In the world of asset management, facilities upkeep, or even managing your own home, you often hear the terms “repair” and “maintenance” thrown around interchangeably. However, these two concepts, while related, signify very distinct activities with different implications for costs, planning, and long-term asset health. Confusing them can lead to misallocated resources, unexpected downtime, and a general lack of clarity in operational processes.

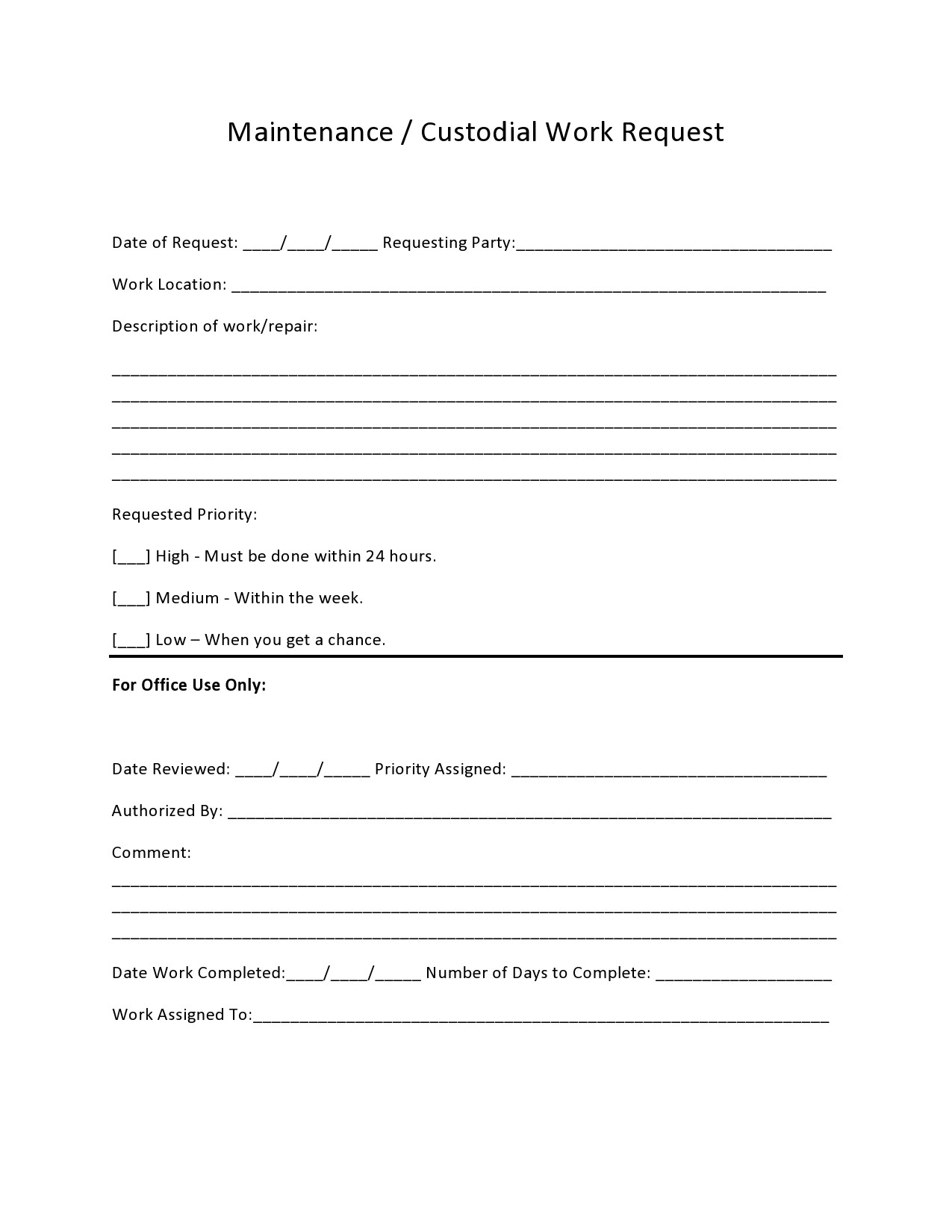

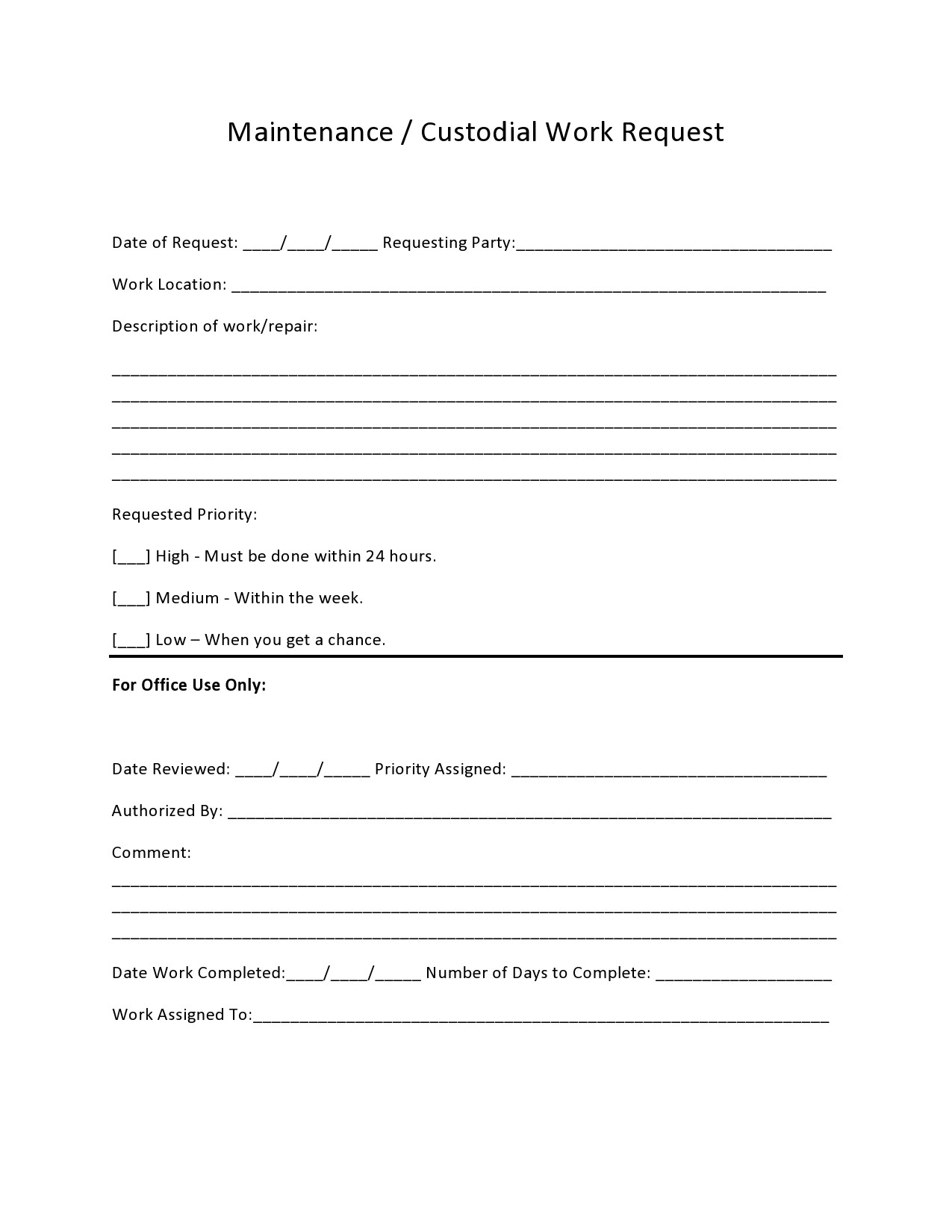

Unraveling this distinction is not just an academic exercise; it is a practical necessity for any organization or individual striving for efficiency and longevity of their equipment and infrastructure. Knowing whether an action is a preventive measure or a reactive fix helps in budgeting, scheduling, and even in communicating with service providers. That’s where a clear framework, like a dedicated form template, becomes incredibly useful, helping to categorize and track these vital activities with precision.

