Utilizing a predefined structure for planning plumbing projects provides several key advantages. It promotes clear communication among stakeholders, facilitates accurate cost estimation and resource allocation, and aids in complying with regulatory requirements. Furthermore, a well-defined plan enhances on-site efficiency, minimizes errors, and improves overall project success rates by offering a roadmap for every stage of the process, from initial assessment to final inspection.

The following sections will delve deeper into the key components and practical applications of these structured plans within the plumbing industry, examining their role in ensuring project safety, quality control, and regulatory compliance.

1. Scope Definition

Accurate scope definition forms the foundation of a successful plumbing project. A clearly defined scope, within the context of a structured plan, ensures all stakeholders understand the project’s boundaries, preventing misunderstandings and costly revisions later. It provides a framework for all subsequent planning and execution activities.

- Project Boundaries:Precisely defining the physical boundaries of the plumbing work is crucial. This includes identifying specific areas within a building or property where work will be conducted, such as bathrooms, kitchens, or external pipe systems. For example, a renovation project might specify plumbing work limited to the second floor, excluding the ground floor and basement. Clear boundaries prevent scope creep and ensure accurate resource allocation.

- Specific Tasks:Listing all plumbing tasks within the project scope ensures comprehensive planning. This includes tasks like installing new fixtures, repairing existing systems, or rerouting pipes. A project involving bathroom renovation might list tasks like installing a new shower, toilet, sink, and connecting related plumbing lines. Detailed task identification facilitates accurate material estimation and scheduling.

- Exclusions:Clearly stating what the project does not include is equally important. This prevents assumptions and potential disputes. For example, a scope might exclude the installation of appliances connected to the plumbing system, such as dishwashers or washing machines. Defining exclusions ensures focus on the core plumbing tasks and manages client expectations.

- Acceptance Criteria:Defining the criteria for successful project completion is essential. This includes performance standards, quality checks, and inspection requirements. For example, a project might specify pressure testing all new pipework to ensure leak-free operation. Clear acceptance criteria provide a measurable benchmark for project completion and client satisfaction.

A well-defined scope within a structured plumbing plan acts as a roadmap for the entire project lifecycle. It ensures that everyone involved understands the objectives, deliverables, and limitations, contributing significantly to project success. This clarity minimizes the risk of misunderstandings, cost overruns, and delays, ensuring efficient and effective project delivery.

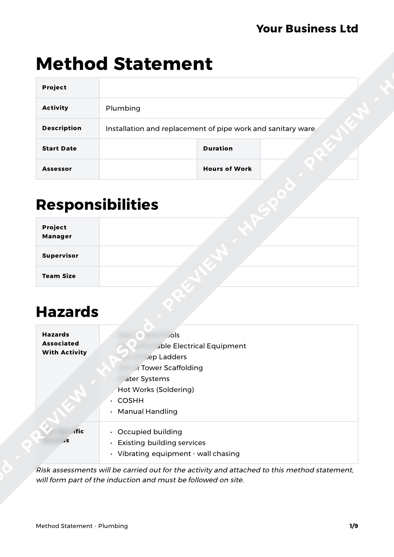

2. Hazard Identification

Proactive hazard identification is paramount within a structured plumbing plan. This process anticipates potential dangers associated with each task, ensuring worker safety and regulatory compliance. Identifying hazards before they materialize allows for implementing preventive measures, mitigating risks, and fostering a secure work environment.

- Working at Heights:Plumbing work often involves tasks performed at elevated levels, posing risks of falls. Whether working on rooftops, scaffolding, or ladders, a structured plan must identify these hazards. Fall protection measures, such as harnesses, safety nets, and edge protection, should be detailed, alongside procedures for safe ladder use and scaffold erection. This ensures worker safety and compliance with relevant height safety regulations.

- Confined Spaces:Plumbing tasks occasionally require entering confined spaces, such as crawl spaces or trenches. These areas can present unique hazards, including limited ventilation, the presence of hazardous gases, and difficult access/egress. A comprehensive plan identifies these risks and specifies appropriate controls, such as atmospheric monitoring, ventilation systems, and rescue procedures. These precautions are vital for worker well-being and project safety.

