In the intricate world of laboratory operations, maintaining impeccable standards of quality and safety is paramount. From diagnostic labs to research facilities, unexpected issues or non-conformances are an inevitable part of the daily routine. These could range from equipment malfunctions and failed calibrations to human errors or deviations from standard operating procedures. When such incidents occur, simply identifying the problem isn’t enough; what truly matters is how effectively you address it to prevent recurrence and ensure continuous improvement.

This is precisely where a robust corrective action process steps in, serving as the backbone of a laboratory’s quality management system. It’s a structured approach to not just fix the immediate problem, but to delve deeper, understand its root cause, implement lasting solutions, and verify their effectiveness. A well-designed system ensures compliance, enhances reliability, and fosters a culture of excellence.

Understanding the Core of Corrective Action in Laboratories

Every laboratory, regardless of its size or specialty, encounters situations that deviate from expected results or established protocols. These non-conformances are not failures but rather opportunities for learning and growth. The initial step is always to identify the problem clearly. This might come from internal audits, external inspections, customer complaints, quality control failures, or even routine observation by staff. Once an issue is identified, the clock starts ticking on a critical process: the corrective action.

Proper documentation throughout this process is not merely a bureaucratic hurdle; it is the cornerstone of accountability and continuous improvement. It allows laboratories to track issues over time, analyze trends, demonstrate compliance to regulatory bodies, and ensure that lessons learned are effectively integrated into future operations. Without a clear, standardized way to record and manage these actions, valuable insights can be lost, and recurrent problems become an unwelcome norm.

The goal isn’t just to put a band-aid on the immediate issue. A truly effective corrective action aims to prevent recurrence by addressing the underlying reasons. This often involves a systematic investigation to uncover the root cause. Was it a training gap, a faulty piece of equipment, an unclear procedure, or perhaps an environmental factor? Getting to the bottom of the problem is essential before any long-term solutions can be devised.

Once the root cause is identified, a concrete plan of action must be developed. This isn’t just about fixing the specific incident; it’s about implementing changes that prevent similar incidents from happening again. These changes could involve retraining staff, updating procedures, calibrating or replacing equipment, or even redesigning workflows. The final, yet crucial, step is to verify the effectiveness of the implemented actions, ensuring they have indeed solved the problem and are sustainable.

Key Elements of a Robust Corrective Action Process

- Identification: Clearly define the non-conformance or problem observed.

- Investigation: Conduct a thorough root cause analysis to understand why the problem occurred.

- Action Plan Development: Create specific, measurable, achievable, relevant, and time-bound (SMART) actions to address the root cause.

- Implementation: Put the planned corrective actions into effect.

- Verification of Effectiveness: Monitor and evaluate the implemented actions to ensure they have resolved the problem and prevented recurrence.

- Documentation and Review: Record all steps taken and review the overall process for lessons learned.

