In the bustling world of manufacturing and production, ensuring top-notch quality isn’t just a goal; it’s a necessity. Imagine a complex assembly line where products move from one station to the next, each stage adding intricate components or processes. Without a clear system to monitor quality at every step, defects can easily slip through, leading to costly reworks, scrap, and, worst of all, unhappy customers. This is precisely where the power of an in-process inspection form comes into play, acting as your vigilant guardian of quality throughout the production journey.

Having a standardized way to check things off as they happen is a game-changer. It’s not just about catching mistakes at the end; it’s about preventing them from compounding, ensuring that each component or sub-assembly meets specifications before moving forward. By establishing clear checkpoints and documenting observations, you build a robust quality assurance system that minimizes waste and maximizes efficiency. A well-designed template simplifies this crucial task, making it accessible and effective for everyone on the team.

Streamlining Your Production: Why an In Process Inspection Form Template is Essential

Thinking about quality control can sometimes feel like a massive undertaking, especially when you’re dealing with multiple production lines or complex products. However, the true beauty of an in process inspection form template lies in its ability to break down this large task into manageable, repeatable steps. It’s not just about ticking boxes; it’s about embedding a culture of quality right into the heart of your operations. Without a standardized template, different inspectors might focus on different aspects, leading to inconsistencies and gaps in your quality data. This lack of uniformity can make it incredibly difficult to identify recurring problems or pinpoint areas needing improvement.

By providing a clear, consistent framework, a template ensures that every critical point is checked, every time. This consistency is vital for maintaining product integrity and meeting regulatory standards. It transforms subjective observations into objective data, making it easier to track trends, identify common errors, and implement targeted corrective actions. Imagine trying to troubleshoot a recurring defect without consistent data from previous inspection points—it would be like trying to find a needle in a haystack, blindfolded!

Ensuring Consistent Quality

Consistency isn’t just a buzzword; it’s the bedrock of a reliable manufacturing process. When every inspector uses the same form, follows the same criteria, and records data in the same format, you eliminate ambiguity and human error. This standardization leads to:

- Uniform Data Collection: All critical information is captured in a predictable way, making it easier to analyze and interpret.

- Reduced Training Time: New team members can quickly understand what needs to be inspected and how to document it, thanks to the clear structure.

- Clear Expectations: Everyone involved knows exactly what quality standards need to be met at each stage.

- Proactive Problem Solving: Issues are identified early, often before they become major defects, allowing for quick resolution.

Ultimately, an effective in process inspection form template acts as your silent partner in quality assurance, helping you move from reactive problem-solving to proactive prevention. It empowers your team to take ownership of quality, fostering an environment where excellence is the norm, not the exception.

