Utilizing a structured approach to electrical tasks significantly reduces workplace incidents and promotes a safer environment. Clear communication of hazards and precautions minimizes the likelihood of errors and injuries. This proactive approach also aids in compliance with safety regulations and can reduce liability. Furthermore, consistent application of standardized procedures improves overall efficiency and productivity.

The following sections delve deeper into the core components of effective procedures for electrical work, covering hazard identification, risk assessment, and the development of robust control measures. Practical examples and detailed explanations will provide a comprehensive understanding of how to implement these crucial safety practices.

1. Hazard Identification

Hazard identification forms the cornerstone of an effective electrical safe work method statement. Without a clear understanding of potential dangers, subsequent steps like risk assessment and control measures become ineffective. This process involves systematically examining the work environment and the specific tasks involved to identify all foreseeable electrical hazards. Examples include exposed live conductors, overhead power lines, faulty equipment, inadequate lighting, and potential for arc flash or electric shock. A comprehensive hazard identification process considers not only the obvious risks but also less apparent dangers like potential for induced currents or the presence of flammable materials that could ignite in the event of an electrical fault.

The accuracy and thoroughness of hazard identification directly impact the overall safety of the electrical work. Overlooking a potential hazard can have serious consequences, leading to accidents, injuries, or even fatalities. For instance, failing to identify the presence of underground cables before excavation work could result in a cable strike, causing electrocution and potential damage to essential services. Similarly, neglecting to account for the risk of arc flash during switchgear maintenance can lead to severe burns and injuries. By meticulously identifying all potential hazards, a robust foundation is established for the subsequent development of appropriate control measures within the safe work method statement.

Effective hazard identification requires a combination of experience, knowledge of electrical systems, and the use of appropriate tools and techniques. Checklists, site surveys, and consultations with experienced personnel contribute to a comprehensive understanding of potential risks. Integrating this understanding into the safe work method statement ensures that all foreseeable hazards are addressed, contributing to a safer work environment and minimizing the likelihood of incidents. This proactive approach not only protects workers but also safeguards equipment and ensures operational continuity.

2. Risk Assessment

Risk assessment is a critical component of an electrical safe work method statement. It builds upon hazard identification by analyzing the potential severity of each identified hazard and the likelihood of its occurrence. This process allows for prioritization of control measures, focusing resources on the most significant risks. A thorough risk assessment is essential for creating a safe work environment and minimizing the potential for incidents.

- Severity of HarmThis facet evaluates the potential consequences of an incident. For electrical hazards, this could range from minor shocks to fatalities. For example, working near exposed high-voltage conductors carries a higher potential for severe injury or death than working with low-voltage circuits. Accurately assessing the potential severity informs the selection of appropriate safety measures. A higher potential severity necessitates more stringent controls.

- Likelihood of OccurrenceThis element considers the probability of a hazard leading to an incident. Factors such as the frequency of exposure, the working environment, and the competence of personnel are considered. Working in wet conditions increases the likelihood of electric shock. Infrequent tasks might require refresher training to reduce the probability of errors. Understanding the likelihood of occurrence allows for proportionate control measures. Frequent exposure to high-risk hazards necessitates more robust controls than infrequent exposure to low-risk hazards.

- Risk MatrixA risk matrix combines the severity and likelihood of each hazard to determine an overall risk level. This visual tool provides a clear representation of the risks associated with the electrical work. It aids in prioritizing control measures and allocating resources effectively. High-risk activities require more comprehensive controls than low-risk activities. The matrix helps visualize and prioritize safety efforts.

- DocumentationDocumenting the risk assessment process provides a record of the hazards identified, their associated risks, and the chosen control measures. This documentation becomes an integral part of the safe work method statement, ensuring transparency and accountability. It also serves as a valuable resource for future projects and training. Clear documentation facilitates communication and continuous improvement of safety procedures.

Effective risk assessment allows for informed decision-making regarding safety precautions and control measures, ensuring that the safe work method statement adequately addresses the specific hazards associated with the electrical work. By systematically evaluating and documenting risks, a proactive approach to safety is fostered, minimizing the potential for incidents and creating a safer work environment. This systematic approach forms an integral part of a robust electrical safety management system.

3. Control Measures

Control measures are the practical actions implemented to mitigate the risks identified in the risk assessment process. Within an electrical safe work method statement, these measures form the core of the safety strategy, outlining specific procedures and precautions to ensure worker safety and prevent incidents. Effective control measures directly address the hazards associated with electrical work, providing a systematic approach to risk reduction.

