In any organization that relies on machinery, tools, or vehicles, the smooth operation of equipment is absolutely critical. When something breaks down or needs routine maintenance, getting it fixed efficiently can be the difference between minor inconvenience and significant operational disruption. Without a clear, standardized way to report issues, you often face delays, miscommunication, and a chaotic scramble to identify what’s wrong and who’s responsible.

This is where an equipment service request form template comes into play. It’s not just a piece of paper or a digital document; it’s a vital tool designed to streamline the entire maintenance process from the moment an issue is identified. By providing a structured format for reporting problems, requesting service, and tracking progress, these templates ensure that critical information is captured consistently, leading to faster resolutions and improved overall efficiency.

Why a Dedicated Equipment Service Request Form Template is Crucial for Efficiency

Think about a busy workday. A critical piece of machinery starts making an unusual noise, or a vehicle won’t start. Without a formal process, an employee might send an email, make a phone call, or even just tell someone in passing. This unstructured approach often leads to vital details being missed: Was it just a noise, or was smoke involved? What’s the exact model number of the equipment? Where is it located? Who noticed the issue? All these questions, if unanswered, create delays and extra work for the maintenance team, who then have to chase down information.

Implementing a standardized equipment service request form template combats this chaos directly. It ensures that every service request starts with a comprehensive set of information. This clarity significantly reduces back-and-forth communication, allowing your maintenance staff to understand the problem fully before even stepping foot on the scene. They can arrive prepared with the right tools, parts, and a clear understanding of the issue, saving valuable time and reducing downtime.

Furthermore, a consistent template helps in tracking and analyzing maintenance trends. When all requests follow the same format, it becomes much easier to log them into a system, categorize them, and run reports. You can identify which pieces of equipment break down most frequently, what types of issues are common, and how long typical repairs take. This data is invaluable for proactive maintenance planning, budgeting for replacements, and improving the longevity of your assets.