- Hot Work:Tasks involving soldering, welding, or cutting pipes introduce the risk of fire and burns. A robust plan addresses these hazards by specifying fire-resistant clothing, fire extinguishers, and designated hot work areas. Control measures, such as isolating flammable materials and implementing strict permit-to-work systems, are essential to prevent accidents. These steps minimize fire hazards and ensure a safe operational environment.

- Exposure to Hazardous Substances:Plumbers often work with materials containing chemicals or substances potentially harmful through inhalation, ingestion, or skin contact. A structured plan identifies these substances, requiring appropriate personal protective equipment (PPE), such as gloves, respirators, and eye protection. Safe handling procedures and emergency protocols for spills or leaks must be clearly defined, ensuring worker health and environmental protection.

Thorough hazard identification forms the bedrock of a safe and compliant plumbing project. By meticulously identifying and addressing potential dangers within the structured plan, risks are minimized, worker safety is enhanced, and projects proceed with greater confidence. This proactive approach not only protects personnel but also demonstrates a commitment to regulatory compliance and industry best practices.

3. Control Measures

Control measures represent a critical component within a plumbing method statement template. They provide the necessary framework for mitigating identified hazards, ensuring worker safety and project compliance. A direct correlation exists between the comprehensiveness of these controls and the overall effectiveness of the method statement. Without clearly defined and implemented control measures, a project remains vulnerable to accidents, delays, and regulatory breaches.

For instance, when working at heights, the method statement might specify the use of scaffolding. The control measures would then detail the scaffolding’s erection, inspection, and safe usage procedures. These might include requirements for trained scaffolders, load limits, guardrails, and regular inspections. Similarly, for hot work, control measures might mandate a permit-to-work system, specifying the necessary precautions before commencing any hot work activity. This could involve isolating flammable materials, providing fire extinguishers, and designating a fire watch.

The practical significance of incorporating detailed control measures within the method statement is substantial. It translates directly into enhanced on-site safety, reduced risk of accidents, and improved project efficiency. Well-defined control measures also facilitate compliance with relevant health and safety regulations, minimizing the potential for legal issues and project disruptions. By outlining specific actions and responsibilities, these measures promote a proactive safety culture, ensuring that potential hazards are addressed before they escalate into incidents. This, in turn, contributes to a smoother project execution, protecting both personnel and the overall project timeline.

4. Material Specifications

Precise material specifications are integral to a comprehensive plumbing method statement. Appropriate material selection directly impacts the quality, durability, and safety of the plumbing system. Clearly defined specifications ensure compatibility, prevent costly rework, and contribute to long-term system performance. Omitting or inadequately specifying materials can lead to project delays, substandard installations, and potential failures.

- Pipe Material and Sizing:Specifying the correct pipe material, such as copper, PVC, or CPVC, is crucial, considering factors like water pressure, temperature, and application. Incorrect material selection can lead to premature failure, leaks, or contamination. Similarly, specifying accurate pipe sizes ensures adequate water flow and pressure. Undersized pipes restrict flow, while oversized pipes increase material costs unnecessarily. A method statement must clearly define pipe material and sizing for each section of the plumbing system, referencing relevant industry standards.

- Fixture and Fitting Specifications:Detailed specifications for fixtures, including sinks, toilets, showers, and faucets, are essential. This includes manufacturer, model number, material composition, and performance characteristics. Specifications ensure compatibility with the overall plumbing system and meet client requirements for aesthetics and functionality. For example, specifying a low-flow toilet contributes to water conservation goals. Clear fixture and fitting specifications prevent compatibility issues and ensure the intended quality and performance.

- Valve and Control Specifications:Valves and controls play a critical role in regulating water flow and pressure within a plumbing system. Specifications must detail valve types, such as gate valves, ball valves, or check valves, along with their pressure ratings and material compatibility. Specifying appropriate valves ensures reliable system operation, facilitates maintenance, and prevents potential leaks or failures. This level of detail contributes to long-term system reliability and safety.

- Sealant and Joint Compound Requirements:Proper sealing is essential for preventing leaks and ensuring the integrity of plumbing connections. The method statement should specify approved sealants and joint compounds, considering factors like material compatibility, temperature resistance, and pressure requirements. Using incorrect sealants can lead to leaks, corrosion, or joint failure. Clear specifications for these materials contribute to the overall durability and reliability of the plumbing system.

