Operating powered industrial trucks, often simply called forklifts, is a critical part of many industries, from manufacturing plants to warehouses and construction sites. These powerful machines significantly boost productivity, but they also come with inherent risks if not properly maintained and inspected. Ensuring the safety of your operators and the longevity of your equipment isn’t just a good practice; it’s a fundamental requirement for a secure and efficient workplace.

That’s where a robust inspection process comes into play. Regular checks help identify potential issues before they escalate into major problems, leading to costly repairs, operational downtime, or worse, serious accidents. Having a standardized and easy-to-use system for these inspections is absolutely essential, and that’s precisely where a well-designed template proves invaluable.

Why a Powered Industrial Truck Inspection Form Template is Non-Negotiable

Implementing a reliable inspection routine for your powered industrial trucks isn’t just about ticking boxes; it’s a cornerstone of workplace safety and operational efficiency. Without a structured approach, critical maintenance points can easily be overlooked, leading to breakdowns and even tragic accidents. A comprehensive inspection form template provides a consistent checklist, ensuring that no vital component or safety feature is missed during the daily or shift-based checks. This level of diligence protects your valuable equipment and, more importantly, the lives of your employees.

Beyond immediate safety, a standardized inspection process contributes significantly to compliance with regulatory bodies like OSHA (Occupational Safety and Health Administration). These organizations have stringent requirements for the safe operation and maintenance of industrial equipment. Failing to meet these standards can result in hefty fines, legal liabilities, and damage to your company’s reputation. A detailed powered industrial truck inspection form template serves as clear documentation that your organization is proactive in meeting these obligations, providing an auditable trail of due diligence.

Moreover, regular inspections documented through a template help extend the lifespan of your industrial trucks. By catching minor issues like worn tires, loose connections, or fluid leaks early on, you can schedule preventative maintenance rather than reactive repairs. This proactive approach minimizes unexpected downtime, reduces maintenance costs over time, and ensures that your equipment remains in optimal working condition. It’s an investment in the longevity and reliability of your fleet, preventing minor wear from escalating into major, expensive failures.

Finally, integrating a well-designed powered industrial truck inspection form template fosters a culture of safety among operators and management alike. When operators are responsible for completing a daily checklist, they become more attuned to the condition of their equipment and more mindful of safe operating practices. It empowers them to identify and report issues, feeling assured that their concerns will be addressed. This shared responsibility for safety creates a more vigilant and accountable workforce, ultimately leading to a safer and more productive environment for everyone.

Ensuring OSHA Compliance and Workplace Safety

- Identify potential mechanical failures before operation.

- Ensure all safety features (lights, horn, seatbelt) are functional.

- Maintain records for regulatory compliance and audits.

- Promote operator accountability and awareness.

- Reduce the risk of accidents, injuries, and fatalities.