Understanding Maintenance: The Proactive Approach

Maintenance fundamentally refers to all the actions taken to keep an asset in good working order and prevent it from breaking down. It is inherently proactive, designed to preserve the functionality and extend the lifespan of equipment or property before a failure occurs. Think of it as regularly visiting the doctor for a check-up, even when you feel perfectly fine, to catch potential issues early or ensure your body is functioning optimally. This foresight is crucial for operational stability and long-term cost savings.

There are several types of maintenance, each with its own specific aim. Preventive maintenance involves scheduled inspections, servicing, and part replacements based on a fixed timetable or usage intervals. Predictive maintenance uses technology and data analytics to monitor the condition of equipment in real-time, allowing for interventions only when a potential failure is indicated. Routine maintenance includes everyday tasks like cleaning, lubrication, and minor adjustments that keep things running smoothly. Each type contributes to the overall goal of avoiding unexpected breakdowns.

The benefits of a robust maintenance program are extensive. It significantly reduces the likelihood of costly emergency repairs, extends the life of assets, improves safety, enhances operational efficiency, and helps in better budget forecasting. By consistently maintaining equipment, businesses can avoid disruptive downtime that directly impacts productivity and profitability. It is an investment in continuity rather than a reaction to crisis.

Ultimately, maintenance is about foresight and preservation. It’s about ensuring that a machine continues to perform its intended function without interruption, minimizing wear and tear, and optimizing its operational output over time. This ongoing care builds resilience into your systems, making them less susceptible to sudden failures and ensuring a smoother, more predictable operational flow.

Key Aspects of Effective Maintenance

- Scheduled Inspections: Regular checks to identify potential issues before they escalate.

- Preventive Replacements: Changing parts based on recommended lifespan, not just when they fail.

- Routine Servicing: Oiling, cleaning, and tuning to keep components in optimal condition.

- Condition Monitoring: Using sensors and data to predict when maintenance is truly needed.

Understanding Repair: The Reactive Response

In stark contrast to maintenance, repair is a reactive process undertaken when an asset has already failed, is damaged, or is no longer performing its intended function. It’s the act of restoring something broken back to its working condition. If maintenance is your regular doctor’s visit, repair is an emergency room visit after an accident. It addresses an immediate problem that has already manifested, aiming to fix the issue and bring the asset back online as quickly as possible.

Repairs often occur unexpectedly, leading to unplanned downtime and significant costs. The nature of a repair can vary widely, from replacing a failed component like a motor or a pipe burst, to fixing structural damage in a building or rectifying a software glitch that halts operations. The common thread is that something has gone wrong, and an intervention is required to correct the malfunction and restore functionality.

Because repairs are typically unplanned, they can be highly disruptive to operations. They often require immediate attention, possibly at inconvenient times, and can incur higher labor costs (e.g., overtime rates for emergency call-outs) and parts expenses. Furthermore, the lack of foresight in repairs means that the necessary parts or skilled personnel might not be readily available, leading to further delays and increased frustration. This contrasts sharply with maintenance, where resources can be planned well in advance.

While effective maintenance aims to minimize the need for repairs, some level of repair will always be necessary. Assets wear out, unexpected accidents happen, and parts eventually fail despite the best preventive efforts. The key is to reduce the frequency and severity of these reactive events through diligent maintenance practices. However, when a breakdown does occur, a clear process for identifying, documenting, and executing the repair is essential to minimize its impact.

Streamlining Operations with Clarity

Distinguishing between repair and maintenance is not merely about vocabulary; it is about establishing a clear operational strategy. Maintenance is about foresight, prevention, and sustained performance, ensuring continuity and extending asset life. Repair is about response, correction, and restoring functionality after a breakdown, often at a higher immediate cost and with more disruption. Understanding these distinct roles is paramount for efficient asset management, and a well-designed repair maintenance differences form template can serve as an invaluable tool in this endeavor.

By clearly documenting whether an activity is a scheduled maintenance task or an urgent repair, organizations can better allocate resources, manage budgets, track asset performance, and even comply with regulatory requirements. This clarity leads to improved operational efficiency, reduced downtime, and ultimately, a healthier bottom line. Embracing this distinction helps to build a more resilient and predictable operational environment, moving from reactive firefighting to proactive asset stewardship.