- Isolation ProceduresIsolation procedures are fundamental to electrical safety. They involve de-energizing electrical equipment and circuits before work commences, eliminating the risk of electric shock. Lockout/tagout procedures ensure equipment remains isolated throughout the work process. Clear protocols for verifying isolation, such as testing for the absence of voltage, are crucial. For instance, before working on a distribution panel, a qualified electrician must follow a specific lockout/tagout procedure to isolate the panel and prevent accidental re-energization.

- Personal Protective Equipment (PPE)PPE provides an additional layer of protection against electrical hazards. Insulated gloves, arc-flash suits, and safety footwear protect workers from electric shock, burns, and other injuries. Selecting appropriate PPE depends on the specific hazards identified in the risk assessment. Working with high-voltage equipment necessitates higher levels of protection than working with low-voltage circuits. Regular inspection and maintenance of PPE are essential to ensure its effectiveness.

- Safe Work PracticesSafe work practices encompass a range of procedures designed to minimize risk during electrical work. These practices include using insulated tools, maintaining safe distances from energized equipment, and ensuring proper grounding and bonding. For example, when working near overhead power lines, maintaining a safe clearance distance is critical to prevent accidental contact. Adhering to established safe work practices forms a crucial part of the safe work method statement.

- Emergency ProceduresDespite implementing control measures, emergencies can still occur. A safe work method statement must include clear emergency procedures outlining steps to be taken in the event of an incident, such as electric shock, fire, or explosion. These procedures should include contact information for emergency services, first aid procedures, and evacuation plans. Regular drills and training ensure personnel are familiar with these procedures, facilitating a rapid and effective response in an emergency.

These control measures, when integrated into a comprehensive electrical safe work method statement, create a robust safety framework. This framework ensures that electrical work is carried out in a controlled and predictable manner, minimizing the potential for incidents. By systematically addressing identified hazards, implementing appropriate safety procedures, and establishing clear emergency protocols, the safe work method statement fosters a culture of safety and protects workers from the inherent risks associated with electrical work. The effectiveness of these control measures relies on consistent implementation and regular review to adapt to changing work conditions and evolving best practices.

4. Emergency Procedures

Emergency procedures are a critical component of an electrical safe work method statement template. A well-defined emergency response plan bridges the gap between incident occurrence and effective mitigation, minimizing potential harm. Electrical work, inherently hazardous, necessitates pre-planned responses to various scenarios, including electric shock, arc flash/blast, fire, and equipment malfunction. Without pre-determined procedures, responses can be delayed, disorganized, and ineffective, exacerbating the consequences of an incident.

Consider a scenario where an electrician experiences an electric shock while working on a live circuit. A comprehensive emergency procedure within the safe work method statement would dictate immediate actions: cutting off the power supply, administering first aid, and contacting emergency medical services. The method statement should also detail the location of emergency equipment, such as first-aid kits and fire extinguishers, and assign responsibilities to specific personnel. This structured approach ensures a swift, coordinated response, potentially saving lives and minimizing the severity of injuries. Conversely, the absence of clear procedures could lead to confusion and delays, increasing the risk of further harm.

Practical application of this understanding involves regular drills and training for all personnel involved in electrical work. Simulating emergency scenarios allows workers to practice the procedures outlined in the safe work method statement, ensuring familiarity and promoting a rapid, effective response under pressure. Regular review and updates of emergency procedures are essential to adapt to evolving work environments and incorporate lessons learned from past incidents or near misses. This iterative process reinforces a culture of preparedness and continuous improvement in electrical safety management, ultimately minimizing the impact of unforeseen events. This meticulous planning underscores the vital role of emergency procedures within a comprehensive safe work method statement, transforming potential chaos into controlled response.

5. Competent Personnel

Competent personnel are integral to the effectiveness of an electrical safe work method statement template. The template provides the framework for safe electrical work, but its successful implementation relies heavily on the skills, knowledge, and experience of those carrying out the tasks. A comprehensive method statement is rendered useless without qualified individuals capable of interpreting and applying its provisions correctly. This underscores the critical link between a well-defined procedure and the individuals entrusted with its execution. Without competent personnel, even the most meticulously crafted safe work method statement cannot guarantee safety.

Consider a scenario involving complex lockout/tagout procedures for high-voltage equipment. A safe work method statement may detail the necessary steps, but only a trained and authorized electrician possesses the expertise to execute these procedures safely and effectively. An unqualified individual attempting the same task, despite having access to the method statement, risks serious injury or equipment damage due to a lack of understanding or practical experience. This example highlights the crucial role of competence in translating theoretical procedures into safe practice. It emphasizes that a safe work method statement is not a substitute for skilled personnel, but rather a tool that amplifies their effectiveness in maintaining a safe working environment.

