Working in the field often means facing dynamic, unpredictable environments. Unlike a controlled factory floor, construction sites, outdoor maintenance tasks, or even quick service calls can present new hazards with every change in weather, equipment, or personnel. Ensuring the safety of your team in such situations isn’t just a regulatory requirement; it’s a fundamental commitment to their well-being. Proactive identification of potential dangers before work begins is absolutely critical to preventing accidents and injuries.

This is where the power of a well-designed field level hazard assessment form template comes into play. It provides a structured, systematic way to identify, evaluate, and control hazards on the spot, ensuring that nothing important is overlooked in the hustle and bustle of a busy workday. Think of it as your safety checklist, guiding your team through a thorough review of the work area and tasks before any tools are even picked up.

Understanding the Core of Field Level Hazard Assessments

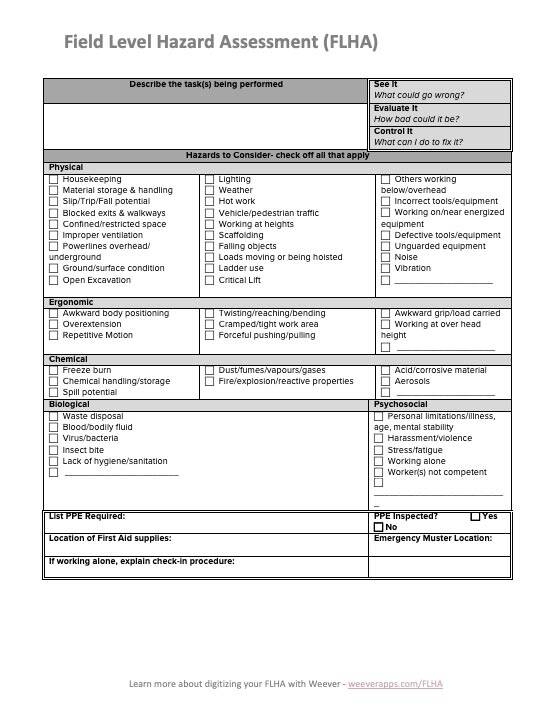

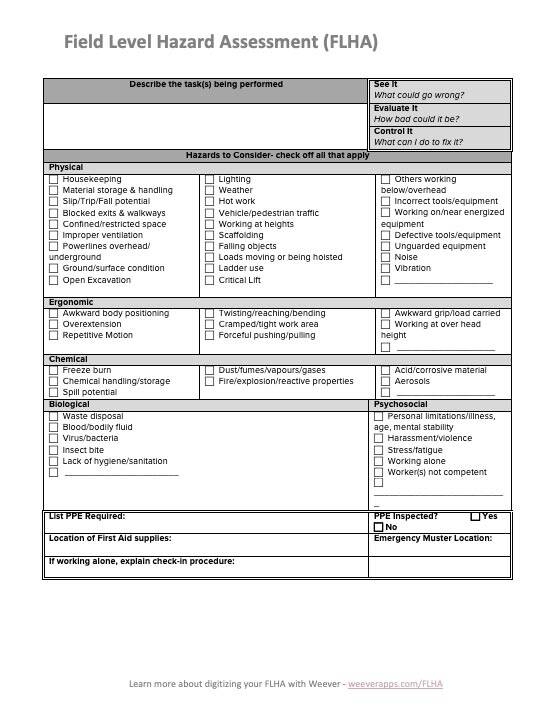

At its heart, a Field Level Hazard Assessment (FLHA) is a quick, on-site risk assessment performed immediately before work starts or when conditions change. Its primary purpose is to identify new or changing hazards that may not have been present or obvious during the initial project planning phase. This rapid assessment allows workers to implement appropriate controls to mitigate risks, ensuring their safety and the safety of those around them. It’s not about extensive paperwork; it’s about a brief, focused moment of reflection and planning.

