In the world of manufacturing, quality isn’t just a buzzword; it’s the bedrock of reputation, customer satisfaction, and long-term success. Every single component that goes into a final product needs to meet stringent standards, and that’s where a robust inspection process comes into play. Without a clear, consistent method for checking parts, defects can slip through, leading to costly reworks, recalls, and a dent in your brand’s image. This is precisely why having a well-designed production part inspection form template isn’t just helpful, it’s absolutely essential for maintaining quality control and operational efficiency.

Think of it as your quality assurance blueprint. It provides a structured approach, ensuring that every critical aspect of a part is examined, documented, and approved before it moves to the next stage of production or shipment. By standardizing this process, you minimize human error, create a clear audit trail, and empower your team to consistently deliver high-quality output. It’s about being proactive rather than reactive when it comes to quality, catching issues early on, and ensuring everything is right the first time.

Why a Standardized Production Part Inspection Form is Crucial

Implementing a standardized production part inspection form brings a multitude of benefits that extend far beyond simply catching errors. Firstly, it ensures consistency across all inspections, regardless of who is performing them. This eliminates subjective interpretations and ensures that the same criteria are applied to every part, every time. Without this uniformity, you might find that defects that are caught by one inspector are missed by another, leading to an unpredictable quality output that can harm your reputation and bottom line. It establishes a baseline for expected quality and empowers your team to meet it.

Secondly, a well-structured form acts as a powerful tool for defect prevention and continuous improvement. When inspectors meticulously document their findings, you begin to accumulate valuable data. This data isn’t just for record-keeping; it’s a goldmine of insights. By analyzing recurring issues or common failure points noted on the forms, you can identify underlying problems in your manufacturing process, equipment, or even material sourcing. This allows you to address the root causes of defects, rather than just patching them up, leading to systemic improvements that enhance overall product quality.

Furthermore, these forms provide an undeniable level of accountability and traceability. Should a quality issue arise down the line, whether it’s days, weeks, or even months after production, your inspection forms offer a clear historical record. You can easily trace back to who inspected the part, when it was inspected, and what the findings were. This audit trail is invaluable for internal investigations, troubleshooting customer complaints, or demonstrating compliance with industry regulations and standards. It provides clear evidence of your commitment to quality at every step.

Finally, integrating a comprehensive inspection form into your workflow significantly reduces the likelihood of costly reworks, scrap, and warranty claims. Catching a defect at the inspection stage is infinitely cheaper and less disruptive than discovering it after assembly, or worse, after it has reached the customer. By preventing defective parts from progressing through your production line, you save on labor, materials, and potential logistical nightmares. This directly translates to improved profitability and a more efficient manufacturing operation.