Practical implications of this understanding include rigorous training programs, regular competency assessments, and continuous professional development for electrical workers. Employers bear the responsibility of ensuring their personnel possess the necessary qualifications and experience to perform electrical tasks safely. This involves not only initial training but also ongoing updates and refreshers to keep pace with evolving safety standards and best practices. Furthermore, fostering a culture of safety within the organization encourages workers to identify and report potential hazards, contributing to a more robust and effective implementation of the electrical safe work method statement. This proactive approach, combining a comprehensive template with competent personnel, establishes a strong safety foundation, minimizing risks and promoting a secure work environment for all involved in electrical operations.

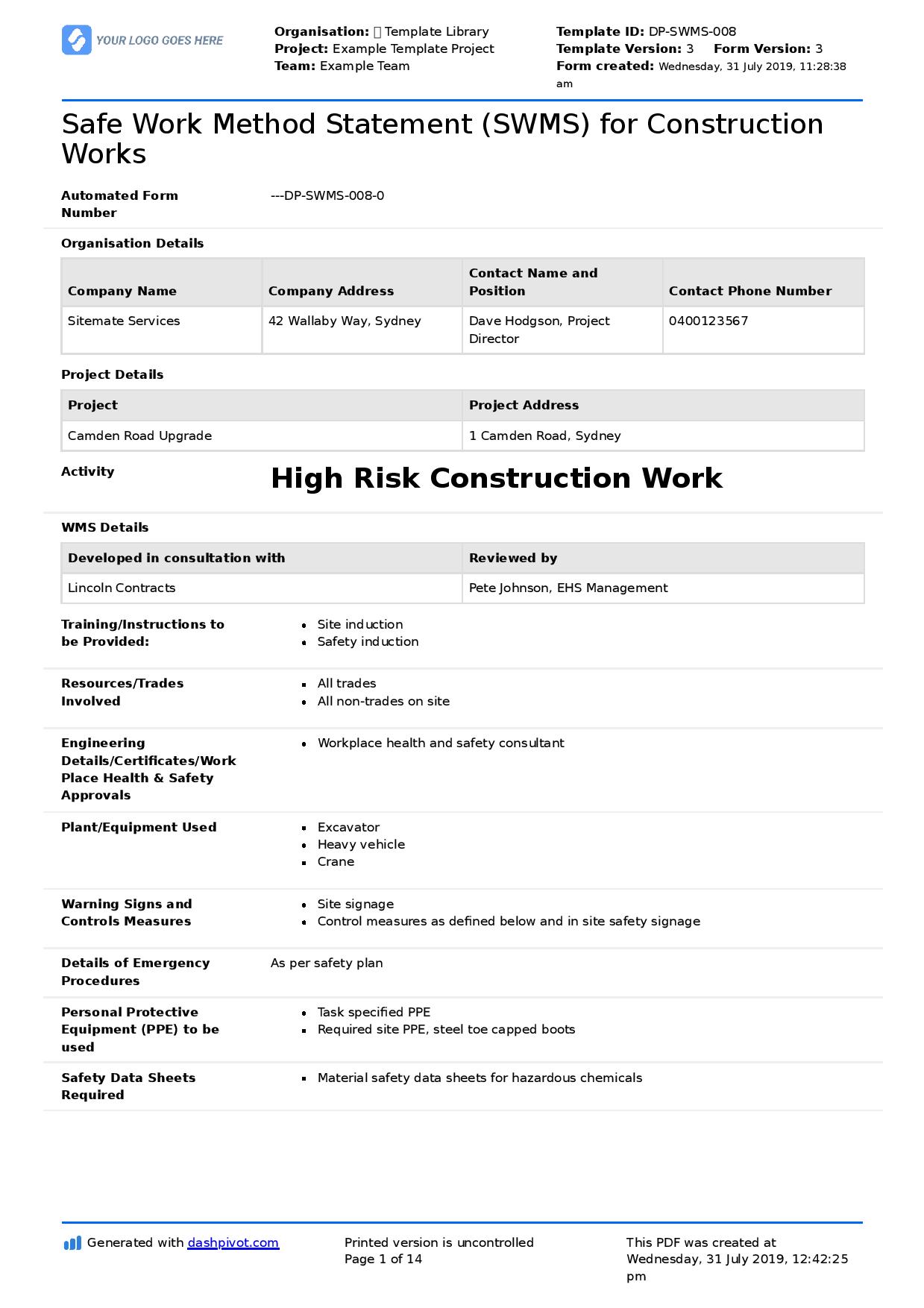

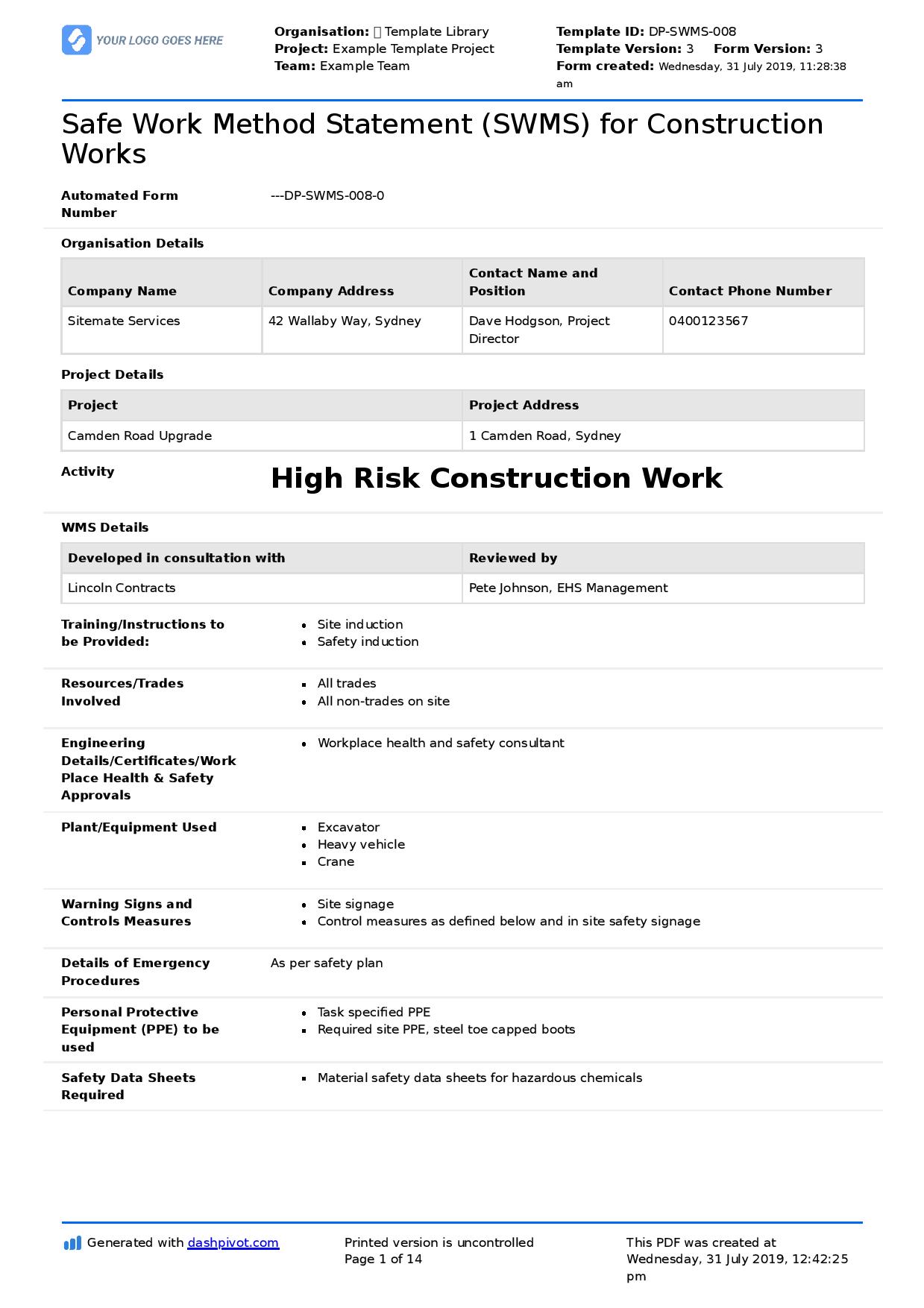

Key Components of an Electrical Safe Work Method Statement

A comprehensive electrical safe work method statement requires several key components to ensure worker safety and prevent incidents. These components work together to provide a structured approach to identifying, assessing, and mitigating electrical hazards. Omitting any of these elements can compromise the effectiveness of the entire safety plan.

1. Scope of Work: Clearly defines the boundaries of the electrical work, including specific tasks, locations, and equipment involved. This ensures the method statement addresses all relevant hazards within the defined scope.

2. Hazard Identification: Systematically identifies all foreseeable electrical hazards associated with the defined scope of work. This includes potential risks from energized equipment, overhead power lines, faulty wiring, and environmental factors.

3. Risk Assessment: Evaluates the likelihood and potential severity of each identified hazard. This process allows for prioritization of control measures, focusing resources on the most significant risks.

