In the dynamic world of manufacturing, efficiently managing inventory is paramount to success. Imagine a scenario where you consistently meet customer demand without accumulating excessive stock or facing frustrating shortages. This ideal state is often achieved through a well-executed “build to stock” strategy, where products are manufactured based on anticipated demand and then held in inventory, ready for immediate shipment.

While the concept sounds straightforward, its implementation requires meticulous planning, accurate forecasting, and a structured approach. That’s where a standardized process, often facilitated by a comprehensive form template, becomes invaluable. A clear, consistent framework ensures that every step from raw material procurement to finished goods storage is aligned with your production goals and market needs, helping you maintain a competitive edge and optimize operational efficiency.

Streamlining Your Production with a Robust Build-to-Stock Framework

For many manufacturers, the build to stock model is a cornerstone of their operations, especially for products with stable or predictable demand. It allows companies to achieve economies of scale in production, reduce lead times for customers, and leverage bulk purchasing discounts for raw materials. However, without a clear roadmap, this strategy can quickly lead to pitfalls like overproduction, tying up valuable capital in unsold goods, or underproduction, resulting in missed sales opportunities and dissatisfied customers.

The core challenge lies in balancing supply with demand effectively. This balance isn’t just about guessing; it’s about data-driven decisions and systematic execution. Relying on ad hoc methods or fragmented information can introduce significant risks and inefficiencies into your production cycle. This is precisely why a structured approach, often encapsulated within a well-designed form, is not just helpful but essential for optimizing your manufacturing processes.

