Every workplace, regardless of its size or industry, faces various risks, and manual handling is undeniably one of the most common culprits behind workplace injuries. From lifting heavy boxes to pushing equipment, these everyday tasks can lead to sprains, strains, and long-term musculoskeletal disorders if not managed properly. Proactive identification and mitigation of these risks are not just good practice; they are often a legal requirement, crucial for ensuring the safety and well-being of your employees.

That’s where a robust manual handling risk assessment form template comes into play. It provides a structured, systematic approach to evaluating tasks, identifying potential hazards, and implementing effective control measures. Instead of starting from scratch every time, a well-designed template streamlines the entire process, saving time and ensuring consistency across all assessments, making workplace safety management much more manageable and less daunting.

Why a Manual Handling Risk Assessment Template is Essential for Your Workplace

Adopting a comprehensive manual handling risk assessment form template is more than just ticking a box for compliance; it’s a fundamental step towards cultivating a genuinely safe and productive work environment. The legal framework in many countries mandates employers to assess and manage risks, and manual handling is frequently highlighted due to its high incidence of injuries. By using a template, you demonstrate due diligence, helping to protect your organization from potential legal liabilities and, more importantly, protecting your employees from harm.

Beyond legal obligations, the practical benefits of using a template are immense. It provides a standardized framework, ensuring that every assessment covers all critical aspects. This consistency means you won’t accidentally overlook a crucial hazard, and the quality of your risk management will remain high across different departments or tasks. Moreover, a template acts as a valuable record-keeping tool, allowing you to track changes, monitor the effectiveness of control measures, and easily retrieve information during audits or incident investigations. This structured approach simplifies what could otherwise be a complex and time-consuming process.

