When a commercial truck breaks down, it’s not just an inconvenience; it’s a disruption that can halt operations and lead to significant financial losses. Getting that truck back on the road swiftly requires efficient communication and a clear understanding of the issue. Whether it’s a minor mechanical hiccup or a major engine failure, the speed and accuracy of reporting are paramount to minimizing downtime.

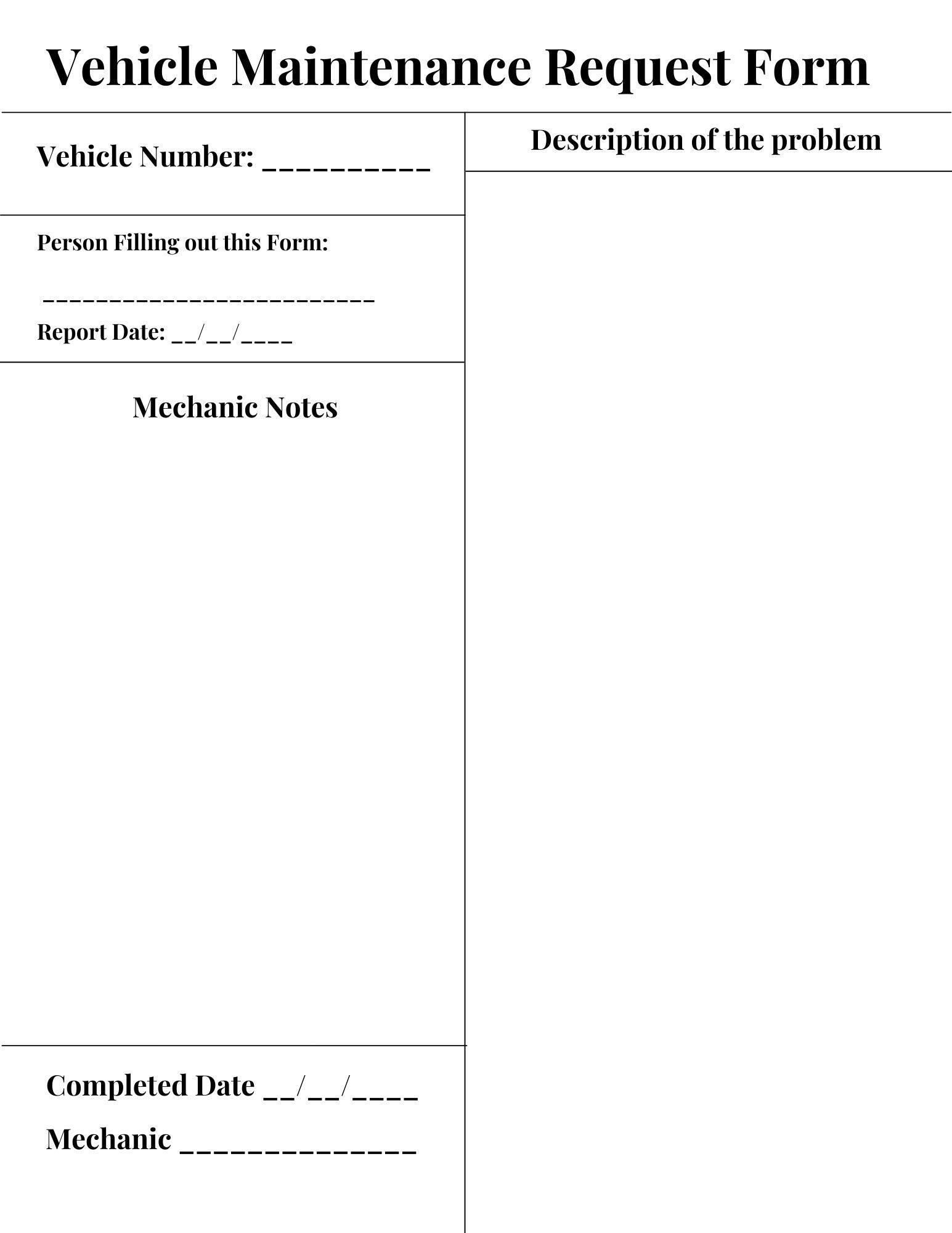

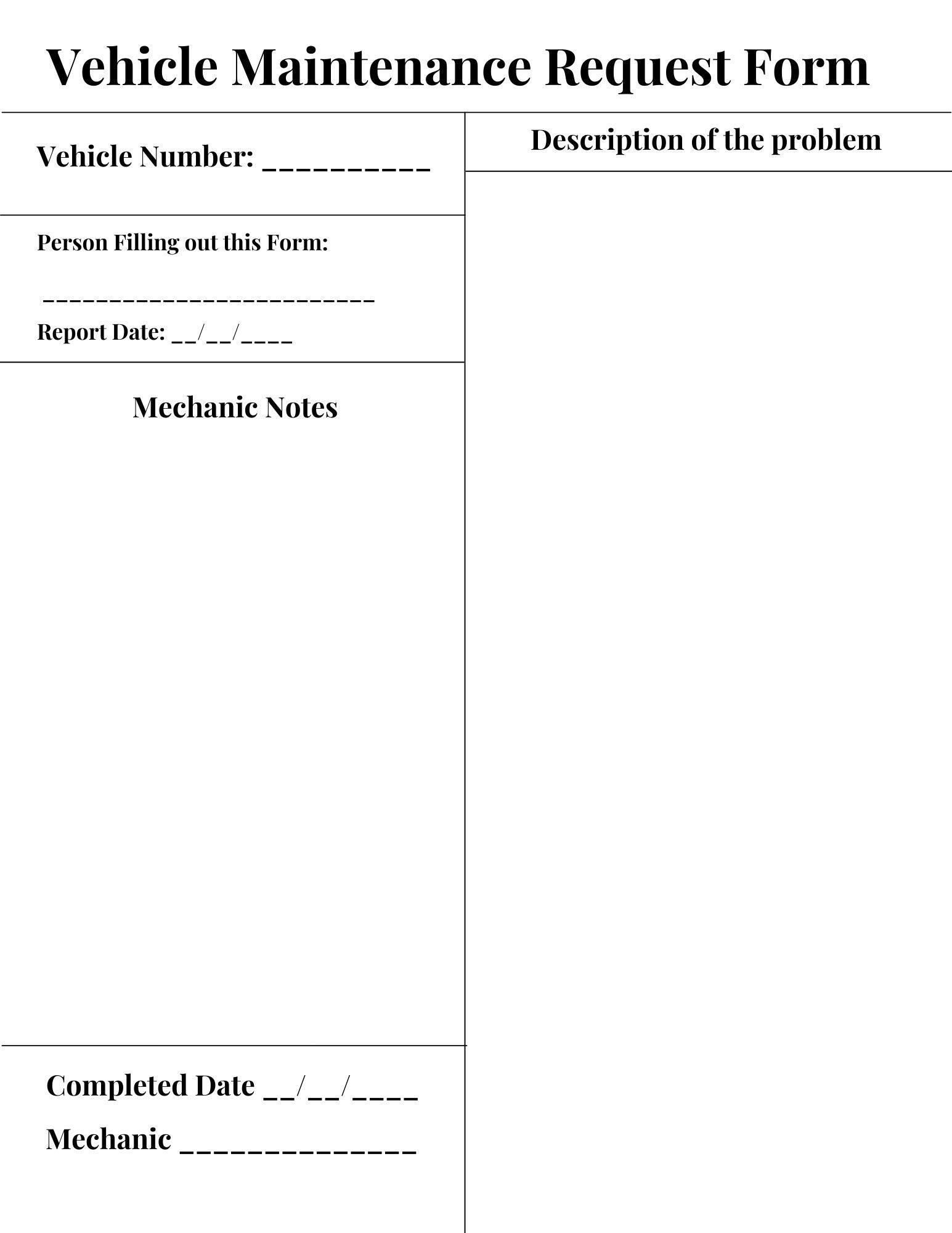

This is precisely where a well-designed truck repair request form template becomes an invaluable asset for any fleet manager or owner-operator. It serves as the crucial first step in a streamlined repair process, ensuring all necessary details are captured accurately from the outset. By providing a structured way to report issues, these forms help bridge the communication gap between drivers, dispatch, and the repair shop, setting the stage for a quick and effective resolution.

Why a Standardized Truck Repair Request Form is Essential

Implementing a standardized truck repair request form isn’t just about formality; it’s about establishing a clear, unambiguous channel for reporting vehicle issues. Imagine a scenario where a driver calls in a breakdown over the phone, trying to articulate a complex mechanical problem. Details can easily be missed, misinterpreted, or forgotten, leading to delays as the repair shop tries to diagnose the issue based on incomplete information. A well-structured form mitigates these risks by prompting the reporter for all critical data points upfront.