Why is this level of immediate assessment so crucial? Imagine a crew arriving at a site that was clear yesterday, only to find a new excavation nearby, or unexpected overhead power lines. Without a rapid FLHA, these new hazards might go unnoticed until it’s too late. The assessment prompts workers to consider their surroundings, the specific tasks they’re about to undertake, the equipment they’ll use, and the potential interactions between these elements. It’s a living document, evolving with the work environment.

Furthermore, conducting an FLHA fosters a strong safety culture. It empowers workers to take ownership of their safety and encourages open communication about potential dangers. When everyone on the team understands the process and participates, it creates a collective awareness that significantly reduces the likelihood of incidents. It shifts the mindset from reacting to accidents to proactively preventing them.

Using a consistent field level hazard assessment form template helps standardize this vital process across your organization. It ensures that every team member, regardless of their experience level, follows the same logical steps for hazard identification and control. This consistency minimizes the chance of critical steps being missed and provides a clear record of the safety measures taken, which can be invaluable for continuous improvement and compliance.

Key Benefits of a Standardized FLHA Template

- Ensures consistent hazard identification and control across all tasks and teams.

- Reduces the likelihood of overlooked hazards by providing a structured checklist.

- Promotes a proactive safety mindset among all field personnel.

- Facilitates better communication about risks and control measures within the team.

- Provides a documented record of the safety assessment for compliance and review.

- Speeds up the assessment process by pre-filling common sections and prompts.

Designing and Implementing Your Effective Template

Creating a truly effective field level hazard assessment form template isn’t just about listing potential hazards; it’s about designing a tool that is practical, easy to use, and comprehensive enough for your specific operations. A good template should guide the user through a logical thought process, prompting them to consider different categories of hazards, from environmental factors like weather and terrain to task-specific risks involving tools, equipment, and chemicals. It should also have clear sections for outlining control measures and assigning responsibilities.

When developing your template, think about the common types of work your teams perform and tailor the sections accordingly. Include spaces for basic job information, such as the date, location, crew members, and specific tasks. Then, dedicate significant sections to hazard identification, often broken down into categories like “people,” “equipment,” “environment,” and “process.” Following this, there should be sections for describing the chosen control measures (elimination, substitution, engineering controls, administrative controls, PPE) and a clear sign-off for all involved workers, indicating their understanding and agreement.

Implementing the template effectively goes beyond simply handing it out. It requires proper training for all field personnel on how to use it correctly and consistently. This training should emphasize the “why” behind the FLHA, not just the “how.” Encourage open discussion and ensure workers feel comfortable identifying and reporting hazards without fear of reprisal. Make it clear that the template is a tool to empower them, not just another piece of paperwork.

Regular review and updates to your field level hazard assessment form template are also essential. As new equipment is introduced, work processes change, or incidents occur, the template should be revised to reflect these developments. Gather feedback from the teams using the template most frequently; they are your best resource for identifying areas for improvement. A living, evolving template is far more effective than a static document that becomes quickly outdated.

- Job information: Date, location, project name, crew members.

- Task description: A brief overview of the work to be performed.

- Hazard identification: Space to list specific hazards categorized by type (e.g., slip, trip, fall; chemical exposure; confined space; electrical).

- Risk assessment: A simple method to rate the severity and likelihood of each identified hazard.

- Control measures: Sections to detail how each hazard will be controlled (e.g., lockout/tagout, ventilation, barricades, specific PPE).

- Emergency procedures: Quick reference or space to note site-specific emergency contacts and procedures.

- Worker sign-off: Signatures from all workers involved, indicating they understand the hazards and controls.

Embracing proactive safety measures is a hallmark of a responsible and effective operation. By systematically identifying and controlling risks before they lead to incidents, you’re not just complying with regulations; you’re actively safeguarding your most valuable asset: your people.

A well-utilized hazard assessment process empowers your teams, fosters a culture of vigilance, and ultimately contributes to a more productive and injury-free work environment. It’s an investment that pays dividends in safety, morale, and operational efficiency.