What to Look For in a Comprehensive Inspection Form Template

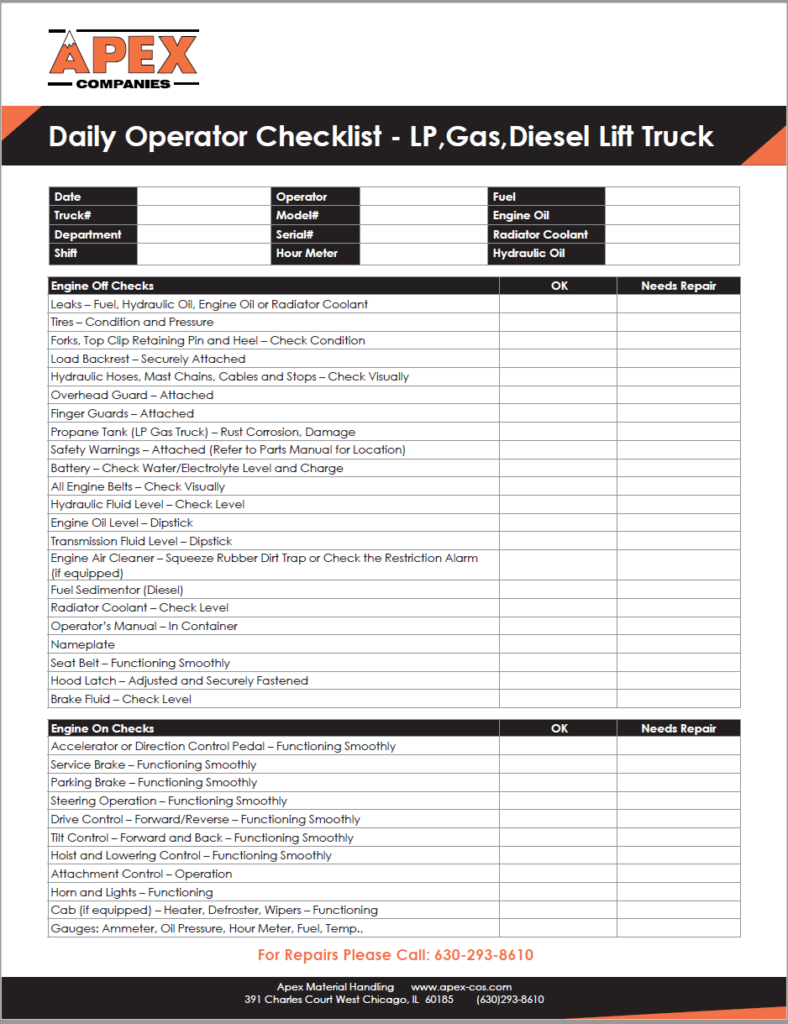

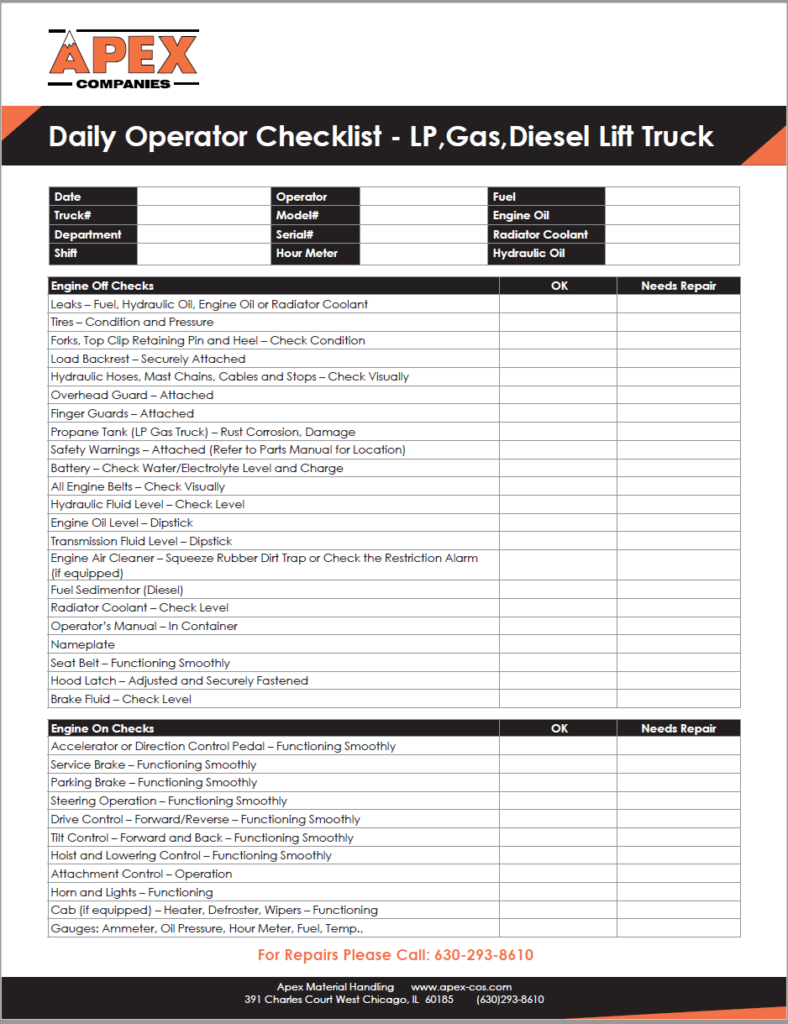

When selecting or creating a powered industrial truck inspection form template, it’s crucial to ensure it covers all necessary checks to maintain safety and operational integrity. A truly effective template should break down the inspection into logical, easy-to-follow sections. This typically starts with pre-operational checks, which an operator performs before each shift, including items like tire condition, fluid levels, and the functionality of lights and horns. These initial checks are vital because they can prevent many accidents before the truck even leaves the charging station or parking area.

Moving beyond the initial visual checks, a good template will then delve into operational performance. This includes testing the steering, brakes, and control levers to ensure they respond correctly and smoothly. The mast and fork mechanisms—their lifting, lowering, tilting, and side-shifting capabilities—must be thoroughly checked for any signs of sluggishness, unusual noises, or hydraulic leaks. These operational checks are critical for verifying that the truck can perform its tasks safely and efficiently under load, which is often when underlying issues become apparent.

Furthermore, a comprehensive inspection form template should include sections for different types of powered industrial trucks, acknowledging that a forklift’s specific components might differ from a pallet jack or an order picker. It should also have a clear system for indicating whether an item “passes” or “fails,” along with space for comments on any identified issues. This allows operators to report concerns clearly and concisely, flagging equipment that needs immediate attention from maintenance personnel.

Lastly, don’t overlook the importance of administrative details within the template. Space for the date, time, operator’s name, truck ID number, and supervisor’s signature is essential for record-keeping and accountability. A well-designed template makes it easy to track inspections over time, identify recurring issues with specific vehicles, and demonstrate a consistent commitment to safety and maintenance. The goal is to create a living document that guides preventative action and contributes to a safer, more productive operation.

- Pre-operation checks (visual inspection of tires, forks, overhead guard, etc.).

- Fluid levels and leaks (oil, hydraulic, coolant).

- Operational checks (brakes, steering, controls, lights, horn, battery).

- Mast and hydraulic system functionality.

- Emergency stop button and safety interlocks.

- Clear sections for ‘Pass’ or ‘Fail’ and ‘Comments’.

- Space for date, truck ID, operator signature, and supervisor sign-off.

Ensuring the regular and thorough inspection of your powered industrial trucks is not just a regulatory obligation; it’s a critical component of maintaining a safe, efficient, and productive workplace. By utilizing a comprehensive and easy-to-follow form, you empower your operators to be the first line of defense against potential hazards, catching minor issues before they escalate into major problems. This proactive approach minimizes downtime, extends equipment life, and most importantly, protects your most valuable asset: your people.

Investing time in developing or adopting the right template for your operations is a small effort that yields significant returns in terms of safety, compliance, and operational continuity. A well-documented inspection process provides peace of mind, knowing that your fleet is in optimal condition and your team is working in the safest possible environment.