This consistency in reporting not only saves valuable time but also reduces the potential for costly errors. When mechanics receive a precise description of the problem, along with relevant vehicle details like mileage and recent maintenance, they can arrive better prepared, potentially with the right parts, or at least a more focused diagnostic plan. This proactive approach dramatically speeds up the repair process, getting your truck back into service faster and minimizing the financial impact of downtime.

Furthermore, these forms serve as vital documentation for your fleet’s maintenance history. Each completed form contributes to a comprehensive record of repairs, which can be invaluable for tracking recurring issues, identifying patterns in vehicle performance, and making informed decisions about preventative maintenance schedules. Over time, this data can highlight design flaws in specific truck models or reveal areas where driver training might be necessary to prevent certain types of wear and tear.

Beyond just facilitating repairs, a standardized form fosters a culture of accountability and professionalism within your operations. Drivers know exactly what information they need to provide, and repair technicians receive a clear, consistent brief. This systematic approach ensures that nothing is left to guesswork, leading to more efficient operations and ultimately, a more reliable fleet. It’s an investment in clear communication that pays dividends in operational efficiency and cost savings.

Key Information to Include in Your Form

- Vehicle Identification: Truck number, make, model, year, VIN, and current mileage.

- Driver Information: Name, contact number, and employee ID.

- Date and Time of Request: When the issue was reported.

- Location of Breakdown/Issue: Current location if immobile, or where the issue was first noticed.

- Problem Description: A detailed, clear description of the issue. Encourage drivers to use descriptive language and note any sounds, smells, or visual cues.

- Severity of Issue: Is the truck operational? Can it be driven to the shop? Is it a critical breakdown?

- Error Codes: Any dashboard warning lights or diagnostic trouble codes (DTCs).

- Requested Action: What the driver believes needs to be done (e.g., “check brakes,” “engine light on”).

- Authorization Signature: For approval of initial diagnostics or minor repairs.

Building Your Perfect Truck Repair Request Form Template

Creating an effective truck repair request form template doesn’t have to be complicated. You can start with a basic framework and then customize it to fit the specific needs of your fleet and operations. Consider the types of trucks you operate, the common issues you face, and the information your mechanics most frequently require. The goal is to make the form comprehensive enough to capture all necessary data without making it so long or complex that it becomes cumbersome for drivers to fill out, especially in a stressful breakdown situation.

Deciding between a physical paper form and a digital one is also a crucial step. Paper forms are readily accessible and don’t require a device or internet connection, which can be an advantage in remote locations. However, digital forms offer significant benefits in terms of data storage, accessibility, and automation. Many companies utilize mobile apps or web-based platforms that allow drivers to submit forms from their smartphones, often including features like photo attachments for visual context and GPS location tagging. These digital solutions can instantly notify relevant personnel and automatically populate repair logs, greatly enhancing efficiency.

Regardless of whether you choose a paper or digital format, prioritize user-friendliness. The layout should be logical and intuitive, guiding the person filling it out through each field clearly. Use clear headings, checkboxes, and drop-down menus where possible to minimize typing and ensure consistent responses. If it’s a digital form, test it on various devices to ensure responsiveness and ease of use. A form that is difficult or frustrating to complete is less likely to be used correctly or consistently.

Finally, effective implementation involves more than just creating the form. It requires clear communication with your drivers about its purpose and how to use it. Provide brief training sessions and make sure they understand the importance of providing accurate and complete information. Regular review of submitted forms can help you identify areas for improvement in the form itself or in your repair process. Over time, this iterative approach will ensure your truck repair request form template remains a powerful tool for efficient fleet management.

Adopting a systematic approach to reporting truck issues can dramatically improve your operational efficiency and minimize costly downtime. By standardizing the information captured at the very beginning of a repair cycle, you empower your maintenance team to act quickly and accurately. This foresight ensures that every minute counts when a valuable asset like a commercial truck is out of commission.

Ultimately, investing time in developing and refining a robust form like a truck repair request form template is an investment in the longevity and reliability of your fleet. It promotes clear communication, facilitates prompt repairs, and builds a valuable historical record, contributing significantly to the smooth operation and success of your business.