In the world of manufacturing and supply chain management, ensuring product quality and maintaining strong supplier relationships are paramount. Even with the best intentions, issues can arise, leading to non-conformances, defects, or delays. When these problems occur, a swift, clear, and structured response is not just helpful, it’s absolutely critical. This is where a well-designed supplier corrective action response form template becomes an indispensable tool for any quality-focused organization.

Imagine the confusion and lost time if every supplier communicated their corrective actions in a different format, or worse, not at all. A standardized template cuts through that chaos, providing a clear pathway for suppliers to document their understanding of the problem, the immediate actions taken, the root cause analysis performed, and the long-term corrective actions implemented to prevent recurrence. It’s about fostering accountability and a shared commitment to quality improvement, turning potential crises into opportunities for growth and stronger partnerships.

Why a Standardized Supplier Corrective Action Response Form is Essential

Think about the alternative: without a standardized form, you’d likely be sifting through emails, phone calls, and hastily scribbled notes trying to piece together a coherent picture of a quality issue. This fragmented approach is not only inefficient but also highly prone to miscommunication and overlooked details. A dedicated corrective action form brings structure, ensuring that all necessary information is captured consistently, making it easier for your team to review, verify, and track progress.

Beyond just organization, a standardized form promotes accountability. When a supplier knows exactly what information is required and how it needs to be presented, it encourages them to conduct a thorough investigation into the issue. It shifts the focus from merely fixing a problem to understanding why it happened and what systemic changes are needed to prevent its recurrence. This proactive approach is fundamental to continuous improvement within your supply chain.

Furthermore, these forms serve as a vital historical record. Over time, the data collected from completed forms can reveal patterns, highlight recurring issues with specific suppliers or processes, and inform strategic decisions about supplier development or even qualification. It’s not just about addressing the immediate problem; it’s about building a robust knowledge base that fuels long-term quality enhancement and risk mitigation across your entire supply network.