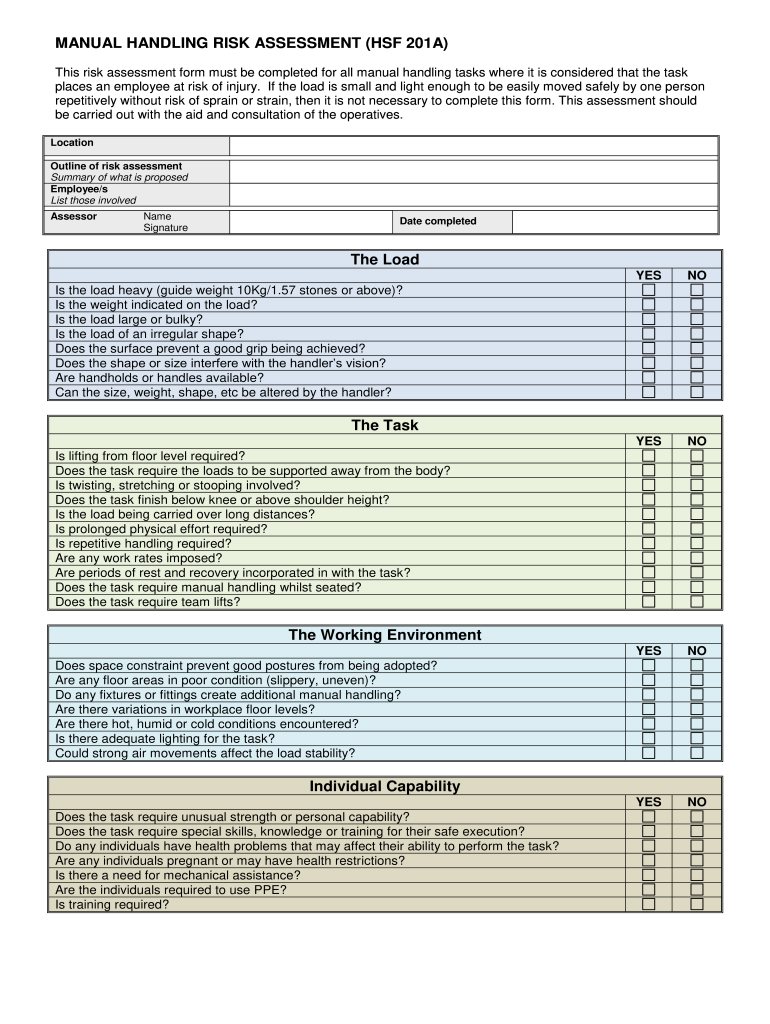

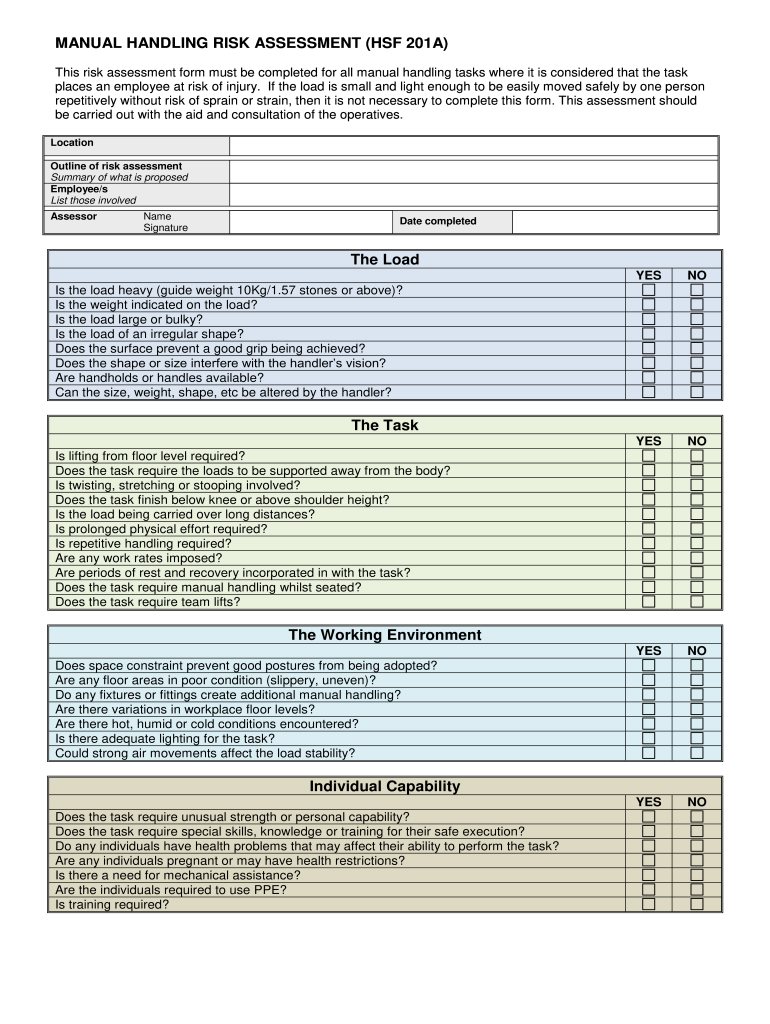

Common manual handling risks can range from simple awkward postures to repetitive movements, pushing, pulling, or sudden, heavy lifts. A well-designed template guides you through the process of systematically identifying these specific risks within your operations. It prompts you to consider factors like the weight, size, and shape of the load, the environment in which the task is performed, the capabilities of the individual performing the task, and the nature of the task itself. This holistic view ensures that all potential injury pathways are considered and addressed, leading to more effective risk control.

Ultimately, a template empowers you to move from identifying risks to actively managing them. It’s a foundational tool for developing a proactive safety culture where risks are anticipated and controlled before they lead to an incident. By standardizing your approach, you also facilitate better communication among team members regarding safety protocols, ensuring everyone is on the same page regarding safe manual handling practices.

Key Elements to Look For in a Template

- Task Description and Location: Clear details of the specific manual handling activity being assessed.

- Personnel Involved: Identification of who performs the task and their relevant training.

- Risk Factors (LITE): Sections to evaluate Load, Individual, Task, and Environment factors.

- Existing Control Measures: Documentation of current safety measures already in place.

- Identified Hazards and Risks: Specific risks related to the task, categorized by severity.

- Proposed Control Measures: Recommendations for new or improved controls, following the hierarchy of control.

- Responsible Person and Deadline: Assignment of actions to individuals with target completion dates.

- Review Date and Sign-off: Ensuring regular review and proper authorization of the assessment.

How to Effectively Use Your Manual Handling Risk Assessment Form Template

Implementing a manual handling risk assessment form template effectively requires more than just filling in blanks; it demands a thoughtful, systematic approach. The first step involves clearly defining the scope of the assessment. Which specific tasks or areas within your workplace pose manual handling risks? It’s often helpful to walk through the workspace, observing tasks as they are performed and speaking with employees who routinely engage in manual handling. Their direct experience and insights are invaluable for pinpointing real-world challenges and potential hazards that might otherwise be overlooked. Involving them from the outset fosters a sense of ownership and improves the quality of the assessment.

Once you’ve identified the tasks, the next phase is to meticulously assess each one using your template. This means evaluating the “LITE” factors: the Load (is it heavy, awkward, unstable?), the Individual (do they have the necessary strength, training, or health conditions?), the Task (does it involve repetitive movements, long distances, or constrained postures?), and the Environment (are there obstacles, poor lighting, or slippery surfaces?). Be as detailed as possible in your observations and descriptions, recording everything that contributes to the risk. This thoroughness is critical for truly understanding the nature of the hazard.

Following the identification of risks, the crucial step is to determine and implement appropriate control measures. The hierarchy of controls should always be your guiding principle: eliminate the risk if possible, substitute the hazardous task, engineer controls (e.g., trolleys, hoists), apply administrative controls (e.g., rotation of tasks, training), and as a last resort, provide personal protective equipment (PPE). For each identified risk, specify a clear, actionable control measure within your template, assign responsibility for its implementation, and set a realistic deadline. This structured approach ensures that identified issues are not just noted, but actively addressed.

Finally, a risk assessment is not a one-off event. It’s a continuous process. Regular review of your manual handling risk assessments is paramount, especially after any changes in tasks, equipment, or personnel, or following an incident. The template should include a section for review dates, prompting you to revisit and update the assessment periodically. This ensures that your control measures remain effective and relevant over time, adapting to the evolving needs of your workplace and continuing to safeguard your workforce from potential manual handling injuries.

By integrating a comprehensive manual handling risk assessment form template into your safety management system, you’re not just complying with regulations; you’re actively building a safer and more efficient workplace. This proactive approach minimizes the risk of injuries, reduces lost workdays, and fosters a positive safety culture where everyone understands their role in preventing manual handling incidents. It empowers your team with the knowledge and tools to perform their duties safely, contributing to overall well-being and productivity.

Embracing systematic risk management through a well-utilized template is a smart investment for any organization. It transforms potential hazards into manageable risks, ensuring that your employees can perform their jobs confidently and safely, ultimately leading to a healthier workforce and a more resilient business operation. Prioritizing safety through thorough assessments truly is a win-win for everyone involved.