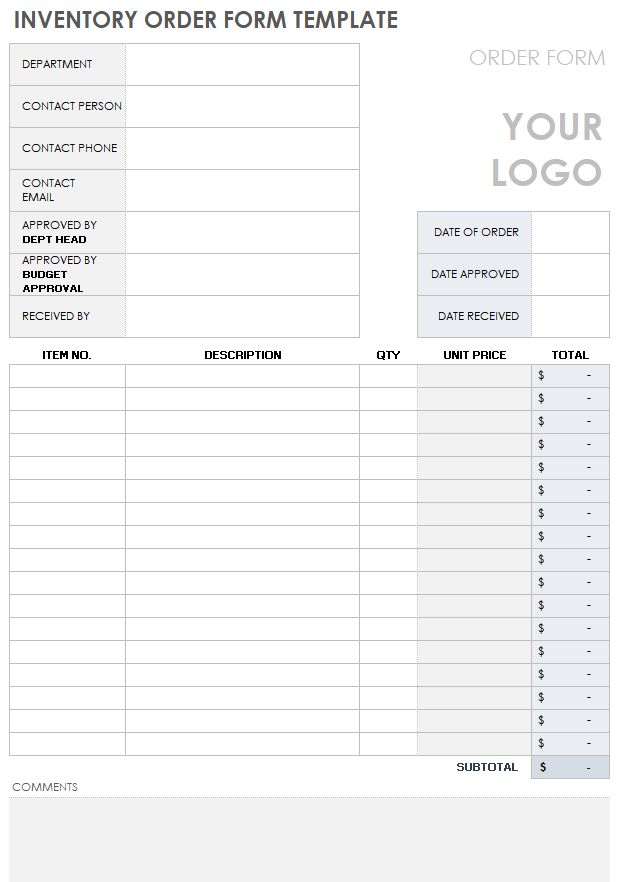

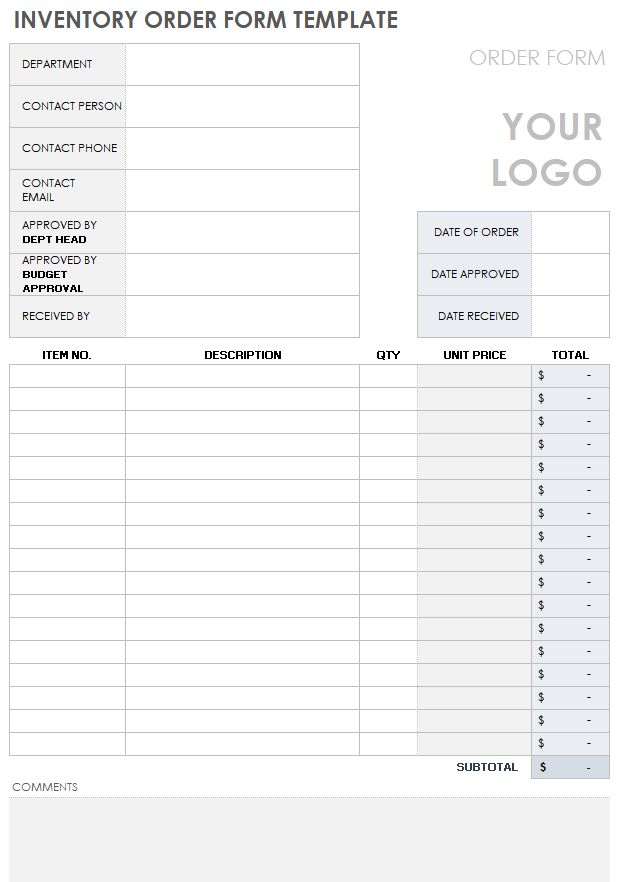

A dedicated manufacturing build to stock form template serves as a centralized hub for all critical information related to your inventory and production plans. It acts as a standardized checklist and data capture tool, ensuring that all relevant departments are on the same page, from sales and marketing providing forecasts to procurement, production, and warehousing executing the plan. This consistency minimizes errors, enhances communication, and provides a clear audit trail for continuous improvement.

Consider the myriad details that need to be tracked and coordinated for a successful build-to-stock operation. A template brings order to this complexity, ensuring no vital piece of information is overlooked. It helps you formalize the planning process, making it repeatable and scalable across different product lines or production runs.

Key Components of an Effective Build-to-Stock Form

- Product Identification: Clear details about the product, including SKU, description, and specifications.

- Demand Forecast: Quantified projections of future sales based on historical data, market trends, and promotional activities.

- Inventory Status: Current stock levels of raw materials, work-in-progress, and finished goods.

- Production Schedule: Planned start and end dates for manufacturing runs, including daily or weekly output targets.

- Material Requirements: A breakdown of all components and quantities needed for the planned production volume.

- Cost Analysis: Estimated production costs per unit, including labor, materials, and overhead.

- Quality Control Checkpoints: Specific points in the process where quality assurance is performed.

- Responsible Parties: Clear assignment of roles and responsibilities for each stage of the build-to-stock process.

Implementing and Optimizing Your Build-to-Stock Process

Beyond simply filling out a form, the true power of a manufacturing build to stock form template lies in its consistent application and integration into your operational workflow. Implementing this template means establishing clear protocols for its use: who fills it out, when it’s updated, and how the information flows between departments. This formalized approach transforms what might be an intuitive process for some into a robust, repeatable system for everyone involved.

The benefits extend far beyond just organizational neatness. By standardizing your build-to-stock planning, you can significantly reduce the risk of stockouts or overstock situations, leading to improved customer satisfaction due to readily available products. Furthermore, it helps optimize warehouse space utilization and minimizes capital tied up in slow-moving or obsolete inventory, directly impacting your bottom line and freeing up resources for other strategic investments.

However, the journey doesn’t end once the template is implemented. The effectiveness of any build-to-stock strategy is directly tied to the accuracy of its underlying forecasts. Market conditions, consumer preferences, and supply chain dynamics are constantly evolving. Therefore, it’s crucial to view your template as a living document that requires regular review and refinement. This iterative process ensures that your production plans remain aligned with current realities.

To truly optimize your build-to-stock process, establish a feedback loop where actual sales data and inventory performance are regularly compared against the initial forecasts and production plans. This analysis allows you to identify discrepancies, understand their root causes, and adjust your forecasting models and template fields accordingly. Incorporating insights from sales, marketing, and logistics teams can provide a holistic view and lead to more accurate and resilient inventory strategies.

By diligently using and refining your manufacturing build to stock form template, you empower your team with a clear, actionable plan. This structured approach not only improves operational efficiency but also enhances responsiveness to market changes, ensuring that your products are available when and where your customers need them, without incurring unnecessary costs from excess inventory.

A well-managed build-to-stock operation hinges on precision and foresight. By embracing a systematic approach, facilitated by a comprehensive template, manufacturers can transform complex inventory challenges into opportunities for growth and efficiency. This framework provides the clarity needed to make informed decisions, ensuring a smooth flow from production line to customer.

Ultimately, the goal is to create a seamless and profitable supply chain. Through consistent application of standardized processes and a commitment to continuous improvement, businesses can optimize their inventory levels, reduce operational costs, and build a reputation for reliability, securing their position in a competitive market.