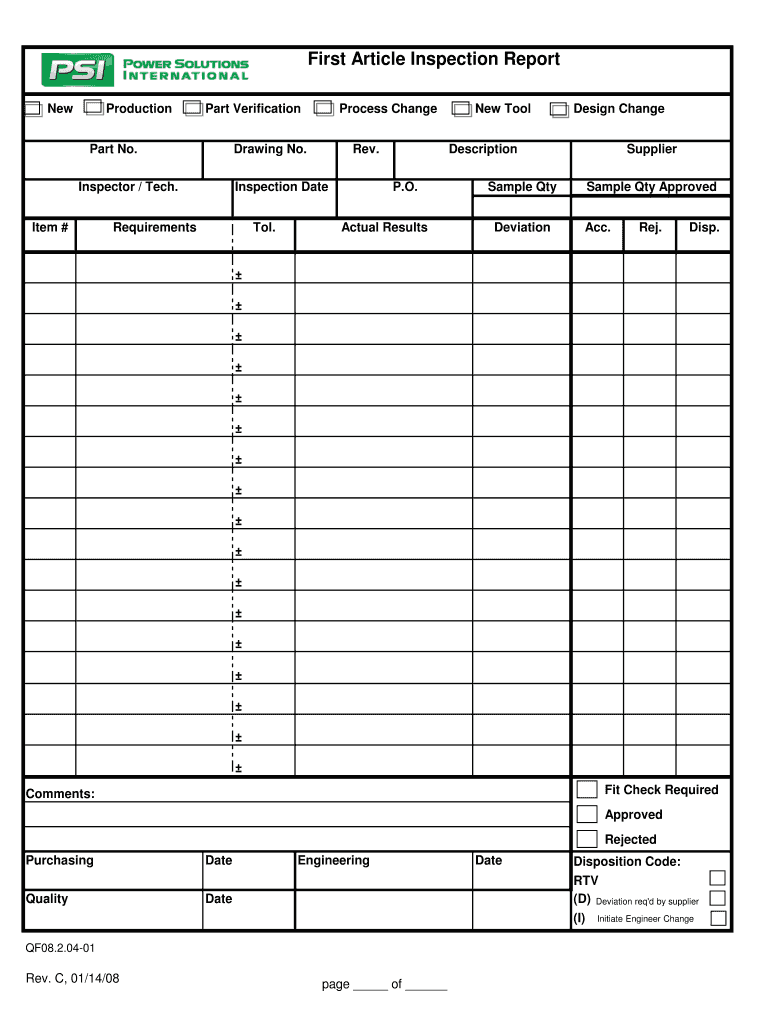

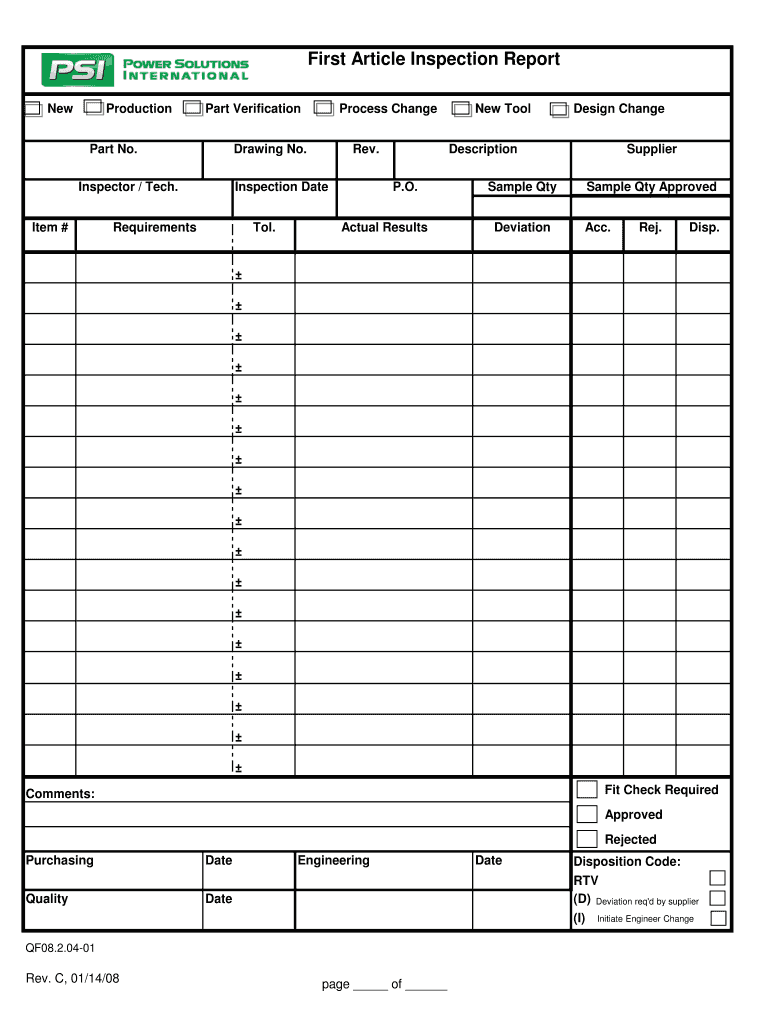

Key Elements to Include in Your Form

- Part Name and Number

- Date and Time of Inspection

- Inspector’s Name/ID

- Batch/Lot Number

- Quantity Inspected

- Acceptance Criteria/Tolerances

- Inspection Method Used (e.g., visual, caliper, gauge)

- Results (Pass/Fail/Hold) for each attribute

- Measurements Taken (if applicable)

- Description of Any Defects Found

- Corrective Actions Taken or Recommended

- Signature and Date of Approval/Review

Crafting Your Ideal Production Part Inspection Form

Designing the perfect production part inspection form requires a thoughtful approach, as it needs to be tailored to your specific products, processes, and industry requirements. While a generic template provides a great starting point, the real magic happens when you customize it to reflect the unique nuances of your operations. Consider the types of parts you produce, the critical characteristics that need to be checked, and the specific tools or gauges your inspectors will use. An overly complex form can be cumbersome, while one that’s too simplistic might miss crucial details. The goal is to strike a balance that ensures thoroughness without sacrificing efficiency.

When developing your form, think about the user experience for your inspectors. Is it easy to read? Are the fields clearly labeled? Can data be entered quickly and accurately? Whether you opt for a traditional paper-based form or a digital solution, clarity and ease of use are paramount. Digital forms, for instance, can offer benefits like automated data logging, photo attachments, and immediate reporting, which can significantly streamline your quality control process. However, even with digital tools, the underlying structure and content of your form remain the most important aspect.

It’s also crucial to involve your production and quality teams in the development process. They are the ones who will be using the form daily, and their insights are invaluable. They can highlight practical considerations, identify areas where common errors occur, and suggest improvements that make the form more effective and user-friendly. Training your team on how to properly use the new or revised form is equally important. Ensure they understand each field, the criteria for acceptance or rejection, and the importance of accurate documentation. Clear communication reduces ambiguity and ensures consistent application of the inspection standards.

Finally, remember that your production part inspection form isn’t a static document. As your products evolve, your processes change, or new quality standards emerge, your form should evolve too. Regularly review its effectiveness, gather feedback from your inspectors, and make necessary adjustments. This iterative approach ensures that your inspection process remains robust, relevant, and continually contributes to improving the quality of your manufactured parts. A dynamic, adaptable form is a hallmark of a mature and proactive quality management system.

By diligently implementing and continuously refining your quality control measures, supported by a meticulously designed form, you empower your team to maintain high standards across all stages of production. This proactive stance significantly reduces the risk of defects reaching the end customer, saving resources and bolstering your reputation in the marketplace.

Ultimately, a well-executed inspection strategy, underpinned by a clear and comprehensive form, becomes an indispensable asset in achieving operational excellence. It fosters a culture of quality, drives continuous improvement, and ensures that every part that leaves your facility meets or exceeds expectations, contributing directly to client satisfaction and sustained business growth.