In the fast-paced world of manufacturing, unexpected issues are an unavoidable part of the process. Whether it is a product defect, a machine malfunction, or a deviation from quality standards, these problems can disrupt operations, impact customer satisfaction, and lead to significant financial losses if not addressed swiftly and effectively. The key isn’t just to fix the immediate problem, but to prevent it from happening again.

This is where a structured approach to problem-solving becomes invaluable. Simply patching up an issue might provide a temporary fix, but it rarely tackles the root cause. To truly foster a culture of continuous improvement and ensure long-term operational excellence, manufacturers need a systematic way to identify, analyze, correct, and prevent recurrence of non-conformities. And often, the best place to start streamlining this vital process is with a robust manufacturing corrective action form template.

Why Your Manufacturing Process Needs a Robust Corrective Action Plan

Every manufacturing facility, regardless of its size or product, will encounter problems. From minor deviations in product specifications to major equipment failures, these issues demand attention. Without a clear, systematic plan for addressing them, companies risk repeated mistakes, escalating costs, and a decline in product quality and customer trust. A strong corrective action plan isn’t just about fixing a problem; it’s about learning from it and becoming better.

A corrective action plan goes beyond immediate repair. It involves a thorough investigation to determine the root cause of an issue, developing specific actions to eliminate that cause, implementing those actions, and then verifying their effectiveness to ensure the problem does not reappear. This proactive approach saves resources in the long run by preventing future disruptions, improving overall efficiency, and enhancing product consistency. It transitions a reactive environment into a more stable, predictable, and quality-focused operation.

