Working at heights always comes with inherent risks, and ensuring the safety of workers is paramount. It’s not just about compliance with regulations; it’s about protecting lives and fostering a culture where everyone returns home safely at the end of the day. A crucial component of any robust safety program involving elevated work is the diligent inspection of fall protection equipment. This isn’t a task to be taken lightly, as the integrity of harnesses, lanyards, anchor points, and other gear directly impacts a worker’s well-being.

Regular, documented inspections are the cornerstone of effective fall protection. They ensure that equipment is in optimal condition, identifies any wear and tear before it becomes a hazard, and provides a clear audit trail for accountability. For many businesses, particularly those with diverse work sites or large teams, having a standardized, easy-to-use fall protection inspection form template can streamline this vital process, ensuring consistency and thoroughness across all operations.

Why a Robust Fall Protection Inspection Form is Non-Negotiable

Having a well-designed fall protection inspection form is more than just a bureaucratic checkbox; it is a critical tool for maintaining workplace safety and compliance. Regulatory bodies like OSHA in the United States or local equivalent agencies often mandate regular inspections of personal fall arrest systems and other fall protection equipment. Failing to comply can result in hefty fines, legal liabilities, and, most importantly, preventable accidents or fatalities. A standardized template helps ensure that no critical inspection point is overlooked, making it easier to meet and exceed these regulatory requirements.

Beyond mere compliance, a comprehensive form helps in the early detection of issues. Equipment, even the most durable, undergoes wear and tear from use, environmental exposure, and even improper storage. A systematic inspection using a detailed template allows inspectors to identify frayed webbing, corroded hardware, stretched elastic, or damaged stitching before these minor defects escalate into dangerous failures. This proactive approach saves lives and extends the lifespan of expensive safety equipment.

Furthermore, a consistent inspection form provides invaluable data for maintenance and replacement schedules. By tracking the condition of specific pieces of equipment over time, you can gain insights into usage patterns, identify frequently damaged items, and forecast when certain components will need replacement. This data-driven approach allows for more efficient budget allocation for safety equipment and reduces unexpected downtime due to equipment failure. It also serves as a historical record, demonstrating due diligence in the event of an incident or audit.

