In any operation that involves moving goods, materials, or equipment from one point to another, clarity and organization are paramount. Whether you are managing a busy construction site, overseeing warehouse logistics, or simply ensuring office supplies are distributed correctly, the process of picking up materials can often become a source of confusion, errors, or delays if not properly managed.

This is where a standardized system comes into play, offering a robust solution to bring order to what can otherwise be chaotic. A well-designed material pick up form template acts as a crucial tool, providing a clear, documented trail for every item collected. It ensures that everyone involved, from the person requesting the materials to the individual releasing them, is on the same page, minimizing misunderstandings and boosting overall efficiency.

Why a Material Pick Up Form Template is Your Go-To Solution

Imagine a scenario where materials are constantly being taken without a proper record. Who took what? When was it taken? Was it authorized? These questions can quickly lead to inventory discrepancies, project delays, and even financial losses. Without a systematic approach, it becomes nearly impossible to track valuable assets, assign accountability, or reconcile stock levels accurately. This lack of oversight can impact your bottom line and disrupt your operational flow significantly, making it harder to complete projects on time and within budget.

Implementing a material pick up form template directly addresses these challenges head-on. By requiring a documented process for every item removed from storage or inventory, you establish a clear audit trail. This simple yet powerful tool helps you maintain precise control over your assets, ensuring that every pickup is recorded with essential details. It transforms a potentially chaotic process into a streamlined, transparent operation, giving you peace of mind and better financial visibility.

Beyond mere tracking, a standardized form significantly reduces the likelihood of errors. When staff fill out a predefined template, they are prompted to provide all necessary information, leaving less room for assumptions or forgotten details. This clarity improves communication between departments, reduces the need for constant follow-ups, and helps in quickly resolving any discrepancies that might arise. It’s about creating a culture of accountability and precision throughout your material handling process, leading to smoother workflows and enhanced operational integrity.

Ultimately, having a dedicated template for material pickups empowers your team with the tools they need to operate more effectively. It’s not just about paperwork; it’s about fostering an environment where accuracy and responsibility are prioritized. To truly maximize the benefits, it’s important to include specific fields that capture all the critical information relevant to your operations. These are the details that transform a simple piece of paper into a vital tracking document.

Key Elements to Include

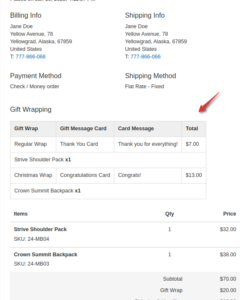

- Date and Time of Pickup

- Name and Contact Information of Person Picking Up

- Department or Project Affiliation

- Detailed Description of Materials (e.g., item number, type, model)

- Quantity of Each Material Item

- Reason for Pickup/Purpose

- Authorization Signature (from supervisor or inventory manager)

- Notes or Special Instructions

Customizing Your Template for Diverse Needs

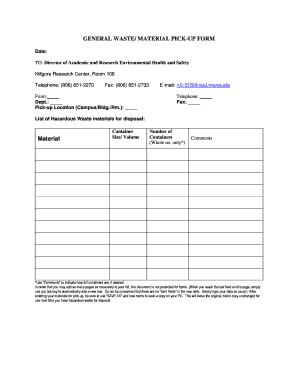

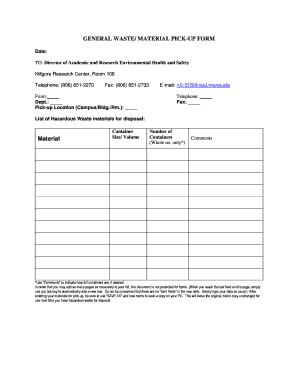

While the core purpose of a material pick up form template remains consistent – to document the retrieval of items – the specific details and fields required can vary greatly depending on your industry, business size, and the nature of the materials being handled. A small retail shop might only need basic information for stockroom withdrawals, whereas a large manufacturing plant would require extensive details for raw materials or parts, including batch numbers, lot numbers, or even quality control checks. The beauty of a template lies in its adaptability.

Think about how different sectors operate. In construction, a template might need fields for specific job site locations, phase of construction, and even equipment serial numbers, given the high value and mobility of items. For an IT department, tracking computer peripherals or software licenses might require fields for asset tags and user assignments. A versatile material pick up form template can be tailored to incorporate these unique identifiers and processes, ensuring it remains relevant and highly functional across various departments and industries, providing tailored precision.

The flexibility of these templates extends to their format as well. You can opt for a traditional printable form that can be filled out by hand, perfect for on-site use where digital access might be limited. Alternatively, a digital template, perhaps in a spreadsheet or a custom app, offers advantages like real-time data entry, automated tracking, and easier integration with inventory management systems. This digital approach can significantly reduce administrative burden and provide immediate insights into material flow, making data analysis much simpler and faster.

Customizing your template is about making it work for your unique challenges and maximizing its utility. By thoughtfully designing your material pick up form to reflect the specificities of your operations, you’re not just creating a document; you’re building an integral part of your inventory control and accountability framework. This proactive approach ensures that your system evolves with your business, continuously supporting efficient and error-free material management, no matter how complex your needs become.

- Consider adding fields for project codes or client names if you bill materials directly to specific jobs.

- Include a “Return Date” or “Expected Return” field for tools or reusable equipment.

- For regulated industries, ensure fields for compliance-related data, such as material safety data sheet (MSDS) references.

- Integrate barcode scanning capabilities into digital templates for faster and more accurate item identification.

Adopting a structured approach to material pickups significantly streamlines your operations, reducing waste, preventing loss, and improving overall accountability. This proactive step helps in maintaining accurate inventory levels and ensures that resources are always available when and where they are needed. It fosters a more organized and professional environment, benefiting everyone involved in your supply chain.

By implementing a well-designed form, you’re not just tracking items; you’re investing in the efficiency and integrity of your entire operational flow. The immediate benefits in time saved and errors avoided will quickly become apparent, making it an indispensable tool for any organization that values precision and control over its material assets. This foundational element empowers better decision-making and supports the smooth progression of all your projects.