Essential Elements of an Effective Template

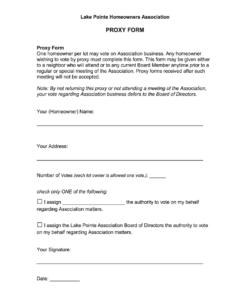

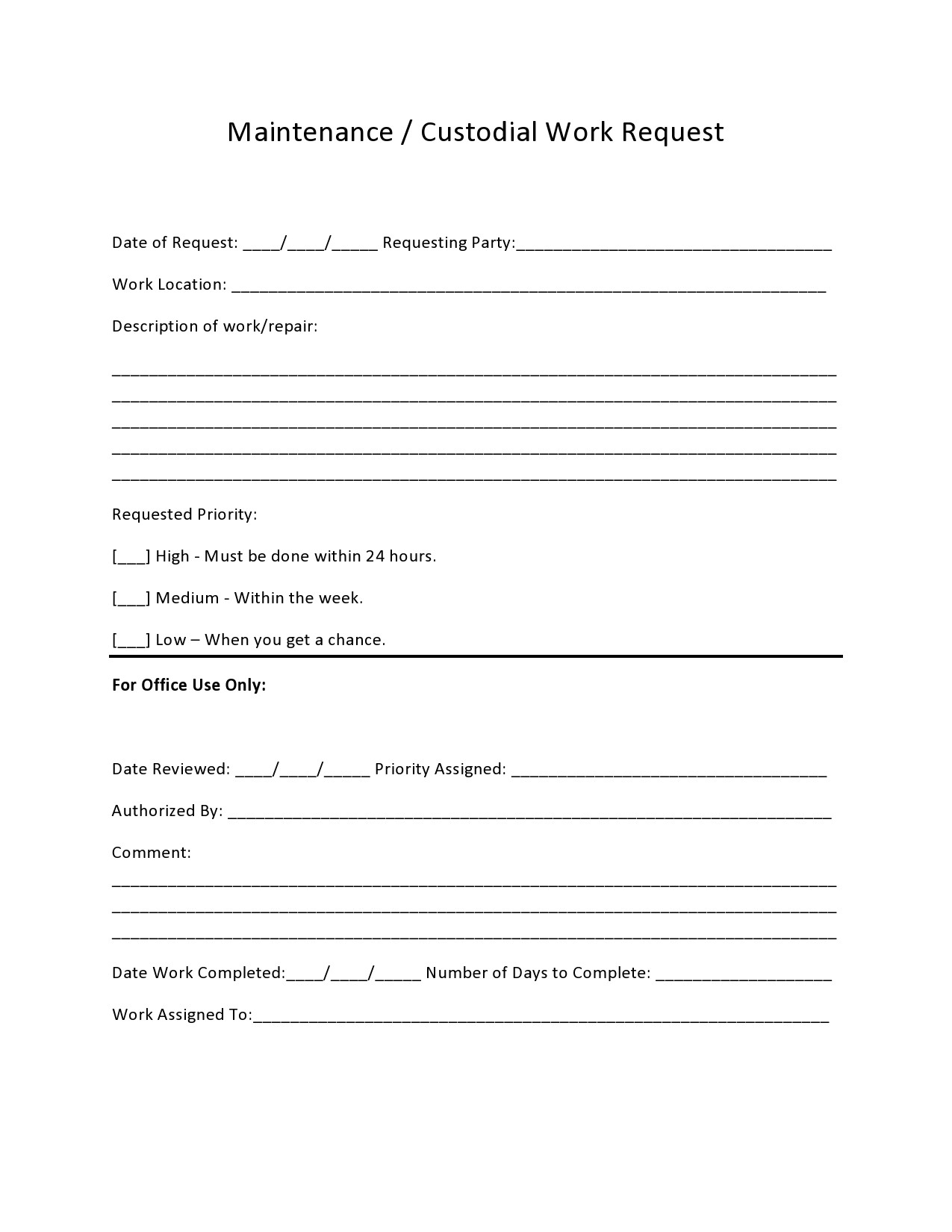

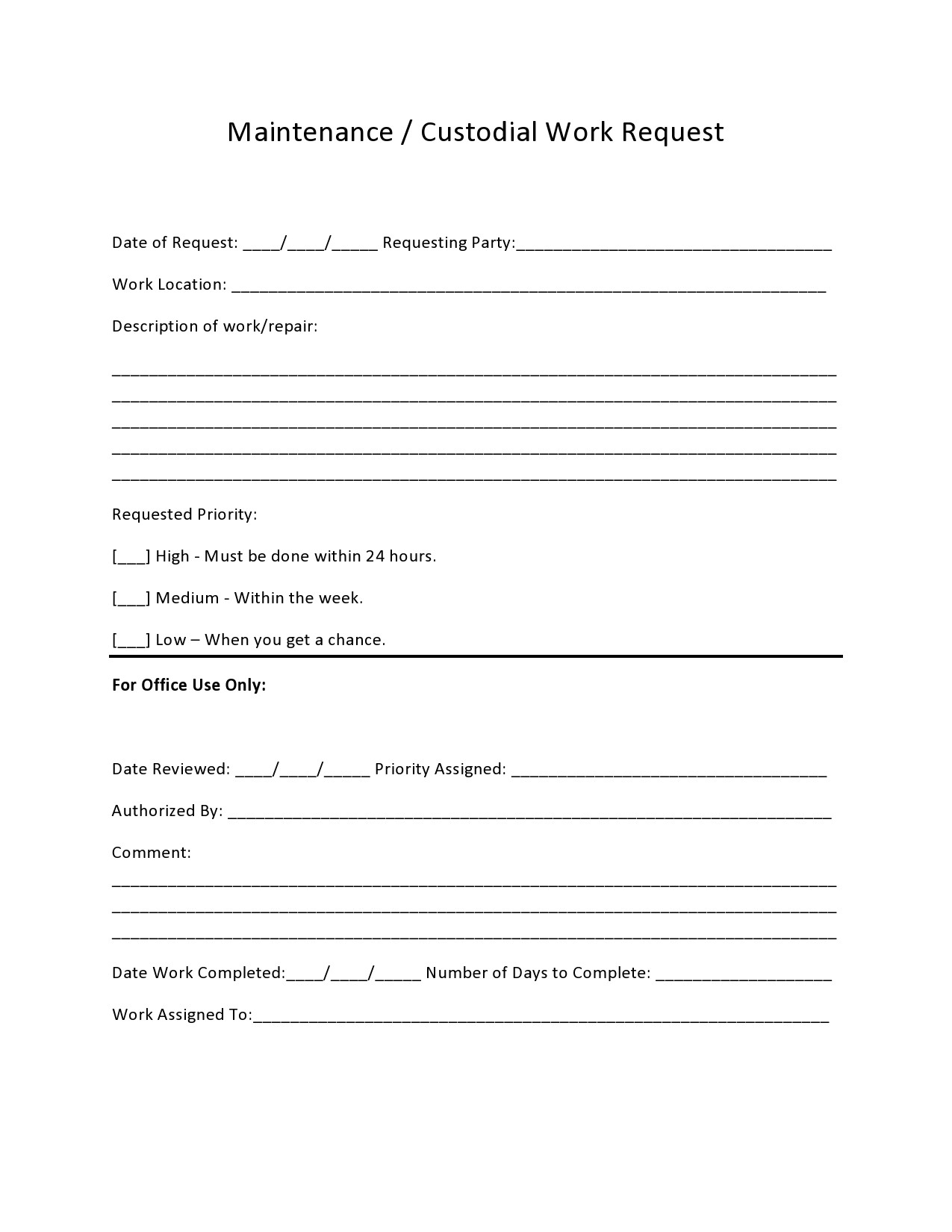

To truly maximize the benefits, your template needs to capture specific, critical pieces of information. A well-designed equipment service request form template should include:

-

Requester Information: Name, department, contact details (phone, email). This ensures the maintenance team knows who to follow up with for more details or to confirm completion.

-

Equipment Identification: Specific details like asset ID number, equipment type (e.g., HVAC unit, forklift, printer), make, model, and physical location within your facility. This prevents confusion and ensures the right equipment is addressed.

-

Problem Description: A detailed, clear explanation of the issue. Encourage users to provide specific observations (e.g., “grinding noise from left side,” “paper jam in tray 2,” “engine sputtering and dying”). Include when the problem started and any error codes displayed.

-

Urgency Level: A field to indicate the priority of the request (e.g., critical, high, medium, low). This helps the maintenance team prioritize their workload and respond appropriately based on the impact on operations.

-

Requested Completion Date: If applicable, a desired date for service completion, giving the maintenance team a target to work towards.

-

Authorization/Approval: Space for a supervisor or manager to sign off on the request, particularly for high-cost repairs or non-emergency maintenance.

Practical Steps for Implementing Your Equipment Service Request Form Template for Success

Once you’ve designed your perfect equipment service request form template, the next step is to ensure it’s effectively implemented and adopted across your organization. Start by choosing the right format. While paper forms might seem simpler initially, digital forms, whether through a dedicated CMMS (Computerized Maintenance Management System), an internal shared drive, or even a simple online form builder, offer significant advantages. Digital forms can include mandatory fields, enable automated routing to the right department, and make data tracking and reporting infinitely easier than manually sorting through paper.

