Ever felt that rush of new inventory arriving, only to be overwhelmed by the sheer volume and the nagging thought of potential errors? You are not alone. Many businesses, regardless of their size, grapple with ensuring that what arrives at their doorstep matches what was ordered in terms of quality, quantity, and specifications. This initial point of contact with your supply chain is incredibly critical, as mistakes here can ripple through your entire operation, leading to costly reworks, dissatisfied customers, and even production delays.

That is where a robust system for checking incoming goods comes into play. It is not just about counting boxes; it is about quality assurance from the very first moment. Having a standardized approach can save you a world of trouble and expense down the line. But how do you create such a system without reinventing the wheel every time a delivery truck pulls up? The answer often lies in a well-designed, easy-to-use incoming goods inspection form template, a tool that can transform a chaotic receiving process into a streamlined and efficient one.

Why an Incoming Goods Inspection Form Template is a Game-Changer

Implementing a dedicated incoming goods inspection process might sound like an extra layer of bureaucracy, but in reality, it is a foundational step for quality control and operational efficiency. Think of it as your first line of defense against costly mistakes. Without a clear, documented procedure, it is easy for discrepancies to go unnoticed, for damaged goods to be accepted, or for incorrect items to slip into your inventory, all of which can lead to significant problems later on, from production halts to customer returns.

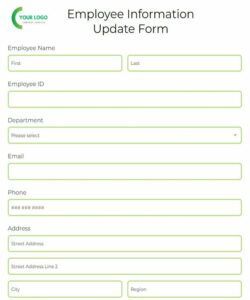

A standardized incoming goods inspection form template provides a consistent framework for every delivery. It ensures that every critical detail is checked, every necessary measurement is taken, and every potential issue is recorded. This consistency is vital because it reduces reliance on individual memory or varying standards, ensuring that your quality benchmarks are met uniformly across all incoming shipments. It also makes training new staff members much simpler, as the template clearly outlines the steps they need to follow.

