Ever found yourself in a pickle trying to keep track of products, warranties, or even just individual items in your inventory? It’s a common challenge for businesses of all sizes, from bustling manufacturing plants to small retail shops. The sheer volume of items, each potentially needing its own unique identifier, can quickly become overwhelming without a structured approach. That’s where the humble but mighty serial number comes into play, providing a distinct identity for every single unit.

Managing these crucial numbers manually often leads to errors, lost data, and a whole lot of wasted time. Imagine the headache of a product recall without accurate serial number records, or the confusion when processing a warranty claim for an item whose origin is untraceable. This is precisely why having a robust new serial number form template isn’t just a good idea; it’s an absolute necessity for efficient operations and ultimate peace of mind. Let’s dive into how a well-designed template can transform your tracking process.

Why a Dedicated New Serial Number Form Template is Essential

In today’s fast-paced business world, precision in record-keeping is paramount. For any operation dealing with physical goods, from electronics and machinery to medical devices and consumer products, serial numbers are the DNA of individual units. They provide a unique identifier that distinguishes one item from countless others, making them indispensable for a wide array of business functions. Without a dedicated system to record and manage these numbers, businesses risk significant operational inefficiencies and potential financial losses.

Think about it: how do you manage warranties, track product lifecycles, or even identify counterfeit goods without a proper serial number log? A specialized new serial number form template ensures that every piece of critical information associated with an item’s unique identifier is captured consistently. This isn’t just about data entry; it’s about building a reliable database that supports various departments, from manufacturing and quality control to sales and customer service. It streamlines processes, reduces human error, and provides a clear audit trail for every product.

Beyond internal efficiencies, a well-maintained serial number log is crucial for external compliance and customer satisfaction. It simplifies product recalls by allowing precise identification of affected batches, minimizes warranty fraud, and enables quicker, more accurate support for your customers. Ultimately, investing in a proper form for recording serial numbers translates into better inventory management, enhanced security, and a more professional image.

Key Elements of an Effective Serial Number Form

- Product Name and Model Number: Clearly identify the item type.

- Serial Number: The unique identifier itself. This is the star of the show!

- Date of Manufacture/Assembly: Crucial for warranty and lifecycle tracking.

- Batch or Lot Number: Important for grouping products from the same production run.

- Customer Information (if applicable): For direct sales or warranty registration.

- Warranty Start/End Dates: Helps manage service agreements.

- Location/Storage Bin: For inventory management and retrieval.

- Operator/Inspector Initials: Accountability for who processed the item.

- Notes/Comments Section: For any specific details or observations unique to that item.

By including these key fields, your new serial number form template becomes a comprehensive tool, ensuring no vital detail is missed. This level of detail empowers your team with immediate access to crucial information, leading to faster problem-solving and improved decision-making across the board.

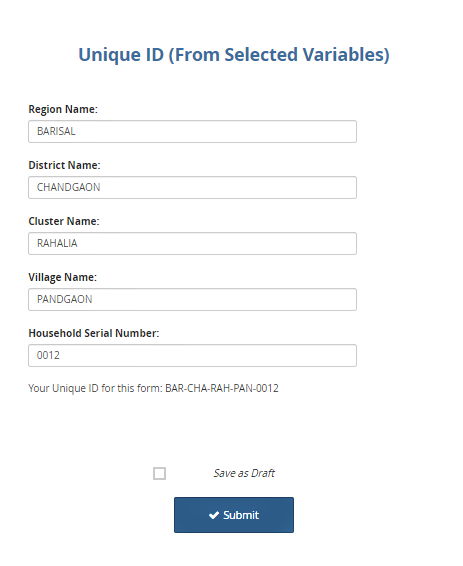

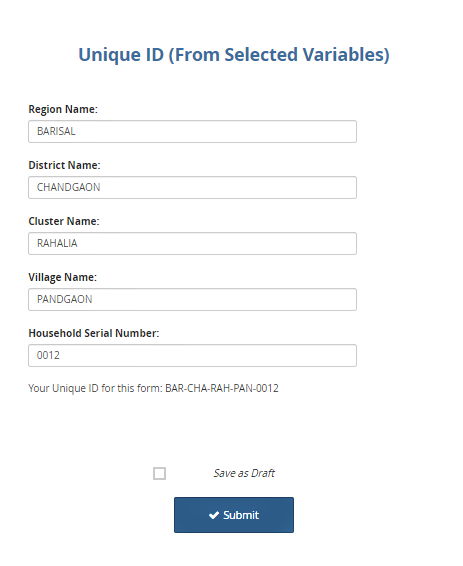

Designing Your Perfect New Serial Number Form Template: Tips and Best Practices

Creating an effective new serial number form template is about more than just listing fields; it’s about designing a tool that is intuitive, efficient, and fits seamlessly into your existing workflows. The goal is to make the data entry process as quick and error-free as possible, whether your team is working on a production line, in a warehouse, or in a retail environment. A well-designed form encourages accurate input and reduces the chances of critical information being overlooked or mistyped.

Consider the user experience. Will the form be filled out digitally or manually? For digital forms, think about dropdown menus for common entries, date pickers, and automated validation rules to minimize errors. For physical forms, ensure clear, legible fields with ample space for writing. The layout should flow logically, guiding the user from one piece of information to the next without confusion. Simple, clear labels are always better than ambiguous abbreviations.

One of the best practices is to keep it focused. While it’s tempting to include every possible data point, an overly complex form can become cumbersome and lead to user fatigue. Prioritize the essential information required for tracking and management, and consider creating separate forms or sections for less frequently needed details. This keeps the primary serial number entry process lean and efficient.

Remember to test your form. Before rolling out your new serial number form template across your organization, have a few team members from different departments fill it out. Gather their feedback and make adjustments as needed. This iterative process ensures the form is practical, user-friendly, and meets the real-world needs of your operations. An easily adoptable form is key to successful implementation and consistent data collection.

Ultimately, the best templates are those that evolve with your business. As your product lines change or your tracking needs grow, be prepared to revisit and refine your form. Regular reviews ensure it remains a valuable asset in your operations, continuously supporting accurate record-keeping and contributing to the overall efficiency of your business. This commitment to an optimized template will pay dividends in managing your inventory and ensuring product traceability.

Having a meticulously designed system for logging serial numbers is more than just good practice; it’s a strategic advantage. It empowers your team with accurate data, enhances your ability to manage inventory, streamline warranty processes, and respond swiftly to any product-related queries or issues. The precision and peace of mind that come from knowing every item is properly documented cannot be overstated.

By implementing a well-structured new serial number form template, you’re not just organizing numbers; you’re building a foundation for robust operational efficiency and superior customer satisfaction. Embrace the power of systematic data capture, and watch as your inventory management, customer support, and overall business operations become remarkably smoother and more reliable.