Heavy equipment is the backbone of many industries, from construction and agriculture to mining and logistics. These powerful machines represent a significant investment, and their continuous operation is absolutely vital for project timelines and overall profitability. When a piece of heavy equipment breaks down unexpectedly, it’s not just an inconvenience; it can lead to costly delays, missed deadlines, and a severe hit to your bottom line. That’s why a robust maintenance strategy isn’t just a good idea, it’s essential.

Without a systematic approach, maintenance can quickly become reactive, meaning you’re always fixing problems instead of preventing them. This is where a well-designed heavy equipment maintenance form template becomes an invaluable asset. It transforms scattered tasks into a streamlined, organized process, ensuring nothing is overlooked and every piece of equipment gets the attention it needs to perform optimally.

The Unmistakable Value of a Structured Maintenance Program

Implementing a structured maintenance program for your heavy equipment fleet is one of the smartest decisions you can make for your business. It moves you away from the chaotic cycle of unexpected breakdowns and into a proactive stance that extends the life of your machinery, enhances safety, and significantly cuts down on long-term costs. Think about it: an oil change today is far cheaper and less disruptive than an engine replacement tomorrow. A systematic approach helps you identify minor issues before they escalate into major, expensive failures.

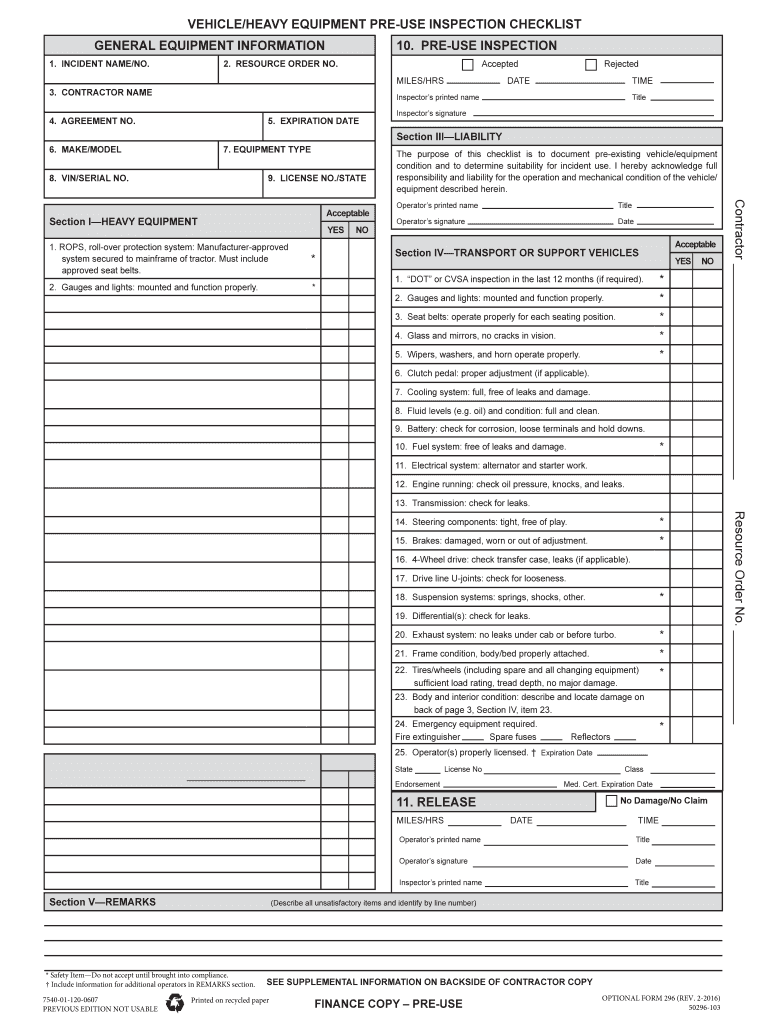

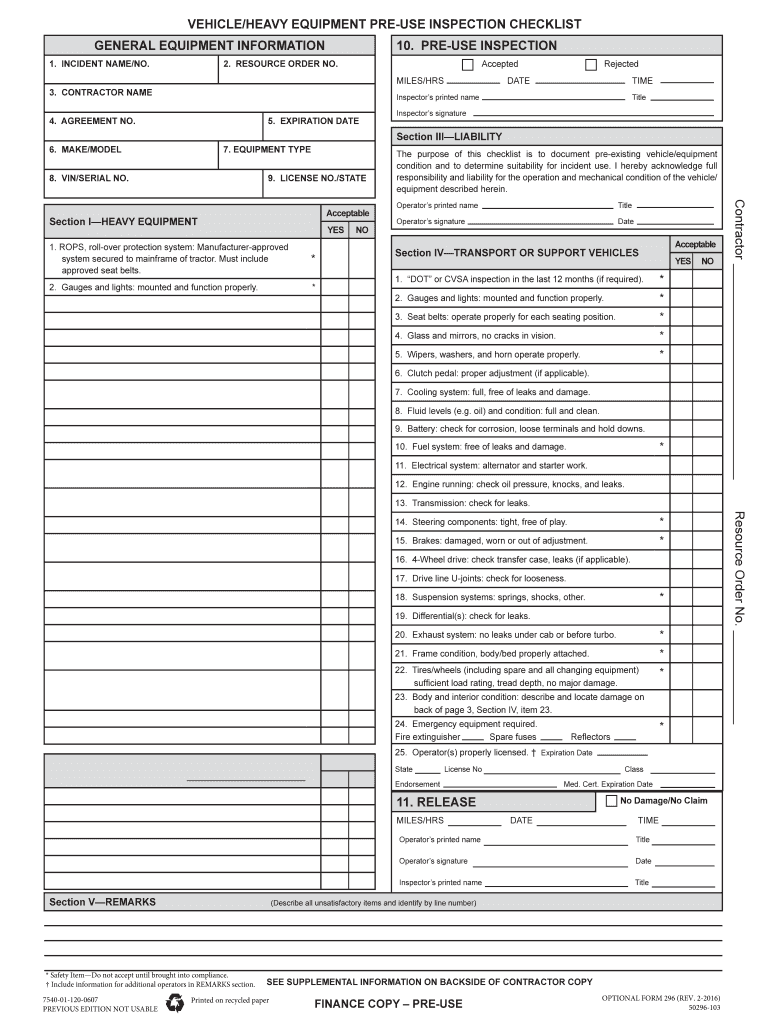

This is precisely where a heavy equipment maintenance form template truly shines. It provides a consistent framework for all your inspection and service tasks. Instead of relying on memory or haphazard notes, every technician follows the same procedure, checking off items on a comprehensive list. This standardization ensures that critical components are regularly inspected, fluids are topped off or replaced on schedule, and wear-and-tear items are addressed before they cause a breakdown. It creates a historical record for each machine, allowing you to track its service history, identify recurring issues, and predict future maintenance needs more accurately.

Beyond simply preventing breakdowns, a well-implemented maintenance form supports greater operational efficiency. When equipment is properly maintained, it runs more smoothly, consumes less fuel, and operates at its peak performance. This translates directly into higher productivity and better output for your projects. Furthermore, regular checks often reveal opportunities for minor adjustments that can improve performance or prolong the life of parts, leading to even greater savings.

Safety is another paramount benefit. Heavy equipment can be dangerous if not properly maintained. A systematic maintenance schedule, guided by a detailed form, ensures that all safety features, brakes, lights, and emergency stop systems are regularly checked and are in perfect working order. This not only protects your operators and other personnel on the job site but also helps you comply with industry regulations and standards, reducing the risk of accidents and potential liabilities.

Essential Elements for an Effective Maintenance Form

To get the most out of your form, ensure it includes these crucial sections:

- Equipment Identification: Unique ID number, make, model, serial number.

- Date and Time: When the inspection or service was performed.

- Operator/Technician Information: Name of the person who performed the work.

