Managing company assets, especially equipment that frequently moves in and out of storage, can be a real headache. Whether you’re running a construction company with tools on various sites, a production studio with cameras constantly being checked out, or an IT department lending laptops, keeping track of every single item is crucial. Without a clear system, valuable assets can get lost, damaged, or simply go missing, leading to unexpected costs and operational delays. It’s not just about knowing where something is; it’s about accountability, maintenance tracking, and ensuring your team always has the right tools for the job.

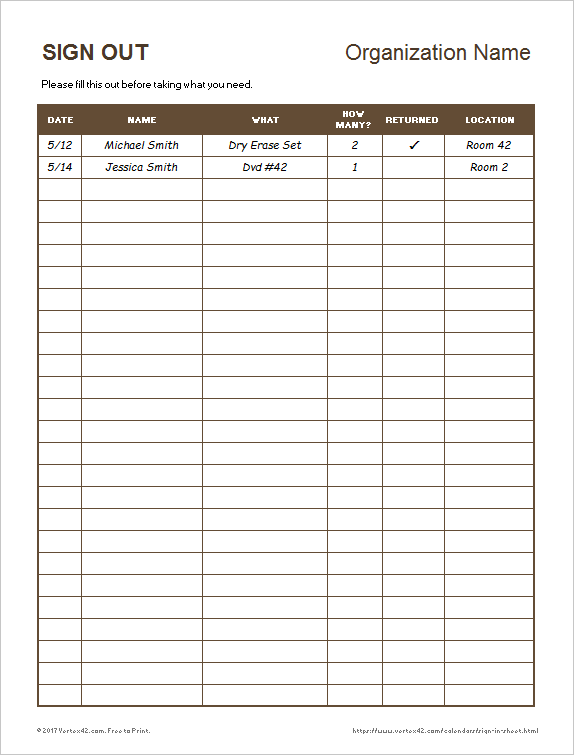

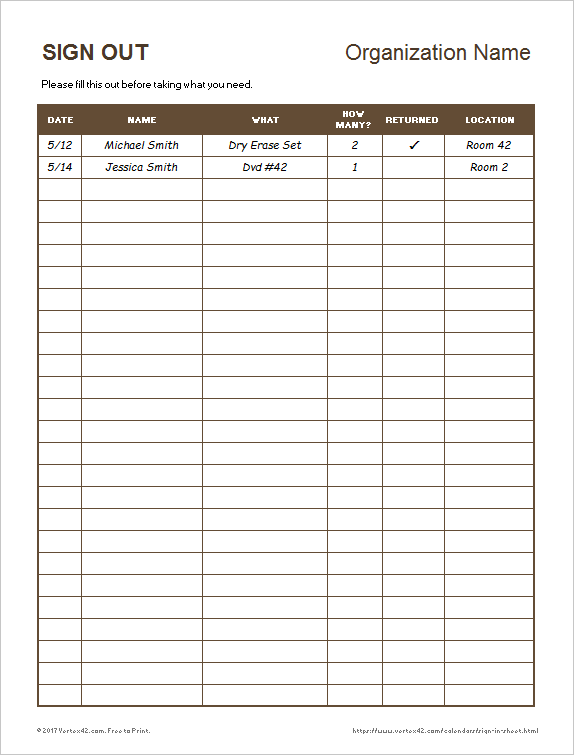

That’s where a well-designed equipment pull out form template comes in. This simple yet powerful tool can transform how you manage your inventory, bringing order to what might feel like chaos. It provides a standardized process for documenting every piece of equipment leaving its designated storage, who is taking it, for what purpose, and when it’s expected back. Think of it as your dependable co-pilot in asset management, helping you maintain a clear overview of your valuable resources, reduce losses, and even streamline maintenance schedules. Let’s explore why having such a template is not just a good idea, but an essential component for any organization dealing with physical assets.

The Indispensable Role of a Structured Equipment Tracking System

In any business that relies on physical assets, a robust tracking system isn’t a luxury; it’s a necessity. Imagine the frustration of needing a specific piece of equipment, only to find it’s nowhere to be found, and nobody knows who had it last. This scenario is all too common in environments without a clear “check-out” procedure. A structured system, particularly one built around an effective equipment pull out form template, helps prevent these costly situations by ensuring every movement of equipment is recorded and attributed.