Clarity and accessibility are paramount. Your template should be intuitive and straightforward for anyone to fill out, regardless of their technical expertise. Use clear language, provide specific instructions where necessary, and ensure it’s easily accessible to all employees who might need to submit a request. This could mean pinning it to a common notice board, linking it prominently on your intranet, or integrating it directly into your company’s existing communication channels.

Training and communication are also vital for successful adoption. Don’t just introduce the new form and expect everyone to use it. Conduct brief training sessions for relevant departments, explaining why the new template is being implemented, its benefits, and how to fill it out correctly. Emphasize that using the form benefits everyone by leading to quicker, more efficient service. Providing a brief “how-to” guide or a simple FAQ document can also be incredibly helpful for employees.

Finally, remember that implementation is an ongoing process. Encourage feedback from employees using the form and from your maintenance team processing the requests. Are there any fields that are consistently confusing? Is essential information frequently missing? Be prepared to iterate and refine your template based on real-world usage. A successful equipment service request form isn’t a static document; it evolves with your organization’s needs, ensuring continuous improvement in your maintenance operations and asset management.

Adopting a structured approach to maintenance requests can fundamentally transform how your organization manages its assets. By standardizing the information captured at the very beginning of a service incident, you empower your maintenance team to act swiftly and effectively, minimizing downtime and extending the lifespan of valuable equipment. It’s a proactive step that pays dividends in operational efficiency and cost savings.

Investing time in creating and implementing a robust equipment service request system, anchored by a well-designed template, is a strategic move for any business. It fosters better communication, enables data-driven decisions, and ultimately contributes to a more reliable and productive operational environment for everyone involved.