Key Elements to Include in Your Form

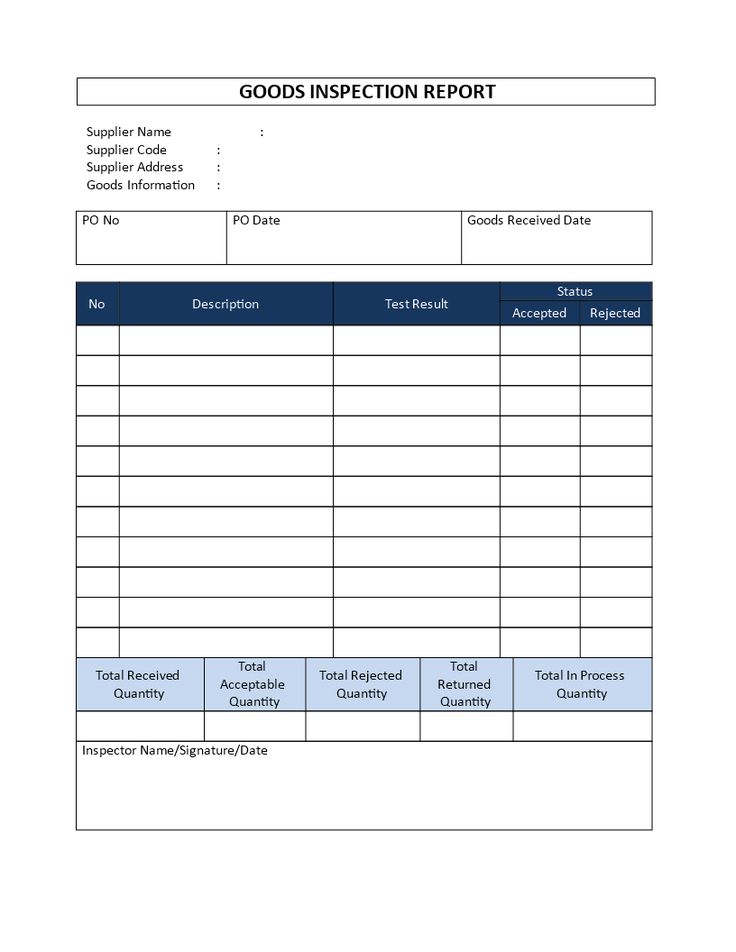

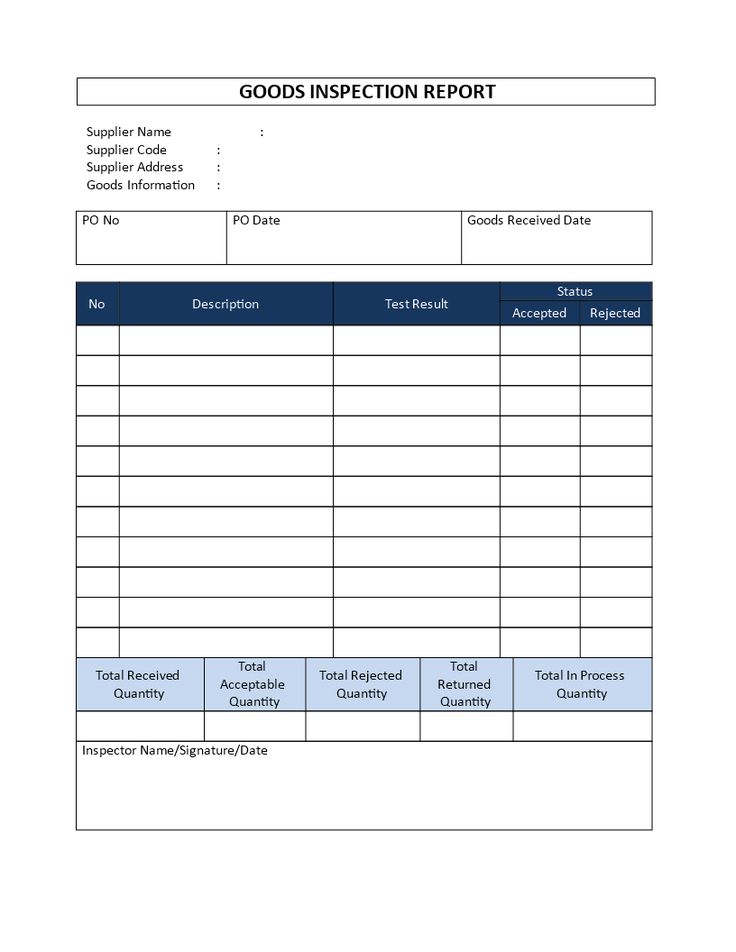

So, what exactly should an effective incoming goods inspection form template contain? It is more than just a checklist; it is a comprehensive document designed to capture all relevant information at the point of receipt. A well-structured template will guide your team through the necessary steps, ensuring nothing important is overlooked. While specific fields may vary based on your industry and the types of goods you receive, some core components are universally beneficial.

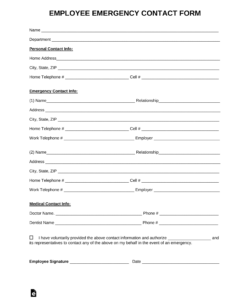

- Supplier Details: Essential for traceability, including the supplier name, contact information, and purchase order number.

- Delivery Information: Date and time of delivery, carrier name, tracking number, and the names of the personnel involved in receiving and inspecting.

- Product Identification: Clear details of the item received, such as part number, product description, quantity ordered, and quantity received. This is where you verify if you got what you asked for.

- Quality Check Parameters: This is critical. It should include specific fields for visual inspection (damage, contamination), dimensional checks (if applicable), batch numbers, expiration dates, and any specific quality standards or certifications required.

- Discrepancy Reporting: A dedicated section to note any variances from the order, including short shipments, over shipments, damaged goods, or incorrect items. This section should also allow for corrective actions to be documented.

- Acceptance or Rejection Status: A clear indicator of whether the goods were accepted, conditionally accepted, or rejected, along with reasons for rejection.

- Signatures and Dates: Proof of completion and accountability from the inspecting personnel.

By including these key elements, your form becomes a powerful record-keeping tool. It provides a historical log of all incoming materials, which is invaluable for auditing, supplier performance evaluation, and dispute resolution. Moreover, consistent use of the template helps identify recurring issues with specific suppliers or products, allowing you to address root causes proactively and improve your procurement processes over time.

Streamlining Your Process with the Right Template

Beyond simply having a form, the true power of an incoming goods inspection form template lies in its ability to streamline your entire receiving process. Imagine a scenario where every delivery is handled with the same level of diligence and precision, where potential issues are caught immediately, and where data is systematically collected for future analysis. This level of organization can significantly reduce errors, improve inventory accuracy, and enhance overall operational flow, saving both time and money.

The right template can also act as a crucial communication bridge between your receiving department, purchasing, and quality control. When a discrepancy is found, the detailed information captured on the form provides an immediate and undeniable record that can be quickly shared with the relevant departments. This enables faster decision-making on whether to return goods, negotiate with suppliers, or initiate non-conformance procedures, preventing delays in your production schedule or fulfillment process.

Furthermore, a well-designed template can be adapted for digital use, opening up even more possibilities for efficiency. Digital forms can be accessed on tablets or smartphones, allowing real-time data entry and immediate synchronization with your inventory management or ERP system. This eliminates manual data entry errors, speeds up the process, and provides instant visibility into your incoming stock, enabling better planning and resource allocation. Such integration transforms a static piece of paper into a dynamic tool for operational excellence.

Ultimately, investing time in creating or finding a suitable incoming goods inspection form template is an investment in your business’s overall health. It is about building a foundation of quality and accuracy right from the point of entry. It fosters a culture of accountability and precision, ensuring that the materials and products you rely on meet your exacting standards, every single time. This attention to detail at the receiving stage pays dividends across your entire operation.

In the end, optimizing your incoming goods process is not just about avoiding problems; it is about building a more robust, reliable, and efficient operation from the ground up. By systematically inspecting everything that comes through your doors, you are not only safeguarding your quality standards but also empowering your team with the tools they need to perform at their best. It is a proactive step that bolsters your supply chain, enhances customer satisfaction, and ultimately contributes to your business’s long-term success and reputation.

Embracing a structured approach to incoming deliveries means less stress, fewer mistakes, and more control over your inventory and production pipeline. It is about turning a potentially chaotic point into a well-oiled, strategic gateway for your business. The peace of mind that comes from knowing your initial quality checks are consistently thorough and documented is invaluable for any operation aiming for excellence.