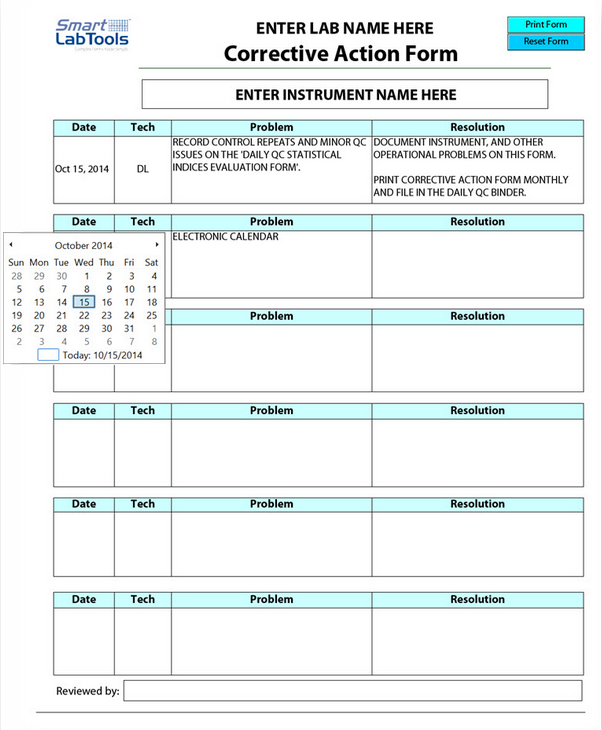

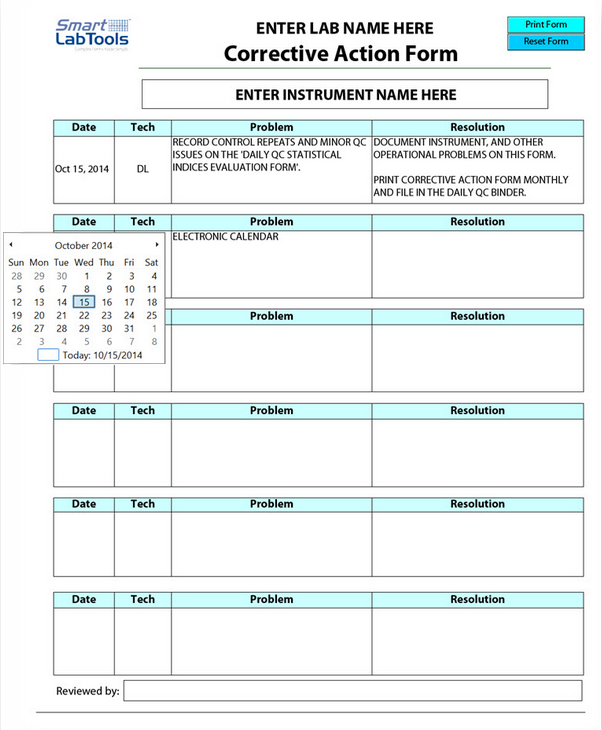

Designing Your Ideal Laboratory Corrective Action Form Template

When it comes to managing non-conformances and ensuring a systematic approach to quality improvement, having a standardized tool is incredibly beneficial. This is where a well-structured laboratory corrective action form template becomes an invaluable asset. It serves as a clear, consistent guide for everyone involved, ensuring that no critical step is missed and that all necessary information is captured from the moment an issue arises until it is fully resolved and verified.

A good template is not just a blank sheet; it’s a meticulously designed framework that prompts users for all essential details. It streamlines the entire process, making it easier for staff to report incidents accurately, for supervisors to assign investigations, and for quality managers to track progress and identify trends. Without such a template, each corrective action might be handled differently, leading to inconsistencies, omissions, and difficulties in auditing or demonstrating compliance.

The design of your template should be user-friendly, logical, and comprehensive. It should guide the user through each phase of the corrective action process, from describing the initial problem to documenting the root cause, outlining the corrective steps, and finally, verifying their effectiveness. Think of it as a narrative for your quality journey, ensuring every chapter is properly written and reviewed.

Furthermore, a standardized template supports training initiatives. New staff can quickly learn the proper procedure for handling non-conformances by following the fields within the template. It also fosters a proactive rather than reactive approach to quality, encouraging team members to think critically about why issues occur and how to prevent them. This structured approach is fundamental for maintaining accreditation, meeting regulatory requirements, and continuously enhancing the quality of laboratory services.

Here are some essential sections you should consider including in your laboratory corrective action form template:

- Incident Details: Space for describing the non-conformance, including date, time, location, affected equipment or process, and initial impact.

- Investigation Findings: A section dedicated to detailing the root cause analysis, including methodologies used (e.g., 5 Whys, Fishbone Diagram) and the identified underlying cause(s).

- Corrective Action Plan: Specific steps to be taken, responsible person(s), target completion dates, and resources required.

- Verification of Effectiveness: How and when the effectiveness of the implemented actions will be checked, and the results of this verification.

- Preventive Actions (Optional but Recommended): Any additional steps to prevent similar issues from occurring elsewhere or in the future.

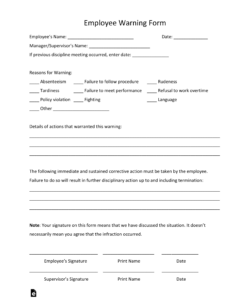

- Sign-offs and Approvals: Designated areas for signatures from the originator, investigator, approvers, and management review.

- Closure Date: The date the corrective action is officially closed.

Implementing a structured approach to corrective actions, supported by a well-designed form, is more than just good practice; it’s a strategic investment in the laboratory’s future. It empowers teams to learn from challenges, build resilience, and elevate the standard of their work consistently. This commitment to continuous improvement ultimately leads to greater accuracy, reliability, and trust in the services provided.