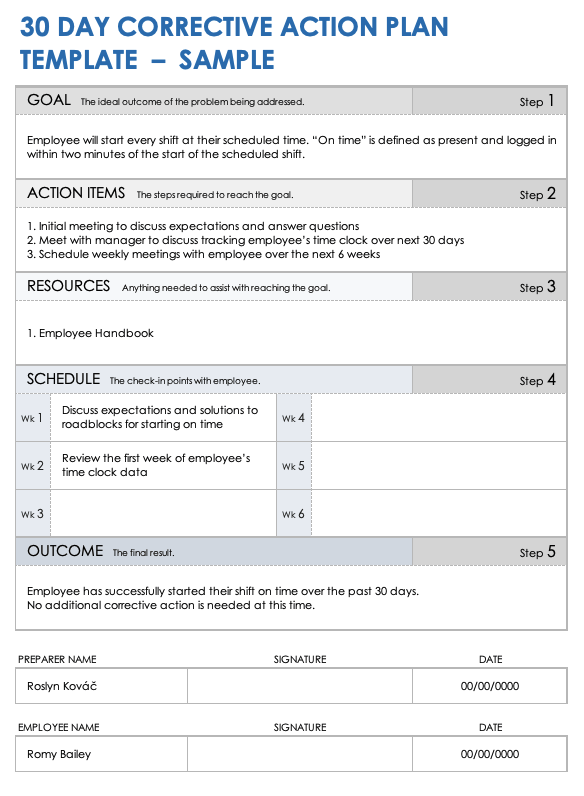

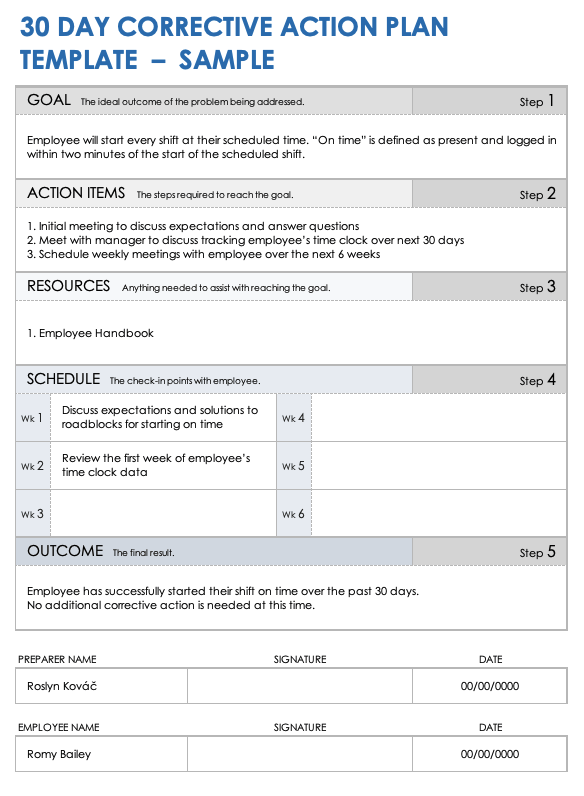

Consider the core elements that make such a form truly effective. It’s not just a blank sheet; it’s a guided process that walks the supplier through the necessary steps for a comprehensive response.

Key Components of an Effective Form

- Problem Description: A clear, concise statement of the non-conformance or issue, often including part numbers, quantities, and dates.

- Containment Actions: What immediate steps were taken to prevent further affected product from reaching customers or entering production.

- Root Cause Analysis: The most critical part, detailing the investigation into *why* the problem occurred, using tools like 5 Whys or Fishbone diagrams.

- Corrective Actions: Specific, measurable actions implemented to eliminate the root cause and prevent recurrence.

- Verification and Effectiveness: How the supplier will confirm their corrective actions are working and what measures are in place for ongoing monitoring.

- Due Dates and Signatures: Clear timelines for responses and responsible parties for accountability.

Implementing and Maximizing Your Supplier Corrective Action Process

Implementing a new supplier corrective action process doesn’t end with simply having a template. It requires clear communication, training, and consistent follow-up to ensure its effectiveness. Once you’ve issued a corrective action request (CAR) using your standardized form, the real work begins. Your team needs to be prepared to review the supplier’s response thoroughly, challenge assumptions if necessary, and collaborate with the supplier to ensure that the proposed actions are indeed effective and sustainable.

Effective communication is paramount throughout this process. Don’t just send the form and wait; consider a brief follow-up call or email to ensure the supplier understands the request and the urgency. Offer support and guidance if they struggle with specific sections, especially the root cause analysis. Remember, the goal is not just compliance, but genuine problem-solving and improvement, which often requires a partnership approach.

Once a completed form is returned, your quality team must verify the effectiveness of the implemented corrective actions. This might involve reviewing documentation, conducting on-site audits, or performing independent tests on future shipments. Without this verification step, you’re essentially taking the supplier’s word for it, which could lead to recurring issues down the line and erode trust in your quality system.

Leveraging technology can significantly enhance this process. While a paper-based or simple digital supplier corrective action response form template is a good start, dedicated quality management software can automate workflows, track due dates, send reminders, and centralize all corrective action data. This not only streamlines the process but also provides powerful analytics to identify trends, measure supplier performance, and drive continuous improvement across your entire supply chain, moving beyond just individual incident management to strategic quality enhancement.

A well-structured system for managing supplier quality issues is a cornerstone of operational excellence. By utilizing a robust supplier corrective action response form template, companies can ensure that every non-conformance is addressed systematically, from initial identification to verified resolution. This proactive approach minimizes disruptions, reduces costs associated with poor quality, and most importantly, protects your brand reputation.

Ultimately, investing in a clear, consistent, and collaborative corrective action process strengthens your relationships with suppliers, transforming them from mere vendors into true partners in your pursuit of quality. It’s a vital step towards building a resilient, high-performing supply chain that can adapt to challenges and consistently deliver value.