In the complex landscape of industrial operations, where minute changes can have significant safety implications, maintaining vigilance is not just a best practice, but a critical imperative. Ensuring that every modification, whether to equipment, procedures, raw materials, or even personnel, is thoroughly reviewed before implementation is fundamental to preventing incidents. This proactive approach is embodied in the principle of Management of Change, a cornerstone of process safety. A well-designed form acts as the backbone of this crucial process, guiding teams through necessary assessments and approvals.

Implementing a robust Management of Change (MOC) system is essential for any facility dealing with hazardous processes. It is more than just a regulatory requirement; it is a systematic method to manage risks associated with changes. Without a structured approach, seemingly minor alterations can inadvertently introduce new hazards or undermine existing safeguards. This is precisely why a comprehensive process safety management of change form template becomes an indispensable tool, ensuring that no stone is left unturned in the pursuit of operational safety and compliance.

Deconstructing the Anatomy of an Effective MOC Form

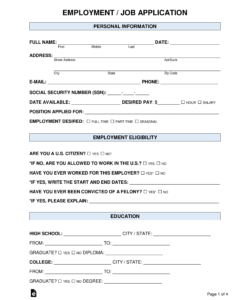

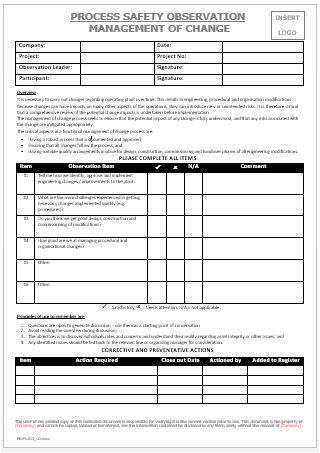

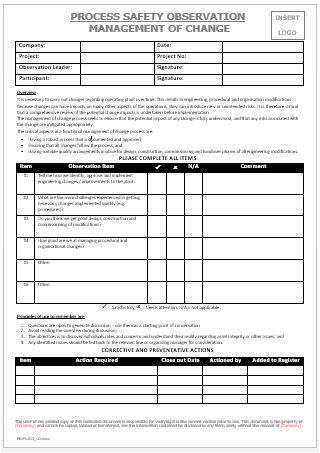

At its core, a Management of Change form is a structured document designed to capture all necessary information about a proposed change, facilitate its review, and track its approval and implementation. It serves as a single source of truth for the change, from its initiation to its completion. The purpose is not to hinder progress, but to ensure that changes are made safely, without introducing unintended consequences. This involves identifying potential hazards, evaluating risks, and putting controls in place before the change takes live.

The form plays a pivotal role in ensuring that all relevant stakeholders are involved in the review process. This includes operations, maintenance, engineering, health and safety, and even environmental departments, depending on the nature of the change. By requiring signatures and detailed justifications at various stages, the template enforces accountability and transparency. It helps create a historical record of all modifications, which is invaluable for audits, incident investigations, and continuous improvement initiatives.

Regulatory bodies, such as OSHA in the United States, mandate MOC programs for facilities handling highly hazardous chemicals. While they don’t prescribe a specific form, they outline the elements that must be considered. A well-thought-out process safety management of change form template directly addresses these requirements, simplifying compliance and demonstrating due diligence. It acts as a clear roadmap for anyone proposing or reviewing a change, making the complex process manageable and consistent across the organization.

Understanding the vital components of such a template is crucial for its effectiveness. Without the right fields and sections, even the most diligent team might overlook a critical step. A good template anticipates the information needed to make informed decisions about the safety implications of a change, guiding users through a systematic evaluation process.

Key Elements of a Comprehensive Process Safety Management of Change Form Template

- **Change Description and Justification:** Clearly outlining what the change is, where it will occur, and why it is necessary.

- **Technical Basis:** Providing supporting technical information, drawings, or specifications related to the change.

- **Hazard Review and Risk Assessment:** Identifying potential hazards introduced or affected by the change and evaluating associated risks. This often involves techniques like HAZOP or What-If analysis.

- **Impact on Safety Information:** Assessing how the change affects process safety information (e.g., P&IDs, operating procedures, training, emergency plans).

- **Pre-startup Safety Review (PSSR) Requirements:** Detailing any necessary pre-startup checks or verifications before the change can be brought online.

- **Authorization and Approvals:** Sections for various levels of management and technical experts to sign off on the change.

- **Training Needs:** Identifying who needs training on the new process or equipment.

- **Communication Plan:** Outlining how the change will be communicated to affected personnel.

- **Completion and Close-out:** A section to confirm that all MOC steps have been completed and the change is safely implemented.

Implementing and Optimizing Your MOC Form for Enhanced Safety

Having a well-designed process safety management of change form template is just the first step. The true value comes from its effective implementation and continuous optimization within the broader MOC system. It’s not merely a piece of paper or a digital document; it’s a living tool that facilitates critical thinking and collaborative decision-making. For the template to truly enhance safety, it must be integrated seamlessly into daily operations and supported by a culture that prioritizes thoroughness and caution.

Training is paramount. All employees, especially those who might initiate or be affected by a change, need to understand the MOC process and how to properly use the form. This includes not just filling it out, but understanding the underlying safety principles and the consequences of incomplete or rushed assessments. Regular refresher training ensures that the importance of the MOC process remains top-of-mind and that new hires are quickly brought up to speed.

Beyond training, the organization needs clear policies and procedures that define the scope of MOC, who is responsible for each step, and the timelines for review and approval. An effective MOC system includes a mechanism for tracking the status of changes, ensuring that no proposed modification falls through the cracks. This often involves digital MOC systems that can automate workflows, send notifications, and provide real-time dashboards of pending and completed changes, further bolstering the utility of the form itself.

Regular audits and reviews of the MOC process itself are crucial for continuous improvement. Are forms being filled out completely and accurately? Are reviews thorough? Are timelines being met? Are incidents occurring that could have been prevented by a more robust MOC? Learning from both successes and failures helps refine the process safety management of change form template and the surrounding system, ensuring it remains effective and relevant as operations evolve.

The goal is to foster a proactive safety culture where employees feel empowered to identify the need for an MOC and are confident in using the system. When a change is proposed, it should be met with questions, not immediate approval. “What could go wrong?” “What impact will this have on existing safeguards?” These are the questions an effective MOC form encourages, guiding users to thoroughly evaluate every aspect of a modification before it becomes a new operational reality.

The thoughtful application of a comprehensive process safety management of change form template is a testament to an organization’s commitment to safety excellence. It serves as a visible pledge to scrutinize every alteration, ensuring that operational efficiencies are never pursued at the expense of personnel well-being or environmental integrity. By embedding this systematic approach into daily operations, companies not only meet regulatory obligations but also cultivate a robust culture of safety that proactively prevents incidents and safeguards their most valuable assets.

Embracing and continuously refining your MOC process, anchored by a well-structured form, is an investment in long-term operational resilience. It ensures that every step forward is a safe one, building a legacy of responsible and secure industrial practices. This dedication to thoroughness and foresight lays the groundwork for sustained success in any hazardous environment.