In the world of manufacturing and production, things are always evolving. Whether it’s sourcing new suppliers, improving product performance, or simply adapting to market demands, changes to raw materials are a common occurrence. However, simply making a change isn’t enough; it’s how you manage and document that change that truly makes a difference to your operations and overall product quality.

That’s where a well-designed raw material change form template becomes an invaluable asset. It’s not just a piece of paper; it’s a crucial tool for ensuring consistency, maintaining quality, and providing a clear audit trail for every single modification. Think of it as your company’s memory for all raw material shifts, guaranteeing that everyone is on the same page and that changes are implemented smoothly and correctly.

Why a Raw Material Change Form is Indispensable for Your Operations

Imagine a scenario where a critical component for your product suddenly changes its composition without proper documentation. This could lead to production line disruptions, product failures, costly recalls, and even damage to your brand’s reputation. A standardized raw material change form template acts as a vital safeguard against such pitfalls, providing a structured approach to managing modifications before they cause headaches.

This systematic approach ensures that every change, no matter how minor it might seem, goes through a predefined review and approval process. It forces various departments—from purchasing and quality control to R&D and production—to communicate and collaborate effectively. This cross-functional alignment is essential for identifying potential impacts, mitigating risks, and ensuring that the new material is suitable for its intended use without compromising the final product.

Moreover, regulatory compliance is a significant factor in many industries. Demonstrating a robust change management process is often a requirement for certifications and audits. A clear, detailed form provides undeniable proof that changes are not haphazardly implemented but are carefully considered, documented, and approved according to established protocols. This transparency can save your business from hefty fines and legal troubles down the line.

Ultimately, a reliable form fosters a culture of accountability and continuous improvement within your organization. It transforms potential chaos into controlled progression, allowing your team to innovate and adapt with confidence. Every completed form contributes to a rich history of your materials, which can be invaluable for troubleshooting, process optimization, and future material selection.

Key Benefits of Using a Standardized Form

- Ensures comprehensive documentation of all changes.

- Facilitates clear communication across relevant departments.

- Reduces the risk of errors, quality issues, and production delays.

- Supports regulatory compliance and simplifies audits.

- Provides a historical record for future reference and analysis.

- Enhances decision-making processes regarding material sourcing.

Essential Elements of an Effective Raw Material Change Form Template

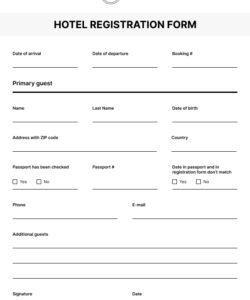

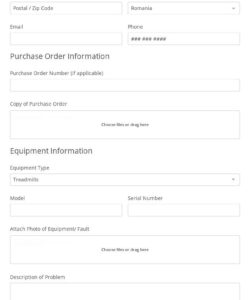

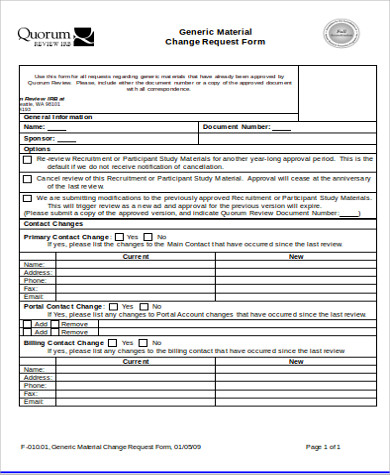

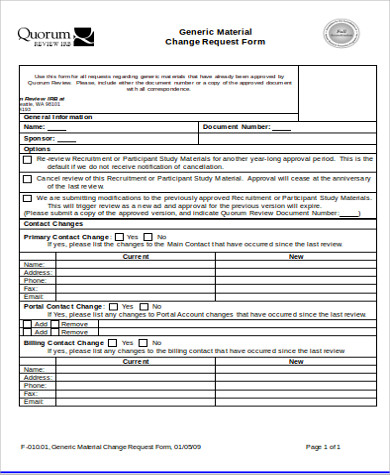

Crafting an effective raw material change form template requires careful consideration of all the information necessary to fully understand, approve, and implement a change. It’s not just about what you changed, but why, who approved it, and what the potential ripple effects might be. A good template should guide the user through a logical flow of information, ensuring no critical detail is overlooked.

At its core, the form should clearly identify the material in question, both the old specification and the proposed new one. This includes detailed descriptions, part numbers, supplier information, and any relevant technical specifications. Equally important is the reason for the change. Is it due to supplier discontinuation, cost reduction, quality improvement, or a regulatory mandate? Articulating the “why” helps in assessing the change’s strategic importance and urgency.

Furthermore, an effective template must include sections for impact assessment. How will this change affect production processes, product performance, packaging, shelf life, or even regulatory labeling? Capturing these potential impacts upfront allows teams to prepare for necessary adjustments and prevents unforeseen complications. This proactive approach is a hallmark of efficient change management.

Finally, a critical component of any change form is the approval workflow. Who needs to sign off on this change? Typically, this involves representatives from quality assurance, research and development, purchasing, and production. Their signatures or digital approvals signify that they have reviewed the change, understood its implications, and deemed it acceptable. Including an effective date for the change is also crucial for tracking and implementation purposes, making the raw material change form template a living document throughout its lifecycle.

By implementing a well-structured and comprehensive raw material change form, you empower your organization to manage material transitions with precision and confidence. It’s an investment in your product’s quality, your operational efficiency, and your company’s long-term success. This systematic approach transforms potential disruptions into well-managed evolutions, ensuring that every material change serves to strengthen your products and processes.

Embracing such a structured approach to raw material changes contributes significantly to overall operational excellence. It builds a foundation of reliability and accountability, allowing your teams to focus on innovation and improvement rather than reacting to unexpected issues. This proactive stance is what differentiates leading manufacturers from the rest.