Comprehensive material specifications are indispensable for a robust plumbing method statement. They ensure that all components of the plumbing system are fit for purpose, compatible with each other, and meet the required performance standards. This meticulous approach minimizes the risk of material-related issues, ensuring a durable, reliable, and safe plumbing installation. By providing clear guidance on material selection, the method statement contributes significantly to successful project completion and long-term client satisfaction.

5. Installation Procedures

Detailed installation procedures form the core of a plumbing method statement template. These procedures provide a step-by-step guide for executing the plumbing work, ensuring consistency, quality, and adherence to best practices. Well-defined installation procedures minimize the risk of errors, rework, and potential hazards. Their absence or inadequate detail can lead to project delays, compromised quality, and safety concerns.

- Pipe Installation:Procedures for pipe installation must specify the methods for cutting, joining, and supporting pipes. This includes details on soldering techniques, solvent welding procedures, and the use of appropriate hangers and supports. For example, when joining copper pipes, the procedure might specify cleaning procedures, flux application, and heating techniques to ensure a leak-proof joint. Clear instructions for pipe installation ensure consistent quality and prevent leaks or structural weaknesses.

- Fixture and Equipment Installation:Installing fixtures like sinks, toilets, and water heaters requires specific procedures to ensure proper functionality and prevent leaks. These procedures detail connection methods, mounting procedures, and required clearances. For instance, installing a toilet involves specifying the correct wax ring installation, securing the toilet to the floor, and connecting the water supply line. Detailed procedures ensure proper fixture installation and prevent future problems.

- Testing and Commissioning:Procedures for testing the completed plumbing system are critical for verifying proper operation and identifying potential leaks. This includes pressure testing, leak testing, and flushing procedures. For example, a pressure test involves filling the system with water and pressurizing it to a specified level to check for leaks. Documented testing procedures ensure system integrity and prevent future issues.

- Inspection and Handover:Procedures for final inspection and handover ensure that the completed work meets the specified requirements and is ready for client use. This includes visual inspections, functional tests, and documentation of completed work. A clear handover process ensures client satisfaction and provides a record of completed work for future reference. This final step confirms project completion and facilitates a smooth transition to client use.

Comprehensive installation procedures within a plumbing method statement template are crucial for successful project execution. They provide a roadmap for each stage of the installation process, ensuring quality, consistency, and safety. By outlining specific steps and techniques, these procedures minimize the risk of errors, rework, and potential hazards, ultimately contributing to a successful and compliant plumbing installation.

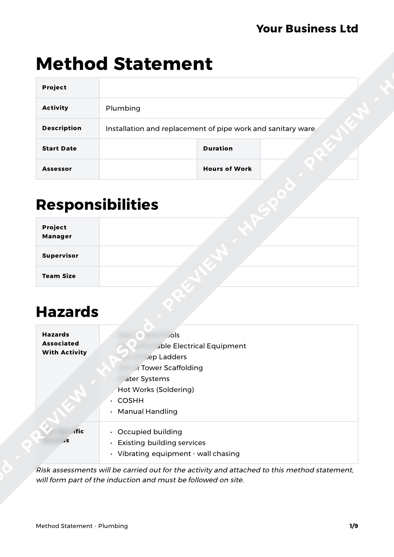

Key Components of a Plumbing Method Statement

A comprehensive plumbing method statement requires several key components to ensure clarity, safety, and effective project execution. These components provide a structured framework for planning and implementing plumbing work, minimizing risks and ensuring compliance with industry best practices.

1. Project Information: This section identifies the project, client, location, and relevant dates. Clear project information ensures all stakeholders are aware of the project scope and timeline, facilitating communication and coordination.

2. Scope of Work: A detailed description of the plumbing work to be performed, including specific tasks, materials, and equipment. A well-defined scope prevents misunderstandings and ensures accurate resource allocation.

3. Hazard Identification and Risk Assessment: This crucial component identifies potential hazards associated with the plumbing work and assesses the associated risks. This proactive approach allows for implementing appropriate control measures to mitigate potential dangers.