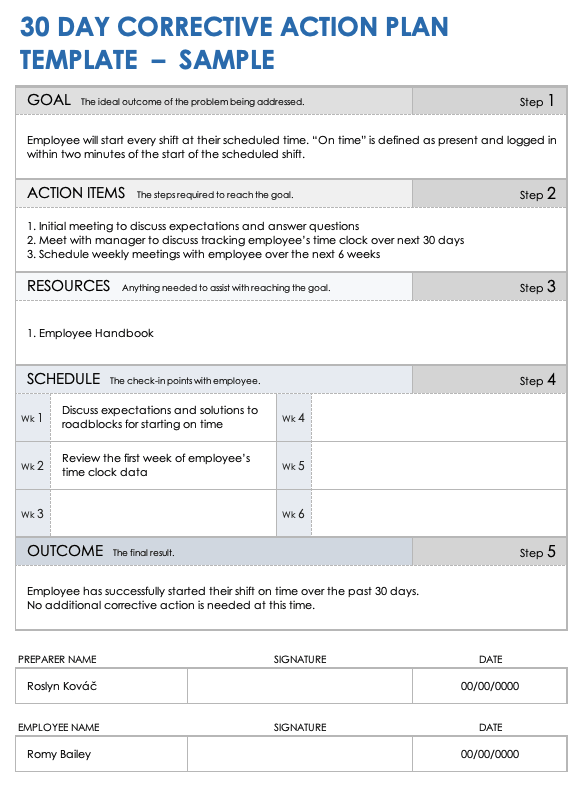

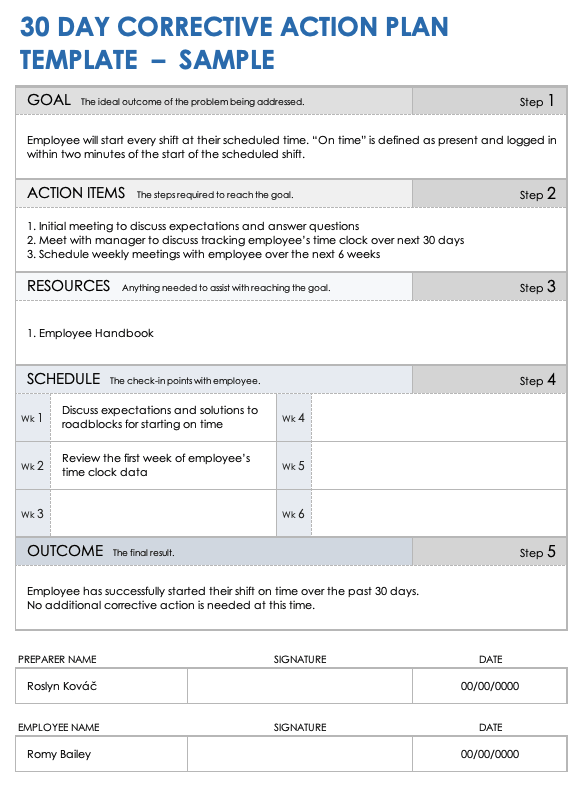

The real power of a dedicated manufacturing corrective action form template lies in its ability to standardize this critical process across your entire organization. Instead of different departments or individuals handling issues in their own way, a template provides a consistent framework. It ensures that every necessary step, from initial problem description to final verification, is documented and followed. This not only streamlines the investigation process but also creates a valuable historical record of issues and their resolutions, which can be crucial for audits, training, and ongoing improvement initiatives.

Without such a standardized template, organizations often face common pitfalls: incomplete investigations, actions that don’t truly address the root cause, and a lack of proper follow-up. Information can be lost, responsibilities unclear, and lessons unlearned. This can lead to the same problems recurring repeatedly, eroding efficiency and confidence. A well-designed template acts as a guide, ensuring no critical steps are missed and that accountability is maintained throughout the problem-solving journey.

Key Elements of an Effective Corrective Action Process

- Problem Identification and Description: Clearly defining the non-conformity.

- Containment Actions: Immediate steps to prevent further damage or impact.

- Root Cause Analysis: Investigating to find the underlying reason for the problem.

- Corrective Actions: Developing and implementing solutions to eliminate the root cause.

- Verification of Effectiveness: Confirming that the implemented actions have resolved the issue and prevented recurrence.

- Documentation and Closure: Recording all steps and formally closing the action.

Building Your Own Manufacturing Corrective Action Form Template

While many generic templates are available, understanding the core components allows you to tailor a manufacturing corrective action form template that perfectly fits your specific operational needs and industry regulations. Designing your own or customizing an existing one ensures it integrates seamlessly with your existing quality management systems and company culture. The goal is to create a tool that is intuitive to use and comprehensive enough to capture all necessary information for effective problem resolution.

A robust template should ideally include several distinct sections, each serving a crucial purpose. Starting with a clear area for problem description, including details like date, location, and affected product or process, sets the stage. This should be followed by sections dedicated to immediate containment actions and, critically, a detailed root cause analysis. This part often includes methodologies like 5 Whys or Fishbone diagrams. Then comes the planning and implementation of corrective actions, specifying who is responsible and by when. Finally, sections for verification of effectiveness and formal closure are essential to complete the loop, ensuring the problem is truly resolved and won’t reappear.

Beyond just designing the form, its effective implementation is paramount. This involves training all relevant personnel on how to accurately complete each section and understand the underlying principles of corrective action. Encouraging a culture where employees feel empowered to identify issues and initiate corrective actions, rather than just hiding them, is vital. Regular reviews of completed forms can also highlight common problem areas, leading to systemic improvements across the manufacturing process.

Ultimately, a thoughtfully constructed and consistently utilized manufacturing corrective action form template isn’t just a piece of paperwork; it’s a powerful instrument for continuous improvement. It empowers your team to systematically address non-conformities, reduces waste, enhances product quality, and helps you maintain compliance with industry standards and regulations. By providing a clear, repeatable framework for problem-solving, it transforms challenges into opportunities for growth and refinement within your operations, leading to greater efficiency and customer satisfaction.

Embracing a systematic approach to addressing non-conformities is a cornerstone of operational excellence in manufacturing. By meticulously documenting issues, uncovering their true origins, and implementing targeted solutions, businesses can prevent recurring problems that drain resources and erode trust. The structured nature of a well-designed form ensures that every critical step in the problem-solving lifecycle is consistently followed, fostering a culture of accountability and precision.

Investing time in developing and integrating an effective template for corrective actions pays dividends by transforming challenges into learning opportunities. It empowers teams to not just react to problems but to proactively prevent them, ultimately contributing to higher quality products, more efficient processes, and a stronger competitive edge in the market. This commitment to continuous improvement through structured problem-solving is what truly drives long-term success and resilience in the manufacturing sector.