Key Elements of an Effective Form

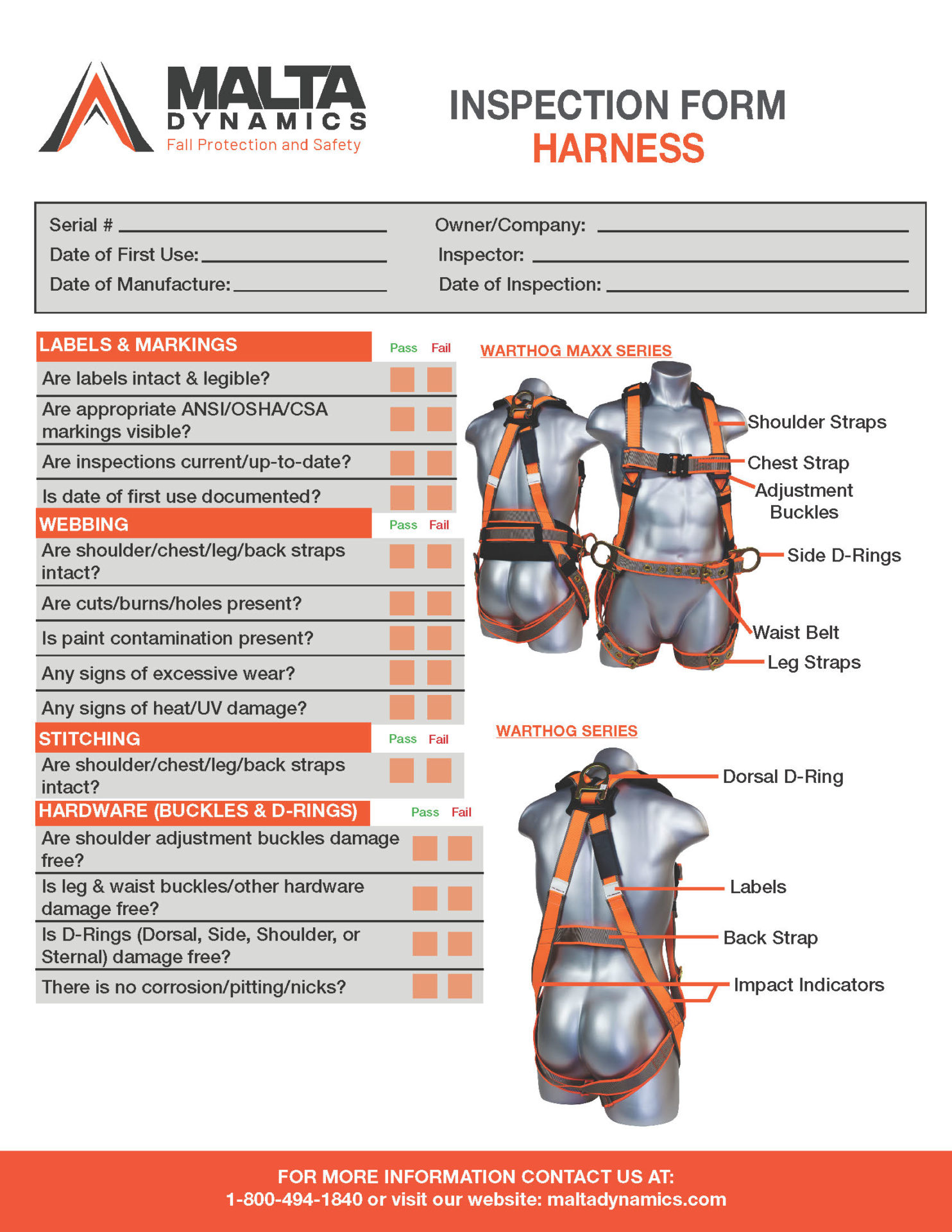

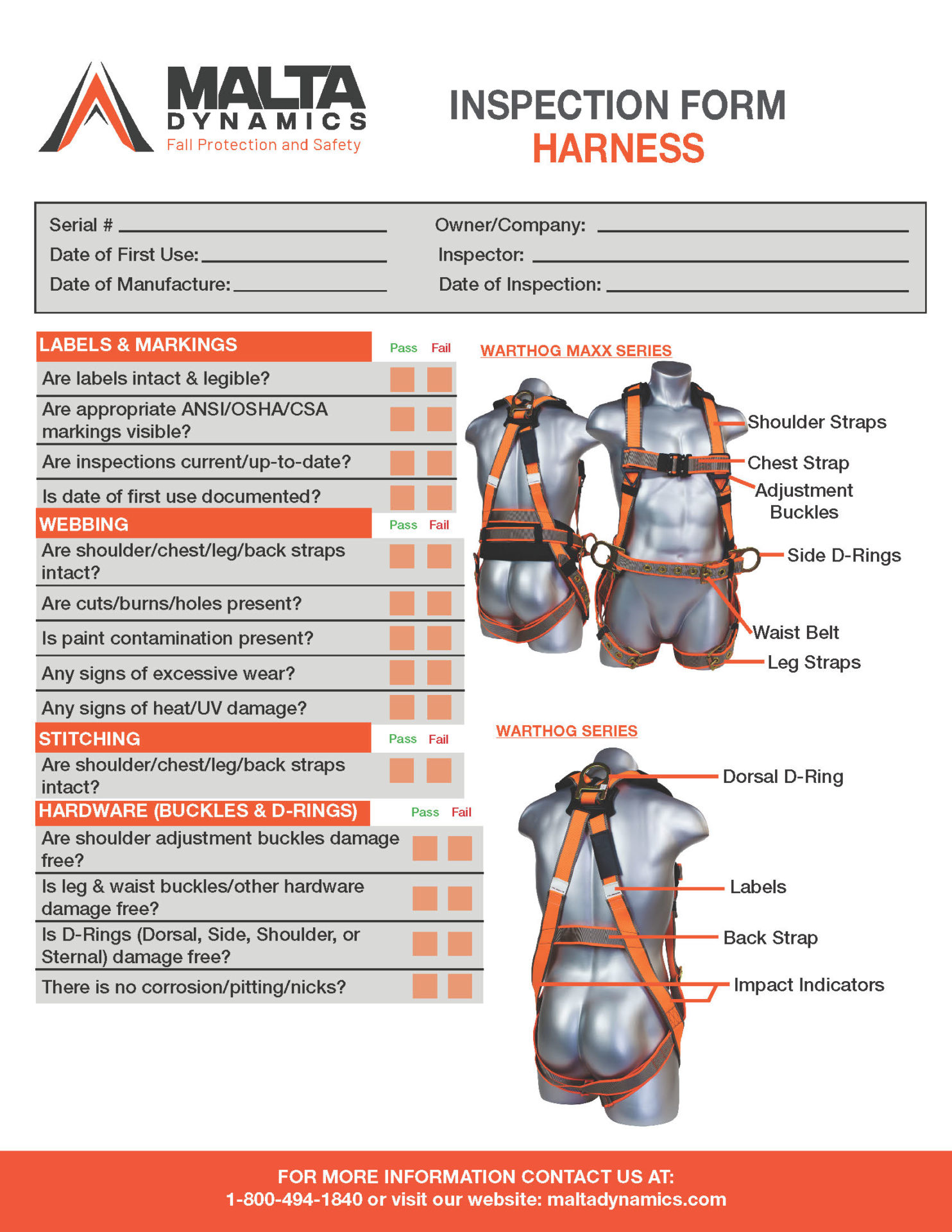

An effective fall protection inspection form should cover all critical aspects of the equipment and the inspection process. While specific needs may vary, a good template generally includes:

- Date and time of inspection

- Inspector’s name and signature

- Equipment type (e.g., full-body harness, lanyard, self-retracting lifeline)

- Unique identification number for each piece of equipment

- Manufacturer and model number

- Date of manufacture and last inspection

- Condition of components (webbing, stitching, D-rings, buckles, hardware, energy absorber, labels)

- Pass or fail status for each component and overall equipment

- Action required (e.g., approved for use, repair, dispose)

- Any additional comments or observations

This detailed approach ensures thoroughness and provides a clear record of the equipment’s status.

Choosing and Customizing Your Fall Protection Inspection Form Template

When it comes to selecting or creating a fall protection inspection form template, one size rarely fits all. The ideal template will be tailored to the specific types of fall protection equipment used in your workplace and the unique hazards present in your working environment. Consider whether your team primarily uses full-body harnesses and lanyards, or if you also integrate vertical lifelines, horizontal lifelines, confined space retrieval systems, or specialized anchor points. Each type of equipment has distinct inspection points that need to be clearly listed and evaluated on your form.