4. Control Measures: Specific measures implemented to mitigate identified hazards. These measures ensure worker safety and protect against potential accidents or incidents. Control measures might include using personal protective equipment (PPE), implementing safe work practices, and providing necessary training.

5. Resources: A list of personnel, equipment, and materials required for the project. Accurate resource allocation ensures efficient project execution and prevents delays due to shortages or inadequate equipment.

6. Installation Procedures: Step-by-step instructions for carrying out the plumbing work. Detailed procedures ensure consistency, quality, and adherence to best practices. These procedures should cover all aspects of the installation process, from pipe cutting and joining to fixture installation and testing.

7. Quality Control: Measures taken to ensure the quality of the plumbing work. This includes inspections, testing, and documentation. Robust quality control procedures ensure the finished work meets the required standards and client expectations.

8. Environmental Considerations: Addressing potential environmental impacts of the plumbing work, such as waste disposal and water conservation. This component demonstrates a commitment to environmental responsibility and compliance with relevant regulations.

A well-structured method statement, encompassing these key components, facilitates clear communication, promotes safe work practices, and ensures high-quality plumbing installations. This structured approach contributes to successful project completion, client satisfaction, and compliance with industry standards.

How to Create a Plumbing Method Statement Template

Creating a robust plumbing method statement template requires a systematic approach, ensuring all essential elements are incorporated. A well-structured template facilitates clear communication, promotes safe work practices, and guides consistent, high-quality plumbing installations.

1. Define the Scope: Begin by clearly defining the project scope. This includes specifying the types of plumbing work covered by the template, such as residential, commercial, or industrial installations. Defining the scope ensures the template remains relevant and applicable to the intended projects.

2. Identify Key Components: Outline the essential sections within the template. These typically include project information, scope of work, hazard identification, control measures, resources, installation procedures, quality control, and environmental considerations. A consistent structure facilitates easy navigation and comprehension.

3. Develop Detailed Procedures: Provide step-by-step instructions for each plumbing task covered by the template. These procedures should be clear, concise, and easy to follow, minimizing the risk of errors or misinterpretations. Include diagrams or illustrations where necessary to enhance clarity.

4. Incorporate Hazard Identification and Control Measures: Identify potential hazards associated with each plumbing task and specify appropriate control measures. This proactive approach ensures worker safety and minimizes the risk of accidents or incidents. Clearly outline safety precautions and required personal protective equipment (PPE).

5. Specify Material and Equipment Requirements: Detail the necessary materials and equipment for each task, including specifications, quantities, and quality standards. This ensures appropriate material selection and prevents compatibility issues or delays due to shortages.

6. Include Quality Control Checklists: Develop checklists to ensure adherence to quality standards throughout the plumbing process. These checklists should cover key inspection points, testing procedures, and documentation requirements. This ensures consistent quality and facilitates compliance with regulations.

7. Implement Version Control: Establish a version control system for the template to track revisions and updates. This ensures all users are working with the most current version and facilitates continuous improvement of the template.

8. Training and Communication: Provide training to all personnel using the template to ensure proper understanding and application. Regular communication and feedback mechanisms facilitate continuous improvement and ensure the template remains a valuable tool for plumbing projects. This fosters a culture of safety and quality within the organization.

A comprehensive plumbing method statement template provides a crucial framework for safe, efficient, and high-quality plumbing installations. By incorporating these key elements, organizations can standardize procedures, mitigate risks, and ensure consistent project delivery.

Structured planning, as embodied in a plumbing method statement template, provides a critical framework for executing plumbing projects safely, efficiently, and to a high standard. From defining the scope and identifying potential hazards to specifying materials and outlining detailed installation procedures, the template serves as a roadmap for every stage of the project lifecycle. Rigorous attention to control measures, quality control processes, and environmental considerations ensures compliance with regulations and best practices. Such meticulous planning minimizes risks, enhances communication among stakeholders, and ultimately contributes to successful project outcomes.

The consistent application of these structured plans elevates professionalism within the plumbing industry. It fosters a proactive safety culture, reduces the likelihood of errors and rework, and promotes client satisfaction through predictable, high-quality results. Embracing structured planning is not merely a best practice; it represents a commitment to excellence and continuous improvement within the plumbing trade.