- Hour Meter/Odometer Reading: Crucial for tracking service intervals.

- Inspection Checklist: A comprehensive list of items to inspect, categorized (e.g., fluid levels, tires, tracks, lights, brakes, hydraulics, safety systems).

- Maintenance Performed: Space to detail services done (e.g., oil change, filter replacement, lubrication).

- Issues Found: Any defects, wear, or damage noted during inspection.

- Parts Used: List of replacement parts installed.

- Next Scheduled Service: Date or hour meter reading for the next planned maintenance.

- Sign-off: Signature lines for the technician and supervisor.

Making Your Heavy Equipment Maintenance Form Template Work for You

Once you understand the profound benefits, the next step is to actually put a heavy equipment maintenance form template into practice. There are many pre-made templates available online, or you can design one from scratch tailored precisely to your specific fleet and operational procedures. The key is to start simple and then iterate as you discover what works best for your team. Don’t feel pressured to create the perfect form on day one; focus on getting started and then refine it over time based on feedback from your technicians.

Customization is incredibly important. While a generic template might give you a head start, your heavy equipment fleet is unique. You might have specialized machinery, different operational environments, or specific regulatory requirements. Take the time to adjust the checklist items, add sections for unique components, or even modify the frequency of certain checks. For instance, equipment operating in dusty environments will need more frequent air filter inspections than one used in a cleaner setting. A form that truly fits your operations will be far more effective and less likely to be seen as a burden by your team.

Consider the format of your template. While traditional paper forms are still widely used, many businesses are migrating towards digital solutions. Digital forms, whether through dedicated maintenance software or simple spreadsheet applications, offer advantages like easier data entry, automated scheduling reminders, instant data analysis, and centralized storage that eliminates lost paperwork. However, paper forms can be beneficial in remote areas with no internet access or for initial implementation due to their simplicity. Choose the format that best suits your team’s tech-savviness and your operational context.

Finally, effective implementation relies heavily on clear communication and training. Simply handing out forms and expecting magic won’t work. Train your operators and technicians on how to properly fill out the heavy equipment maintenance form template, emphasizing why each section is important and how their diligent record-keeping contributes to the overall success and safety of the operation. Encourage feedback on the form itself; the people using it daily will have invaluable insights into how it can be improved. Regular reviews of completed forms can also help identify trends, flag recurring issues, and optimize your maintenance schedule.

By embracing a systematic approach to maintenance, bolstered by the consistent use of a detailed form, you’re not just performing routine checks; you’re building a foundation for long-term operational excellence. This proactive strategy ensures your machinery is always ready for action, minimizing downtime and maximizing the return on your significant investments. It’s about securing peace of mind, knowing that your most vital assets are being cared for, contributing reliably to every project you undertake.