Beyond simply locating items, a proper tracking system provides invaluable insights into asset utilization. Are certain pieces of equipment constantly in demand, suggesting you might need more? Or are others rarely used, perhaps indicating they’re obsolete or overstocked? This data can inform future purchasing decisions, helping you optimize your investment in equipment. It also fosters a culture of accountability among your team, as everyone knows that equipment usage is being documented.

Moreover, consistent tracking is vital for maintenance and compliance. By knowing exactly which equipment has been used and for how long, you can proactively schedule servicing, repairs, and calibration. This not only extends the lifespan of your assets but also ensures they meet safety standards and perform optimally, reducing the risk of breakdowns during critical operations. For regulated industries, meticulous records are often a legal requirement, making a structured pull-out process indispensable.

Ultimately, implementing a reliable system for tracking equipment pull-outs translates directly into operational efficiency and cost savings. It minimizes downtime caused by missing or malfunctioning tools, reduces the need for emergency replacements, and helps you make informed decisions about your inventory. It’s about building a predictable and organized environment where your assets work for you, not against you.

Key Elements for Your Equipment Pull Out Form

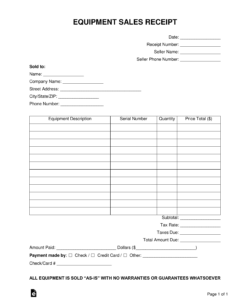

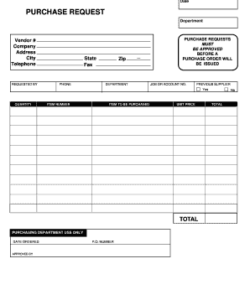

- Requestor Information: Name, department, contact details, date of request.

- Equipment Details: Item name, asset tag/serial number, description, quantity.

- Purpose of Use: Project name, job number, specific task for which the equipment is needed.

- Expected Return Date: A clear deadline for when the equipment should be brought back.

- Authorization: Signature lines for the requestor and the approving authority.

- Condition Notes: Space to record the equipment’s condition when it leaves and returns.

Crafting the Perfect Equipment Pull Out Form for Your Operations

While the core purpose of an equipment pull out form template remains consistent across industries, the specifics of your template should be tailored to your unique operational needs. No two businesses are exactly alike, and neither should their forms be. Consider the types of equipment you manage, the frequency of check-outs, the size of your team, and any specific regulatory requirements you might face. A template for heavy machinery on a construction site will look different from one for audio-visual gear in a school, though both share the fundamental goal of tracking.

When you’re designing or customizing your form, think about user-friendliness. Will your team find it easy to fill out quickly and accurately? Cluttered or overly complicated forms often lead to errors or, worse, abandonment. Prioritize clarity, logical flow, and sufficient space for all necessary information. You might opt for a digital solution, like a spreadsheet or a dedicated asset management software, which can offer automation features, reporting capabilities, and easier data retrieval compared to paper forms.

Incorporating unique identifiers for your equipment, such as QR codes or barcodes, can significantly enhance the efficiency of your pull-out process. When linked to your tracking system, a quick scan can automatically populate equipment details, reducing manual entry and the potential for human error. This level of integration transforms a simple form into a dynamic part of a comprehensive asset management strategy, making it easier to track lifecycle events from acquisition to disposal.

Remember, the form itself is just one piece of the puzzle. Effective implementation also involves clear policies, consistent enforcement, and regular training for your team. Ensure everyone understands the importance of the process and how to properly complete the form. Regularly review the effectiveness of your template and make adjustments as your business evolves, ensuring it remains a valuable tool for maintaining oversight and control over your valuable assets.

Embracing a systematic approach to asset management, anchored by a robust equipment check-out process, can profoundly impact your operational efficiency and bottom line. It’s about moving from reactive problem-solving to proactive management, ensuring your resources are always optimized and accounted for. This shift not only prevents losses but also empowers your team with the tools they need, precisely when they need them, fostering a more productive and organized work environment.

By investing time into creating and implementing a streamlined procedure for managing your valuable assets, you’re not just tracking items; you’re building a foundation for greater accountability, improved resource allocation, and sustained operational excellence. It’s a proactive step that protects your investments and supports the seamless flow of your daily operations, ultimately contributing to your organization’s long-term success and peace of mind.