Customization is key to making the template truly effective. While generic templates can provide a good starting point, modifying them to include specific branding, internal equipment identification numbers, or even custom fields for unique site conditions can greatly enhance their utility. For instance, if your work involves environments with extreme temperatures or corrosive substances, you might add specific checks for material degradation related to those conditions. The goal is to make the form intuitive for your inspectors and comprehensive for your record-keeping.

Effective implementation of your chosen fall protection inspection form template also requires proper training for all personnel involved. Inspectors must be competent and understand what to look for, how to properly identify defects, and the importance of accurate record-keeping. This training should cover not only the mechanics of inspection but also the proper use of the form itself. Consistent training ensures that everyone performs inspections to the same high standard, thereby maximizing the safety benefits.

Finally, consider the format of your template. While paper forms are traditional, many companies are moving towards digital solutions for their inspection processes. Digital forms can offer advantages such as automatic timestamping, photo attachments, instant data synchronization, and easier trend analysis. Whether you opt for a printable PDF or a mobile-friendly app, ensure the fall protection inspection form template is accessible, easy to fill out, and allows for efficient storage and retrieval of critical safety data.

Regular, systematic checks using a well-designed inspection form are not merely about ticking boxes; they are fundamental to creating a safe working environment. By embracing a proactive approach to equipment maintenance and documentation, businesses can significantly reduce the risk of incidents and build a stronger safety culture. Prioritizing thorough inspections helps ensure that every piece of gear is ready to perform its vital function when it matters most, providing peace of mind for both workers and management.