4. Control Measures: Outlines specific procedures and precautions to mitigate the identified risks. These measures may include isolation procedures, lockout/tagout systems, use of personal protective equipment (PPE), and safe work practices.

5. Emergency Procedures: Details the steps to be taken in the event of an electrical incident, such as electric shock, arc flash, or fire. Includes contact information for emergency services, first aid procedures, and evacuation plans.

6. Competent Personnel: Specifies the qualifications, training, and experience required for personnel involved in the electrical work. This ensures tasks are performed by individuals with the necessary skills and knowledge to execute the method statement effectively.

7. Documentation and Communication: Emphasizes the importance of documenting the entire process, including hazard identification, risk assessment, and control measures. This documentation provides a record of the safety plan and facilitates communication among all stakeholders.

8. Review and Revision: Highlights the need for regular review and revision of the method statement to ensure its ongoing effectiveness. This includes incorporating lessons learned from incidents, near misses, and changes in work practices or regulations.

A robust method statement ensures electrical work is performed safely and efficiently. Each component contributes to a comprehensive safety framework that protects workers, minimizes risks, and promotes a secure work environment. Regular review and adaptation of the method statement maintain its relevance and effectiveness in dynamic work environments.

How to Create an Electrical Safe Work Method Statement Template

Creating a robust template ensures consistent application of safety procedures across various electrical tasks. A systematic approach facilitates thorough consideration of potential hazards and implementation of effective control measures. The following steps outline the process of developing a comprehensive template.

1. Define the Scope: Clearly delineate the specific electrical work activities covered by the template. This includes the type of work, location, equipment involved, and potential interactions with other trades or activities. A precise scope ensures the template’s relevance and applicability.

2. Identify Hazards: Conduct a thorough hazard identification process, considering all potential sources of electrical risk. This includes exposed live conductors, overhead power lines, faulty equipment, inadequate lighting, and potential for arc flash or electric shock. Consult regulations, industry standards, and experienced personnel to ensure comprehensiveness.

3. Assess Risks: Evaluate the likelihood and potential severity of each identified hazard. Employ a risk matrix to categorize risks based on their potential impact and probability of occurrence. This facilitates prioritization of control measures.

4. Develop Control Measures: Implement appropriate control measures to mitigate identified risks. Prioritize elimination or substitution of hazards where feasible. Engineering controls, such as isolation procedures and guarding, should be prioritized over administrative controls and PPE. Ensure control measures are practical, enforceable, and readily accessible to workers.

5. Establish Emergency Procedures: Outline clear emergency procedures for various scenarios, including electric shock, fire, and equipment malfunction. Specify contact information for emergency services, first aid procedures, and evacuation plans. Conduct regular drills to ensure personnel familiarity and preparedness.

6. Define Competency Requirements: Specify the required qualifications, training, and experience for personnel involved in electrical work. Ensure personnel possess the necessary certifications and authorizations to perform designated tasks. Implement regular competency assessments and refresher training to maintain proficiency.

7. Document and Communicate: Document the complete template, including the scope of work, hazard identification, risk assessment, control measures, and emergency procedures. Communicate the template to all relevant personnel and ensure it is readily accessible. Provide training on the template’s application and ensure comprehension.

8. Review and Revise: Establish a system for regular review and revision of the template. Incorporate lessons learned from incidents, near misses, and changes in work practices, regulations, or industry standards. This iterative process ensures the template remains current and effective in mitigating evolving electrical hazards.

A well-structured template guides safe execution of electrical tasks, minimizing risks and ensuring compliance with regulations. Regular review and adaptation maintain its effectiveness. Consistent application of the template fosters a robust safety culture within the organization. This contributes to a safer work environment and reduces the likelihood of incidents.

Documented procedures for electrical work, facilitated by pre-designed templates, provide a crucial framework for mitigating inherent risks. A systematic approach to hazard identification, risk assessment, and implementation of robust control measures ensures personnel safety and operational efficiency. Emergency preparedness, through well-defined procedures and personnel training, further strengthens the safety net, reducing the potential impact of unforeseen incidents. Competency of personnel, underpinned by appropriate qualifications and ongoing training, forms the cornerstone of effective implementation, translating procedural guidelines into practical, safe actions. This integrated approach, combining structured documentation with skilled execution, forms a robust defense against electrical hazards.

Prioritizing electrical safety through meticulous planning and consistent application of these principles is not merely a regulatory requirement but a fundamental responsibility. Continual refinement of safety procedures, informed by industry best practices and lessons learned, fosters a culture of proactive risk management. This commitment to safety safeguards both personnel and infrastructure, ensuring sustainable and secure operations in the electrical sector.