing Your Food Process Rework Form Template for Success

Bringing a new form or process into an existing operation can sometimes be met with resistance, but the long-term benefits of a standardized food process rework form template far outweigh any initial adjustment. By providing a clear, consistent framework, you eliminate guesswork and reduce errors. Your team will know exactly what information to capture and which steps to follow, leading to more efficient and safer rework operations.

To successfully implement your new template, start with a comprehensive training program for all relevant personnel. This includes operators, supervisors, and quality control staff. Explain not just how to fill out the form, but also the “why” behind each section. Help them understand how accurate documentation protects product quality, ensures food safety, and contributes to the overall efficiency and profitability of the production line. A well-informed team is a compliant team.

Consistency is key. Encourage regular use of the template for every rework scenario, no matter how small. Initially, it might feel like an extra step, but over time, it will become an integral part of your standard operating procedures. Consider incorporating the completion of the rework form into your quality checks and internal audits to reinforce its importance and ensure compliance.

Finally, don’t view your food process rework form template as a static document. It should be a living tool that evolves with your processes and products. Regularly review the completed forms to identify trends in non-conformances, assess the effectiveness of your rework procedures, and pinpoint areas for improvement in your primary production processes. This continuous feedback loop is invaluable for driving sustained quality and operational excellence.

- Standardization: Ensures all rework is handled consistently, reducing variability and risk.

- Traceability: Provides a clear, documented history of every rework batch, critical for audits and investigations.

- Root Cause Analysis: Data collected can help identify recurring issues, leading to process improvements and reduced future rework.

Embracing a systematic approach to handling non-conforming products through a well-designed template helps transform potential losses into valuable insights. It’s about more than just salvaging product; it’s about refining your entire production chain, enhancing food safety, and building greater confidence in your outputs.

Ultimately, investing time in developing and implementing such a critical document contributes significantly to a more resilient, efficient, and quality-driven food manufacturing operation. It’s a proactive step towards excellence that benefits everyone, from the production floor to the consumer’s table.