Bringing a new supplier on board is a significant step for any business, whether you’re sourcing raw materials, services, or finished goods. It’s a decision that can profoundly impact your product quality, operational efficiency, and even your bottom line. Without a clear, systematic way to assess potential partners, you’re essentially walking into a relationship blind, relying purely on instinct or a few quick phone calls. This informal approach often leads to unforeseen issues down the line, from delayed shipments and inconsistent quality to communication breakdowns and unexpected cost increases.

That’s where a structured approach becomes not just helpful, but essential. Imagine having a comprehensive checklist that guides you through every critical aspect of a potential supplier’s capabilities, financial health, and reliability. This is precisely what a well-designed new supplier evaluation form template offers. It standardizes your assessment process, ensures you ask all the right questions, and allows for objective comparison between different vendors, paving the way for more informed and confident procurement decisions that truly benefit your organization.

Why a Solid Supplier Evaluation is Non-Negotiable

In today’s fast-paced business world, your supply chain is only as strong as its weakest link. Relying on unvetted suppliers can expose your company to a myriad of risks. Think about it: a supplier with financial instability might suddenly cease operations, leaving you without critical components. A vendor with lax quality control could send you defective goods, damaging your reputation and costing you expensive recalls. Poor communication can lead to misunderstandings, missed deadlines, and a general erosion of trust that hinders your operations. These aren’t just minor inconveniences; they can translate into significant financial losses and operational headaches.

A structured supplier evaluation process, guided by a robust form, acts as your first line of defense. It forces you to look beyond the sales pitch and delve into the hard facts and figures that truly matter. By methodically assessing key areas, you can identify potential red flags early on, before they escalate into costly problems. This proactive approach saves you time, money, and a lot of stress in the long run. It’s about setting clear expectations from the outset and ensuring that any new partnership is built on a foundation of transparency and mutual understanding.

Furthermore, a consistent evaluation methodology ensures fairness and objectivity. Everyone involved in the procurement process uses the same criteria, reducing bias and ensuring that decisions are based on data rather than gut feelings. This not only leads to better supplier choices but also streamlines your internal processes, making them more efficient and scalable as your business grows. It fosters a culture of due diligence, ensuring that every new supplier earns their place in your network through demonstrated capability and reliability.

Key Areas to Assess

- Financial Stability: Are they solvent and reliable? Do they have a good credit history?

- Quality Management Systems: What processes do they have in place to ensure product or service quality?

- Production and Delivery Capabilities: Can they meet your volume requirements and deadlines consistently?

- Technical Competence: Do they possess the necessary expertise and technology for your specific needs?

- Communication and Responsiveness: How easy are they to work with? Are they proactive in their communication?

- Compliance and Ethical Practices: Do they adhere to all relevant regulations and ethical standards?

- Customer Service and Support: What kind of post-sale support can you expect?

By diligently reviewing these aspects, you gain a holistic view of a potential supplier’s strengths and weaknesses. It’s not just about finding someone who can deliver, but someone who can deliver consistently, reliably, and in alignment with your company’s values and standards. This comprehensive understanding empowers you to make strategic decisions that support your business objectives and mitigate risks effectively.

Crafting Your Perfect New Supplier Evaluation Form Template

While the core objective of any supplier evaluation is similar across industries, the specifics of your new supplier evaluation form template will ideally be tailored to your unique business needs. There’s no one-size-fits-all solution, but certain elements are universally beneficial. Start by identifying the most critical factors for your specific products or services. For instance, if you’re sourcing highly specialized components, technical capability might carry more weight than for a general office supply vendor. Think about what truly matters for your operations and risks.

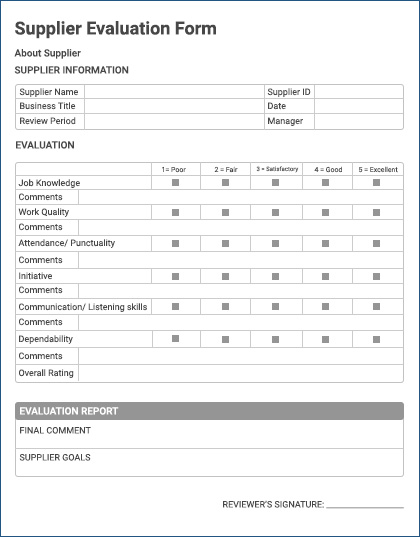

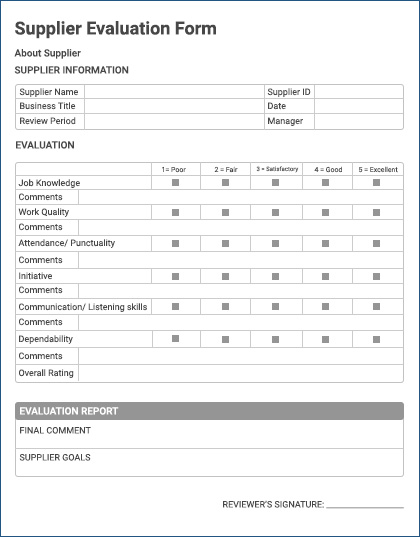

A good template will typically include sections for basic supplier information, a comprehensive checklist of evaluation criteria, a scoring mechanism, and space for comments or action items. The scoring mechanism is particularly important as it allows for quantifiable comparison. You might use a simple scale of 1-5, or a more detailed system where different criteria are weighted based on their importance to your business. The goal is to provide a clear, objective way to rate each supplier against your defined standards, making it easier to compare candidates side-by-side.

Remember, the form itself is a tool, but its effectiveness depends on how it’s used. It should be a living document that you review and update periodically to ensure it remains relevant to your evolving business needs and market conditions. As your company grows or as industry standards change, your evaluation criteria may need to adapt. Regular calibration of your evaluation process ensures that you’re always making the best possible choices for your supply chain, keeping it resilient and competitive.

Finally, consider involving a cross-functional team in the evaluation process. Procurement, quality control, production, and even finance can offer unique perspectives that enrich the assessment. Their collective input ensures a more thorough review and fosters buy-in for the final decision. Once a new supplier is selected, the evaluation form can also serve as a baseline for future performance monitoring, allowing you to track their ongoing performance against initial expectations and identify areas for improvement or further collaboration as the partnership evolves.

Adopting a meticulous approach to new supplier evaluation isn’t just about avoiding problems; it’s about building strong, reliable relationships that contribute directly to your company’s success. By investing time upfront in a comprehensive assessment process, you lay the groundwork for a robust and resilient supply chain. This proactive strategy ensures that every supplier you bring on board is a strategic asset, contributing positively to your operational efficiency and overall business growth.

Ultimately, the objective is to cultivate a network of trusted partners who can consistently meet your demands and contribute to your competitive advantage. A well-executed evaluation process, supported by a thoughtfully designed form, is your best tool for achieving this. It empowers you to make data-driven decisions, mitigate risks, and foster long-term collaborations that are beneficial for all parties involved, securing your supply chain’s future for years to come.