Crafting Your Perfect Template: Key Elements to Include

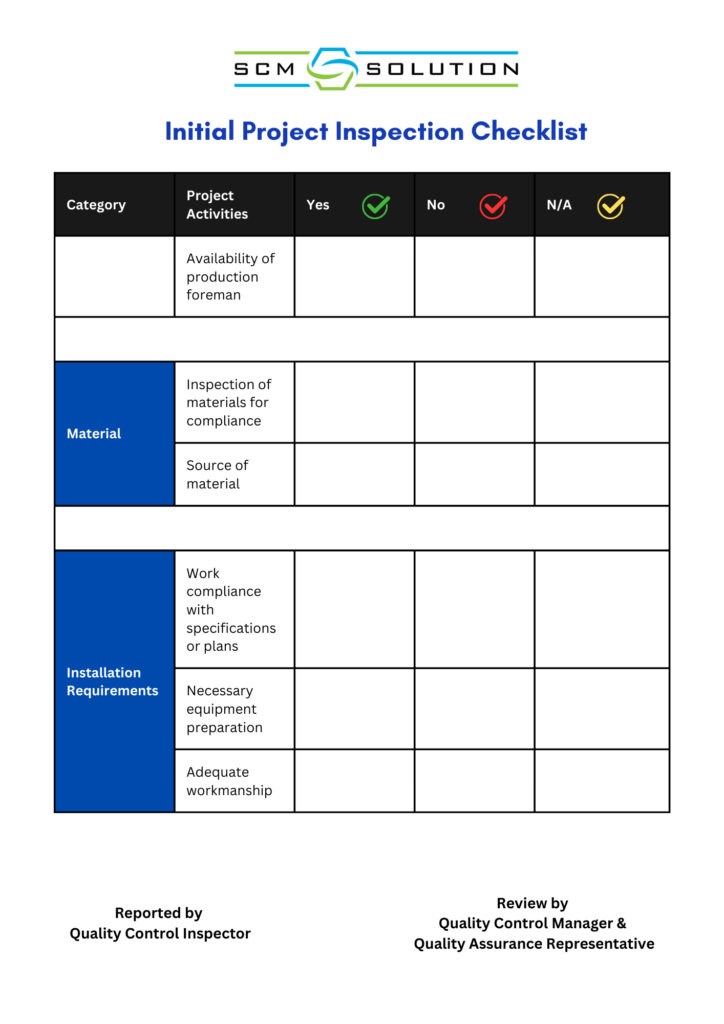

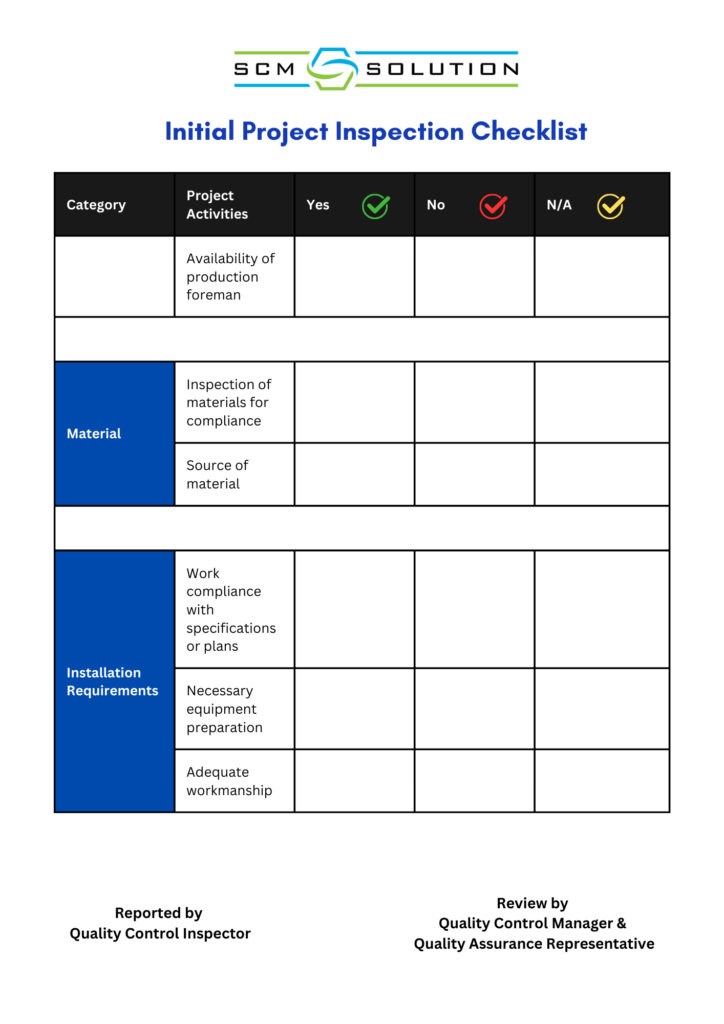

So, you’re convinced that an in process inspection form template is what you need. But what exactly goes into making an effective one? The goal is to create a document that is comprehensive enough to capture all necessary data, yet simple enough to be used efficiently by your team on the shop floor. It’s about striking the right balance between detail and practicality, ensuring that the form adds value without becoming a burden. Think of it as a roadmap for quality, guiding your team through each critical checkpoint.

A well-designed template starts with basic identification information. This includes details like the product name and code, the specific production line or work cell, the date and time of the inspection, and the name of the inspector. This foundational data is crucial for traceability, allowing you to link inspection results directly back to specific batches, shifts, or even individual operators if needed. Without these identifiers, your inspection data becomes just a jumble of numbers, difficult to assign context or accountability.

Next, you’ll want to detail the actual inspection points and criteria. This is the heart of your template. Break down the production process into distinct stages where critical quality checks are necessary. For each stage, specify what needs to be inspected, the acceptable tolerances or specifications, and the method of inspection (e.g., visual check, measurement with caliper, functional test). Providing clear, concise instructions here is paramount to avoid misinterpretation and ensure accuracy.

Consider including sections for:

- Part or Component Information: Specific details about the items being inspected at that stage.

- Tools/Equipment Used: Which tools were used for the inspection (e.g., calipers, gauges), along with their calibration status.

- Pass/Fail Criteria: Simple checkboxes or clear instructions for recording acceptance or rejection.

- Non-Conformance Details: A dedicated space to describe any deviations, including quantity, type of defect, and potential root cause.

- Corrective Actions: What steps were taken immediately to address any identified issues.

- Sign-offs: Spaces for the inspector, supervisor, or even the next process owner to sign off, indicating their approval or acknowledgment.

Finally, ensure your template is designed for easy data capture, whether it’s a paper form that encourages legible handwriting or a digital template that minimizes data entry errors. The easier it is for your team to use, the more likely it is that it will be consistently and accurately filled out, providing you with invaluable insights into your production quality.

Embracing the use of a standardized form for your in-process inspections is a significant step towards operational excellence. It transforms the abstract concept of quality into a tangible, measurable reality, allowing you to continuously monitor, improve, and ultimately, guarantee the integrity of your products.

By implementing this structured approach, you’re not just preventing defects; you’re building a more resilient, efficient, and reputable manufacturing operation. It’s an investment in your product, your team, and your customers’ trust, ensuring that every item leaving your facility meets the highest standards.